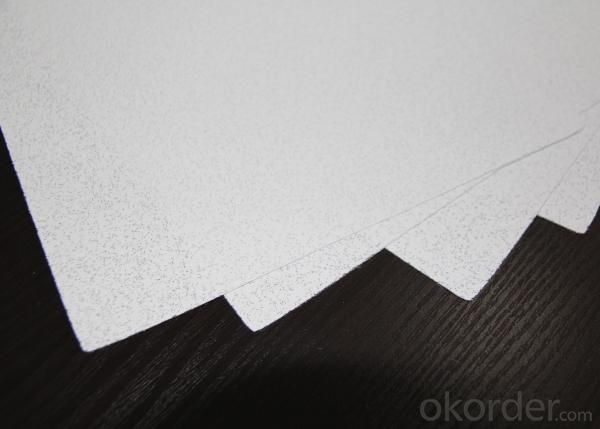

Fiberglass Facing White Spray Coating Tissue 700#-W

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 30000M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Spray Coating Tissue

700W

|

Specification | ||

|

ITEM |

UNIT |

VALUE |

|

Weight |

g/m2 |

380 |

|

Thickness |

mm |

0.55 |

|

Property ofFire Retardant |

|

Non-ignitability A level |

|

Tensile Strength MD |

n/5cm |

150 |

|

Tensile Strength CMD |

n/5cm |

110 |

SIZE:

Width: 0.6m---1.3m

Length: 50m-300m

Core I.D.: 3"(76mm ±1)

Based on order, special sizes are also available.

MSDS:No harm for body and environment, non-volatile product.

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: ±0.5%.

3. The products should be stored at room temperature, kept from wet and kept away heat source.

4. Good appearance without stain, oxidation, mildew.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

Usage/Applications of Spraying Coating Tissue

Fiberglass facing is good at fireproof, mildew resistant, damp proof and strong air permeability. After laminated with glass wool or rock wool, the physical properties is excellent such as heat preservation, noise elimination, fire retardant, extinction, etc.

Packaging & Delivery of Spraying Coating Tissue

Each roll is packed by water-proof film

- Q: Is it possible to utilize black fiberglass tissue for the purpose of soundproofing?

- <p>Yes, black fiberglass tissue can be used for sound insulation. It is a popular material due to its lightweight, flexibility, and ability to absorb sound. Fiberglass is effective in reducing noise transmission by disrupting sound waves and preventing them from passing through. It is commonly used in walls, ceilings, and floors to improve acoustic performance in residential, commercial, and industrial settings. However, it's important to handle fiberglass with care due to its potential health risks and to ensure proper installation for maximum effectiveness.</p>

- Q: Is it possible to recycle black fiberglass tissue and use it to create new products?

- <p>Yes, black fiberglass tissue can be recycled into new products. The recycling process involves shredding and grinding the material to separate the glass fibers from the resin. The fibers can then be used as a reinforcing material in composites, while the resin can be processed for other applications. However, the recycling of black fiberglass is less common due to the difficulty in separating the fibers from the dark resin, which can affect the color of new products. Despite this, advancements in recycling technology are making it more feasible to recycle black fiberglass and incorporate it into new manufacturing processes.</p>

- Q: What distinguishes black fiberglass tissue from other types of fiberglass tissue in terms of color, properties, and applications?

- <p>Black fiberglass tissue is distinguished by its color, which is typically achieved through the addition of pigments during the manufacturing process. This coloration can enhance UV resistance and provide a more aesthetically pleasing appearance in certain applications. Compared to other types of fiberglass tissue, such as white or colored ones, black fiberglass may also exhibit slightly different thermal properties due to the pigmentation. However, the core properties like strength, flexibility, and insulation capabilities remain largely the same across different colored fiberglass tissues. The choice between black and other types often comes down to specific industry requirements or aesthetic preferences.</p>

- Q: This question asks for the methods to clean and maintain black glass fiber cloth.

- <p>To clean and maintain black glass fiber cloth, follow these steps: 1. Use a soft brush or vacuum cleaner with a brush attachment to remove loose dirt and dust. 2. For stubborn stains, mix a mild detergent with warm water and gently dab the affected area with a soft cloth. Avoid rubbing or scrubbing as it may damage the fibers. 3. Rinse the area with clean water and pat dry with a soft towel. 4. Avoid using harsh chemicals, bleach, or high heat, as they can degrade the fibers. 5. Regularly inspect the cloth for signs of wear and tear, and replace it if necessary to maintain its performance and appearance.</p>

- Q: This question asks for a comparison between black fiberglass tissue and other sound insulation materials, focusing on their properties and effectiveness.

- <p>Black fiberglass tissue is a type of sound insulation material known for its lightweight, flexibility, and high sound absorption capabilities. Compared to other materials, it offers excellent thermal insulation and resistance to moisture and fire. However, it may not be as dense or heavy-duty as some alternatives like mass-loaded vinyl or certain types of acoustic foam, which can provide better soundproofing in high-noise environments. Black fiberglass tissue is also sensitive to physical damage, which can reduce its effectiveness over time. It's important to consider the specific application and environmental factors when choosing the right sound insulation material.</p>

- Q: What are the ecological effects associated with the utilization of black fiberglass tissue?

- <p>The environmental impact of using black fiberglass tissue is primarily associated with its production and disposal. During production, it can release harmful chemicals and particulates into the air, contributing to air pollution. Additionally, fiberglass is not biodegradable, which means it persists in landfills and can leach chemicals into the soil and groundwater, potentially harming ecosystems. The dark color of black fiberglass may also absorb more heat, which could contribute to the urban heat island effect. However, it's important to note that the environmental impact can be mitigated through proper waste management and recycling programs, which are becoming more prevalent as awareness of environmental issues grows.</p>

- Q: This question asks about the application of glass fiber paper in construction projects, seeking to understand its role and how it is utilized.

- <p>Glass fiber paper is used in construction projects for various purposes due to its high strength, durability, and resistance to heat and moisture. It is often used as a reinforcing material in concrete, providing additional strength and preventing cracks. It can also be used as a barrier to prevent water and moisture from penetrating walls and ceilings, acting as a vapor barrier. In insulation applications, it helps to reduce heat transfer and improve energy efficiency. Glass fiber paper is also used in the production of fiberglass, which is used for roofing, insulation, and other structural components. It's important to follow safety guidelines when handling glass fiber paper due to its potential health risks.</p>

- Q: Are there any health concerns associated with fiberglass facing?

- Yes, there are health concerns associated with fiberglass facing. Fiberglass is made up of tiny fibers that can become airborne when disturbed, such as during installation or removal. Inhalation of these fibers can irritate the respiratory system and cause symptoms like coughing, chest tightness, and difficulty breathing. Prolonged exposure to fiberglass fibers can also lead to a serious lung condition called fibrosis, where the lung tissues become scarred and stiff. Additionally, fiberglass can cause skin irritation and allergic reactions when it comes into direct contact with the skin. The small fibers can penetrate the skin, leading to itching, redness, and rash. To minimize the health risks associated with fiberglass, it is important to take precautions when working with it. This includes wearing protective clothing, gloves, goggles, and a respirator to prevent inhalation of the fibers. It is also crucial to properly clean up any fiberglass dust or debris to avoid further exposure. If you suspect that you have been exposed to fiberglass and are experiencing persistent respiratory or skin symptoms, it is recommended to seek medical attention for proper evaluation and treatment.

- Q: What distinguishes black fiberglass from other types of glass fiber in terms of properties and applications?

- <p>Black fiberglass is a type of glass fiber that has been treated with a black pigment or dye, which gives it a distinct appearance and specific properties. Unlike other types of glass fibers which can be clear or have other colors, black fiberglass is primarily used for aesthetic purposes or to absorb light, reducing glare and reflections. It is often used in applications where a dark, non-reflective surface is desired, such as in some types of automotive components, exterior building materials, or in certain industrial settings. Other types of glass fibers may be used for their strength, insulation properties, or electrical non-conductivity, and are not necessarily colored. The choice between black fiberglass and other types of glass fibers depends on the specific requirements of the application in terms of appearance, performance, and functionality.</p>

- Q: Can fiberglass facing be used in high-temperature applications?

- Using fiberglass facing in high-temperature applications is not possible. Fiberglass is a reinforced plastic material, renowned for its remarkable thermal insulation and resistance to corrosion. Nonetheless, it possesses a low melting point, rendering it unsuitable for high-temperature settings. High temperatures can cause fiberglass to melt, distort, or deteriorate, thereby jeopardizing its structural soundness and insulation capabilities. To guarantee safety and achieve optimal performance, it is crucial to select alternative materials explicitly engineered for high-temperature environments, such as ceramic fiber or metal facing.

1. Manufacturer Overview

| Location | Jangsu, China |

| Year Established | 1999 |

| Annual Output Value | Above US$0.3 billion |

| Main Markets | 0.00% Mid East 15.00% Northern Europe 15.00% North America 10.00% Eastern Asia 20.00% Africa 0.00% Eastern Europe 20.00% Southeast Asia 0.00% Oceania 0.00% Western Europe 0.00% Southern Europe 0South east asia;North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Fiberglass Facing White Spray Coating Tissue 700#-W

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 30000M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords