Fiberglass Foam Sandwich Panels - EPS Sandwich Roof Panel for Hot Sell and Good Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Sandwich Panel

Sandwich panel is composed of 2 layers of weather-proof colored steel sheets and jetted the hard forms of polyurethane between 2 layers which feature fireproof materials. Sandwich panel is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purifications workshops, etc, Sandwich panel has features temp-keeping, heat insulation, weight-bearing, weatherproof with the rich colorfulness and good appearance.

2.Main Features of the Sandwich Panel

1) Our EPS sandwich panel has the following characteristics:light dead weight, high mechanical strength, excellent shearing resistant performance, strong corrosion resistance, high durability, and weather fastness, etc.

2) The sandwich panel has excellent insulating performance: heat insulation, sound insulation, waterproof performance, etc.

3) It is easy to install and can be used many times over.

4) Nowadays, the EPS sandwich panel is widely used for cleaning workshops, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

5) Apart from EPS sandwich panels, Wiskind also offers rock wool sandwich panels, glass wool sandwich panels, PU sandwich panels, honeycomb sandwich panels.

6) These products have all passed ISO9001 and ISO14001 certification. Due to their high quality and low price, they are well received by our customers in Russia, Australia, Angola, Congo, and Korea, etc.

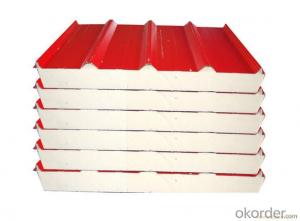

3. Sandwich Panel Images

4. Sandwich Panel l Specification

Effective width Wall panel: 950mm 1150mm 1200mm Roof panel: 950mm 980mm

Length According to customer's request

Materials Polystyrene foam board(EPS), Color steel sheet

Structure Upper and lower layer: Color steel sheet

Middle: polystyrene foam board

Thickness Color steel sheet: 0.3-0.6mm

Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm

The polystyrene density 8-20kg/m3

Conventional color RAL standard

Character Light in weight, heat insulation, water resistant, green and environmental

Use various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc.

5.Advantages of Sandwich Panels

1) Heat and sound insulation: The outer steel sheets can maintain the lastingness of the color of the building, and reduce the solar radiation and keep the appropriate indoor temperature. The high quality heat insulation materials are made with the adoption of polyurethane PU and (PIR) polyisocyanurate resin acid hydrogen containing no Chloro-fluoro-carbons (CFC).

2) A degree inflaming retarding: This system can effectively prevent the fire and prevent the fire from spreading during the cross construction and during the use of the boards

3) Environment protection: By learning after the successful experience in environment protection constructions from companies home and abroad and through our scientific analysis, we objectively bear the idea of “low carbon designing, environmental building materials and energy-saving technology” in mind.

4) Super-low heat conductivity: The lowest heat conducting coefficient of the heat insulation boards ensures that, under the condition that the thinnest heat insulation materials are used; the system can meet the energy-saving requirement and offer the strongest basic guarantee to meet the requirement of high standard heat insulation

5) Easily and quick installation

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

2) A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

3) How to guarantee the quality of the products?

4) We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5) How long can we receive the product after purchase?

6) In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Air conditioning year after the addition of Calvary is not the reason for refrigeration

- It is said that the earth will produce a carcinogenic material, in the sixth floor above will not have an impact on people, you are not taking into account the life on the moon ah

- Q: Reinforced concrete and metal sandwich board how much difference

- Tower crane driver, scaffolding type of work, all kinds of welding workers

- Q: This is not required, the requirements of the interval of the wall to meet the fire requirements of fire resistance or fire time requirements. The Applicable Scope of Molybdenum Sandwich Panel

- Color steel sandwich panels have the effect of thermal insulation, these two types of panels can be used for houses and workshops, are able to waterproof

- Q: Are sandwich panels suitable for food kiosks?

- Yes, sandwich panels are suitable for food kiosks. Sandwich panels are commonly used in the construction of food kiosks due to their durability, insulation properties, and ease of installation. They provide a hygienic and easy-to-maintain surface, making them ideal for food-related businesses. Additionally, sandwich panels offer flexibility in design and can be customized to meet specific requirements, making them a popular choice for food kiosks.

- Q: Can sandwich panels be used for noise barriers?

- Sandwich panels are indeed a viable option for noise barriers. Typically, these panels consist of two outer layers made from rigid materials like metal or wood, with an insulating layer in between. This insulating layer functions to absorb and dampen sound waves, making sandwich panels an effective solution for noise barriers. The insulating material used in sandwich panels can vary, with options such as mineral wool or polyurethane foam, both of which possess excellent sound absorption properties. These materials are specifically designed to trap and dissipate sound energy, effectively preventing it from passing through the barrier and reducing noise levels on the opposite side. When it comes to noise barriers, sandwich panels can be customized to meet specific requirements for noise reduction. By adjusting the thickness and density of the insulating layer, the desired level of sound insulation can be achieved. Additionally, the outer layers can be designed to either reflect or absorb sound, depending on the desired acoustic performance and aesthetic preferences. There are several advantages to using sandwich panels for noise barrier applications. Firstly, they are lightweight, making them easy to install and transport. Furthermore, they possess a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Lastly, sandwich panels can be engineered to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. To summarize, sandwich panels are an ideal choice for noise barriers due to their sound absorption properties, customization options, and durability. They effectively reduce noise levels, creating a quieter environment for various applications, including highways, factories, residential areas, and commercial buildings.

- Q: How the exterior of the house is made of rock wool color steel sandwich panels

- Construction, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, scaffolding, Erecting outside the scaffolding materials expected ribs of the late section of the dwarf light dog chupu count, template support frame, shelf safety operation technology. Zibu type construction fastener, by the two holes in the diameter of the child is significantly different, the female fastener riveting, two fasteners on the lower cover are steel stamping parts, cover, under the cover with ribs , The upper and lower cover of the middle part of the arc inward convex, the arc-shaped convex surface and the upper and lower cover on both sides of the same cylindrical surface, the child, the female fastener nut on the same size. The fastener is used to build construction scaffolding, building fence, planting greenhouses, etc., can be connected to different diameter pipe, can be rotated angle, wide range of applications, and the fastener weight, bending strength and good steel, , Easy to use.

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Height of 24m below the double scaffold can be flexible connection, but must be used to withstand the tension and pressure structure.

- Q: Can sandwich panels be used for ticket booths?

- Ticket booths can indeed utilize sandwich panels. Composed of two slim outer layers and a thermal insulating core material, sandwich panels possess a reputation for their robustness, longevity, and energy efficiency. These characteristics render them an excellent selection for diverse construction purposes, including ticket booths. By offering insulation against extreme temperatures, reducing noise, and providing fire resistance, sandwich panels offer essential attributes for ticket booths. Furthermore, their lightweight nature allows for effortless transportation and installation. They can be tailor-made to accommodate specific design specifications and require minimal maintenance. Consequently, sandwich panels emerge as a fitting and pragmatic choice for ticket booths.

- Q: Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- Door scaffolding, fastener steel scaffolding, bowl button steel pipe scaffolding, socket-type steel scaffolding. It is best to pay for the work of the scaffolding to learn the preparation of scaffolding program

- Q: Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- The price of the foam board depends on its density, the higher the density, the more expensive the price

Send your message to us

Fiberglass Foam Sandwich Panels - EPS Sandwich Roof Panel for Hot Sell and Good Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords