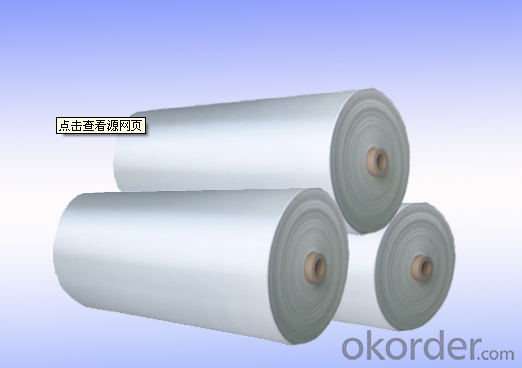

Fiberglass Mat Tissue - E-Glass Fiberglass Woven Roving, 400g, 2000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

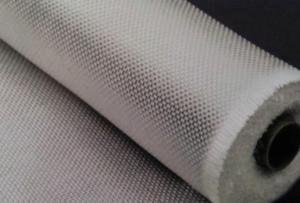

Structure of woven roving Description

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

Woven roving Images

Woven roving Specification: weight& thickness

Normal type | EWR800-1000 | Test Standard |

Apperance | Good | GB/T 18370-2001 |

Density(warpxweft)(end/cm) | 1.8 X 1.5 | GB/T 7689.2-2001 |

Tex (warpxweft) | 2400x2400 | ISO1889 |

Moisture content(%) | ≤0.10 | ISO3344 |

Loss on ignition(%) | 0.40-0.80 | ISO1887 |

Glass | E-glass | N/A |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: Can fiberglass mat tissue be used for lightweight construction?

- Yes, fiberglass mat tissue can be used for lightweight construction. Fiberglass mat tissue is a thin and lightweight material made up of randomly oriented glass fibers bonded together with a binder. It is commonly used as a reinforcement material in composite laminates and is known for its excellent strength-to-weight ratio. In lightweight construction, where weight reduction is a key consideration, fiberglass mat tissue can be an ideal choice. Its low weight adds minimal additional load to the structure while still providing sufficient strength and durability. The random orientation of the fibers in the mat tissue ensures that the load is evenly distributed, further enhancing its strength properties. Additionally, fiberglass mat tissue is easy to handle and can be easily molded into various shapes and forms. This flexibility makes it suitable for applications in lightweight construction, such as in the production of lightweight panels, wall partitions, and roof structures. The material can also be used in combination with other lightweight materials, such as foam cores or honeycomb structures, to further enhance its lightweight properties. Overall, fiberglass mat tissue is a versatile material that can be effectively used for lightweight construction. Its lightweight nature, combined with its strength and durability, make it a suitable choice for various applications where weight reduction is a priority.

- Q: How is fiberglass mat tissue used in the production of windshields?

- The unique properties and functions of fiberglass mat tissue make it a crucial component in windshield production. To strengthen and increase the durability of the glass, manufacturers use fiberglass mat tissue as a reinforcement material. In the manufacturing process, a layer of fiberglass mat tissue is inserted between two layers of glass to create a laminated structure. This layer acts as a barrier, preventing the glass from shattering upon impact and holding it together for the safety of the vehicle occupants. By serving as a reinforcing material, fiberglass mat tissue improves the mechanical properties of the windshield. It enhances the impact resistance, reducing the likelihood of cracks or chips caused by stones, debris, or other objects. This reinforcement also provides structural integrity, allowing the windshield to withstand extreme weather conditions and vibrations without affecting its functionality. Moreover, fiberglass mat tissue aids in reducing noise transmission and vibrations. Its sound-damping properties contribute to a quieter and more comfortable driving experience by minimizing external noise from entering the vehicle cabin. Additionally, the use of fiberglass mat tissue enables the production of curved windshields. The material's flexibility allows it to conform to different shapes and contours, enabling manufacturers to create windshields with customized designs and improved aerodynamics. In conclusion, fiberglass mat tissue plays a vital role in windshield production. Its reinforcement properties enhance the strength and impact resistance of the glass, ensuring the safety of vehicle occupants. It also contributes to a quieter driving experience and enables the production of curved windshields with improved aerodynamics.

- Q: Is fiberglass mat tissue resistant to oil and grease?

- Yes, fiberglass mat tissue is resistant to oil and grease. The composition of fiberglass mat tissue consists of fine strands of glass fibers bonded together with a resin. This resin acts as a barrier that prevents oil and grease from penetrating through the mat tissue, making it resistant to these substances. Additionally, fiberglass itself is known for its non-reactive properties, which further enhances its resistance to oil and grease. Therefore, fiberglass mat tissue is an ideal material for applications where contact with oil and grease is expected, such as in industrial settings or automotive components.

- Q: Can fiberglass mat tissue be used for insulation in cryogenic applications?

- Yes, fiberglass mat tissue can be used for insulation in cryogenic applications. Fiberglass is a versatile material known for its excellent thermal insulation properties. It has a low thermal conductivity, which means it is highly effective at reducing heat transfer. This makes it suitable for cryogenic applications where maintaining extremely low temperatures is crucial. Additionally, fiberglass is non-combustible and does not absorb moisture, making it ideal for cryogenic environments. It can be used as a layer of insulation in cryogenic storage tanks, pipes, and other equipment to prevent heat transfer and maintain the desired low temperatures.

- Q: What is the expected lifespan of fiberglass mat tissue?

- The lifespan of fiberglass mat tissue can differ based on several factors, including material quality, exposure conditions, and specific usage. Nonetheless, fiberglass mat tissue is renowned for its longevity and durability. When manufactured and installed correctly, fiberglass mat tissue has the potential to endure for many decades. It possesses resistance against decay, corrosion, and various chemicals, making it suitable for diverse industries and applications. Furthermore, fiberglass mat tissue is esteemed for its strength and capacity to withstand high temperatures. Nevertheless, it is crucial to acknowledge that prolonged exposure to harsh environmental elements, such as extreme temperatures, UV radiation, and moisture, may gradually degrade the material. Regular maintenance and appropriate care can aid in prolonging the lifespan of fiberglass mat tissue. In conclusion, while it remains challenging to determine an exact anticipated lifespan for fiberglass mat tissue, it is generally perceived as a long-lasting material when utilized and maintained properly.

- Q: Is fiberglass mat tissue suitable for insulation in laboratories?

- Yes, fiberglass mat tissue is suitable for insulation in laboratories. It offers excellent thermal insulation properties, is resistant to high temperatures, and provides effective sound insulation. Additionally, it is non-combustible and chemically inert, making it ideal for laboratory environments where safety and performance are crucial.

- Q: Can fiberglass mat tissue be used in automotive manufacturing?

- Yes, fiberglass mat tissue can be used in automotive manufacturing. It is commonly used as a reinforcement material for various components such as body panels, bumpers, and interior parts. It provides strength, durability, and excellent resistance to corrosion and heat, making it an ideal choice for automotive applications.

- Q: Can fiberglass mat tissue be used for repairing fiberglass surfboards?

- Yes, fiberglass mat tissue can be used for repairing fiberglass surfboards. It is a common material used in surfboard repairs as it provides added strength and stability to damaged areas.

- Q: Can fiberglass mat tissue be used for making lightweight flooring?

- Yes, fiberglass mat tissue can be used for making lightweight flooring. Fiberglass mat tissue is a material that is commonly used in construction and manufacturing industries for its strength, durability, and lightweight properties. It is made by bonding fine fiberglass strands together with a binder, which results in a thin, flexible, and lightweight material. When used in flooring applications, fiberglass mat tissue can provide several advantages. Firstly, its lightweight nature makes it easier to handle and install, reducing the overall weight of the flooring system. This can be particularly beneficial in applications where weight is a concern, such as in aircraft or mobile homes. Additionally, fiberglass mat tissue is known for its excellent strength-to-weight ratio, making it a suitable material for creating lightweight yet strong flooring. It can provide reinforcement and improve the structural integrity of the flooring, making it more resistant to cracking, warping, or other forms of damage. Furthermore, fiberglass mat tissue is resistant to moisture, chemicals, and fire, making it a suitable choice for areas where these factors are present, such as bathrooms, kitchens, or industrial settings. It also offers good insulation properties, which can help in maintaining a comfortable indoor environment and reducing energy consumption. Overall, fiberglass mat tissue can be an excellent choice for making lightweight flooring due to its strength, durability, moisture resistance, and insulation properties. However, it is important to consider other factors such as the specific requirements of the flooring application, the load-bearing capacity, and the necessary certifications or standards before finalizing the use of fiberglass mat tissue in a flooring project.

- Q: Is fiberglass mat tissue resistant to corrosion?

- Indeed, corrosion is not a concern for fiberglass mat tissue as it is comprised of non-metallic elements like glass fibers, unlike metals which are susceptible to rust and corrosion. This quality renders fiberglass mat tissue highly suitable for various purposes that demand resistance against corrosion, such as reinforcing concrete structures within the construction sector or for boat building in the marine industry. Furthermore, fiberglass mat tissue exhibits resistance towards chemicals, moisture, UV rays, and extreme temperatures, thereby augmenting its strength and longevity.

Send your message to us

Fiberglass Mat Tissue - E-Glass Fiberglass Woven Roving, 400g, 2000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords