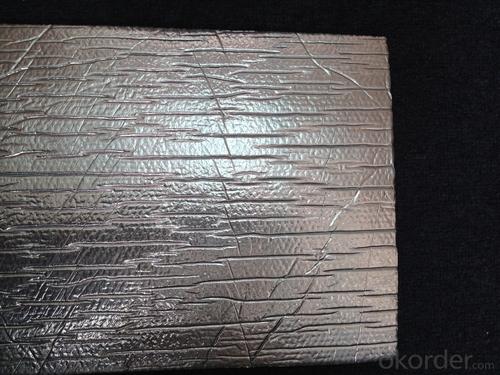

Fiberglass Facing Flexible Ducts Bubble Aluminum

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: Is it possible to recycle black fiberglass tissue in an environmentally friendly manner?

- <p>Yes, black fiberglass tissue can be recycled in a sustainable way. The process involves separating the fiberglass from other components, cleaning, and shredding it into smaller pieces. Recycled fiberglass can be used as a filler in new composite materials, reducing the need for raw materials and promoting sustainability. However, it's important to note that not all recycling facilities may accept black fiberglass due to the dye, which can complicate the recycling process. Proper disposal and recycling guidelines should be followed to ensure the material is handled correctly.</p>

- Q: Is it possible to utilize black fiberglass scraps in the creation of new products made from recycled materials?

- <p>Yes, you can use black fiberglass scraps to make new products from recycled materials. Fiberglass recycling is possible, and it involves processes like shredding and grinding the scraps to create a material that can be used in new products. This can include composites for construction, automotive parts, or even as a filler material. However, it's important to note that recycling fiberglass can be challenging due to its composite nature, and not all types of fiberglass are easily recyclable. Proper recycling facilities and methods are required to ensure the process is both effective and environmentally friendly.</p>

- Q: Is it possible to utilize black fiberglass tissue for crafting decorative items?

- <p>Yes, black fiberglass tissue can be used to create decorative elements. It is known for its strength, durability, and flexibility, making it an ideal material for various artistic and design applications. Fiberglass can be molded into different shapes and forms, and its black color can add a sleek, modern touch to any decor. It's often used in combination with other materials to create unique and eye-catching designs, from wall art to furniture accents. However, it's important to handle fiberglass with care due to its potential health risks and to ensure proper ventilation during any cutting or shaping processes.</p>

- Q: Is it possible to utilize black fiberglass tissue in the construction industry?

- <p>Yes, black fiberglass tissue, also known as black fiber-reinforced polymer (FRP), can be used in construction. It is valued for its high strength-to-weight ratio, corrosion resistance, and durability. Black fiberglass is often used in reinforcing concrete structures, as a component in composite materials, and for strengthening or repairing existing structures. It is also used in the creation of lightweight and strong building materials, such as rebar replacements and for cladding due to its resistance to harsh weather conditions.</p>

- Q: What is the standard thickness measurement for black fiberglass paper towels?

- <p>The thickness of black fiberglass paper towels can vary depending on the manufacturer and the specific product. Generally, these towels are known for their durability and thickness compared to standard paper towels. However, without a specific product reference, it's challenging to provide an exact measurement. Typically, they might range from 0.1 to 0.5 millimeters in thickness, but for precise information, one should refer to the product specifications or contact the manufacturer directly.</p>

- Q: The user is asking if they can use their old towels as a replacement for black fiberglass tissues.

- <p>While it might be tempting to repurpose old towels as a substitute for black fiberglass tissues, it's not advisable. Black fiberglass tissues are specifically designed for certain applications due to their unique properties, such as heat resistance and strength. Old towels, even if they are black, lack these specific characteristics and may not provide the same level of performance or safety. It's best to use materials as intended to ensure effectiveness and avoid potential issues.</p>

- Q: What is the tensile strength of black fiberglass paper, measured in terms of force per unit area?

- <p>The tensile strength of black fiberglass paper can vary depending on the specific type and manufacturer. Generally, it is known to have a tensile strength ranging from 100 to 200 MPa (megapascals). This high tensile strength makes it suitable for applications requiring durability and resistance to tearing, such as in electrical insulation and reinforcement in composite materials. It's important to check the specific product specifications for precise tensile strength values.</p>

- Q: This question asks about the various types of black fiberglass tissue that can be found in the market.

- <p>There are several types of black fiberglass tissue available in the market, each with distinct properties and applications. These include woven roving, chopped strand mat, continuous filament mat, surfacing mat, and stitch-bonded mat. Woven roving is used for high strength applications, chopped strand mat for general reinforcement, continuous filament mat for smooth surfaces, surfacing mat for providing a smooth finish, and stitch-bonded mat for added dimensional stability. Each type varies in weave, density, and fiber length, catering to different industrial needs.</p>

- Q: This question asks about the environmental effects of utilizing black fiberglass tissue.

- <p>The use of black fiberglass tissue can have several environmental impacts. It is often used in construction and insulation, which can reduce energy consumption and lower greenhouse gas emissions. However, the production process can be energy-intensive and may release pollutants. Additionally, black fiberglass tissue can contribute to urban heat island effect due to its dark color, which absorbs more heat. Proper disposal is crucial as improper disposal can lead to environmental contamination. Overall, while it has benefits in insulation, the environmental impact must be managed through sustainable production and disposal practices.</p>

- Q: Is it possible to use black fiberglass tissue as an insulating material for walls in residential buildings?

- <p>Yes, black fiberglass tissue can be used for wall insulation in residential homes. It is a common insulating material known for its thermal and acoustic insulation properties. Black fiberglass is a type of glass wool that is treated with a black pigment to improve its UV resistance and durability. It is effective in reducing heat transfer and can help in maintaining a comfortable indoor temperature. However, it is important to ensure that it is installed correctly and safely, as fiberglass can cause skin and respiratory irritation if not handled properly.</p>

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Aluminum

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords