Fiberglass Mat Tissue E Glass Fiber Woven Roving for Boat Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

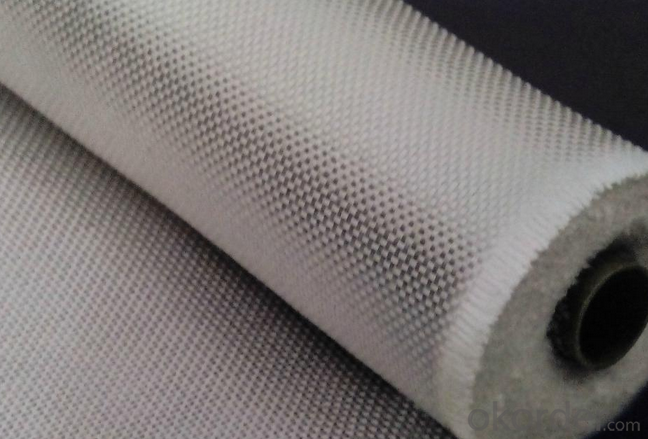

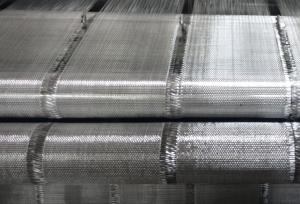

Structure of woven roving Description

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Main Features of the woven roving

1) Woven roving is a kind of evenly distributed material which owns high strength on both side with high intensity, the fiber content and strength is even higher during the production of FRP products.

2) Benefit from the production procedure and the material itself, the fabric maintains high percentage of its material strength, and also very easy for the resin to penetrate.

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

1. Your inquiry will be replied within 24hours

2. Well-trained and experienced staffs will answer all your inquiries at first time..

3. All our products have warranties.

4. Offering the support to solve the problem during the application or selling period.

5. Good quality with competitive price.

6. The same quality of samples and mass products is granted.

- Q: Is fiberglass mat tissue compatible with different curing methods?

- Indeed, diverse curing methods are compatible with fiberglass mat tissue. This versatile material can be utilized in various curing processes, including hot press curing, autoclave curing, and vacuum bag curing. Specifically engineered to be compatible with different resins and curing temperatures, the mat tissue is capable of enduring the curing process without any detrimental consequences. Furthermore, the mat tissue is designed to possess excellent wet-out properties, enabling it to effectively bond with the resin during the curing process. Ultimately, fiberglass mat tissue proves to be a fitting option for a wide array of curing methods and can be effectively employed in numerous applications.

- Q: What are the different surface finishes available for fiberglass mat tissue?

- There are several different surface finishes available for fiberglass mat tissue, each with its own unique properties and benefits. One common surface finish is a smooth or fine finish, which provides a smooth and even texture to the fiberglass mat tissue. This finish is often used when a high-quality surface appearance is desired, such as in cosmetic applications or when the fiberglass mat will be painted or coated. Another option is a textured or coarse finish, which adds texture and grip to the surface of the fiberglass mat tissue. This finish is often used in applications where increased friction or traction is required, such as in flooring or decking materials. A third option is a fire-retardant finish, which is designed to provide increased fire resistance to the fiberglass mat tissue. This finish is commonly used in applications where fire safety is a concern, such as in building materials or insulation. Additionally, there are finishes available that offer specific properties such as increased chemical resistance, UV resistance, or enhanced durability. These finishes are often used in applications where the fiberglass mat tissue will be exposed to harsh environmental conditions or chemicals. Overall, the choice of surface finish for fiberglass mat tissue will depend on the specific application and desired properties. By selecting the appropriate finish, manufacturers can ensure that the fiberglass mat tissue meets the required performance standards and delivers the desired performance characteristics.

- Q: Does fiberglass mat tissue provide good fire protection?

- No, fiberglass mat tissue does not provide good fire protection.

- Q: What are the different thickness tolerances for fiberglass mat tissue?

- The thickness tolerances for fiberglass mat tissue can differ depending on the manufacturer and product specifications. Generally, fiberglass mat tissue is offered in a range of thickness tolerances from 0.5 millimeters (mm) to 3 mm. The tolerance represents the acceptable range of thickness variation within a product. For instance, a fiberglass mat tissue with a thickness tolerance of +/- 0.5 mm means that the actual thickness can deviate by up to 0.5 mm in either direction from the specified thickness. The required tolerance for a specific application depends on the intended use and desired precision. Thicker fiberglass mat tissues with smaller tolerances are commonly utilized in applications that demand greater strength and durability, like reinforcing concrete in the construction industry or manufacturing composite materials. Conversely, thinner fiberglass mat tissues with larger tolerances may be employed in applications where flexibility and conformability take precedence, such as insulation or soundproofing in the automotive industry. To obtain accurate information regarding available thickness tolerances for fiberglass mat tissue, it is crucial to refer to the manufacturer's specifications or contact a supplier. These tolerances can significantly vary based on the specific product and supplier.

- Q: Can fiberglass mat tissue be used for reinforcing wind turbine blades?

- Yes, fiberglass mat tissue can be used for reinforcing wind turbine blades. It is commonly utilized in the manufacturing process as it provides strength, durability, and flexibility to the blades, making them more capable of withstanding the forces and stresses experienced during operation.

- Q: How does fiberglass mat tissue compare to fiberglass insulation batts?

- Fiberglass mat tissue and fiberglass insulation batts serve different purposes and have distinct characteristics. Fiberglass mat tissue is primarily used as a reinforcement material in various applications such as roofing, wall coverings, and composite materials. It provides strength, durability, and improved dimensional stability to the finished product. On the other hand, fiberglass insulation batts are specifically designed for thermal insulation purposes, typically used in walls, ceilings, and attics to prevent heat transfer. They are engineered to trap air pockets within the material, providing excellent thermal resistance. While both products are made from fiberglass and offer certain insulation properties, their specific applications and performance differ significantly.

- Q: Is fiberglass mat tissue suitable for sound absorption?

- Yes, fiberglass mat tissue is suitable for sound absorption. Fiberglass has excellent acoustic properties, making it an effective material for reducing noise levels and improving sound quality in various applications. The fibrous structure of the mat tissue provides a high surface area to absorb sound waves, converting them into heat energy. This makes it an ideal material for soundproofing walls, ceilings, and floors in buildings, as well as for use in automotive, industrial, and marine applications. Additionally, fiberglass mat tissue is lightweight, easy to install, and has good durability and fire resistance, further enhancing its suitability for sound absorption purposes.

- Q: What are the potential health hazards associated with working with fiberglass mat tissue?

- Potential health hazards associated with working with fiberglass mat tissue include skin irritation, respiratory issues such as coughing and wheezing, eye irritation, and allergic reactions. Long-term exposure to fiberglass fibers can also lead to a condition called fiberglass lung, which is characterized by chronic coughing, chest tightness, and difficulty breathing. It is important to use proper protective equipment, such as gloves, goggles, and a respirator, when working with fiberglass mat tissue to minimize these risks.

- Q: Can fiberglass mat tissue be used for automotive applications?

- Indeed, automotive applications can benefit from the utilization of fiberglass mat tissue. This versatile material finds extensive use within the automotive industry for a multitude of purposes. In particular, it serves as a reinforcement component for composite parts like bumpers, body panels, and interior elements. The exceptional strength and lightweight attributes of fiberglass mat tissue render it a prime selection for automotive applications, effectively augmenting vehicle performance and durability. Moreover, this material offers superb sound insulation and vibration damping properties, which are essential for enhancing comfort and reducing noise in automobiles. As a whole, fiberglass mat tissue stands as a dependable and widely adopted material across the automotive industry, playing a pivotal role in the creation of high-quality and efficient vehicles.

- Q: Can fiberglass mat tissue be used for reinforcing concrete structures?

- Yes, fiberglass mat tissue can be used for reinforcing concrete structures. Fiberglass mat tissue is a thin, lightweight material made from woven glass fibers. It offers high strength-to-weight ratio and excellent corrosion resistance, making it an ideal choice for reinforcing concrete structures. When used as reinforcement in concrete, fiberglass mat tissue is typically embedded into the concrete mix. It helps improve the tensile strength and ductility of the concrete, preventing cracks and increasing its overall durability. Fiberglass mat tissue is commonly used in applications such as precast concrete panels, concrete pipes, and concrete overlays. It provides reinforcement to these structures, allowing them to withstand heavy loads and resist cracking, especially in areas where concrete alone may not be sufficient. Furthermore, fiberglass mat tissue is also resistant to chemicals and environmental factors, making it suitable for use in harsh conditions or exposed environments. It does not corrode or rust like traditional steel reinforcements, ensuring the longevity and structural integrity of the concrete structure. Overall, fiberglass mat tissue is a reliable and effective option for reinforcing concrete structures. Its lightweight nature, high strength, corrosion resistance, and durability make it a popular choice in the construction industry.

Send your message to us

Fiberglass Mat Tissue E Glass Fiber Woven Roving for Boat Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords