Fiberglass Facing E-Glass Emulsion Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Fiber E-glass Emulsion Chopped Strand Mat

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

1. Uniform density ensures consistent fiberglass content and mechanical properties of the composites products.

2. Uniform powder distribution ensures good mat integrity, little loose fibers and small roll diameter.

3. Excellent flexibility ensures good mold ability with no spring back at sharp angles.

4. Fast and consistent wet-out speed in resins and rapid air lease reduce resin consumption and production cost and enhances productivity and mechanical properties of the end products.

5. The composite products have high dry and wet tensile strength and good transparency.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

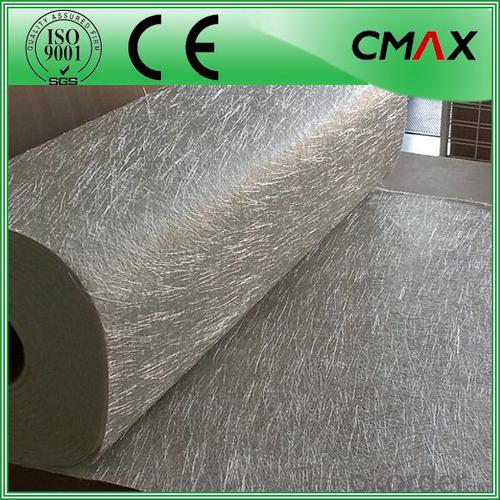

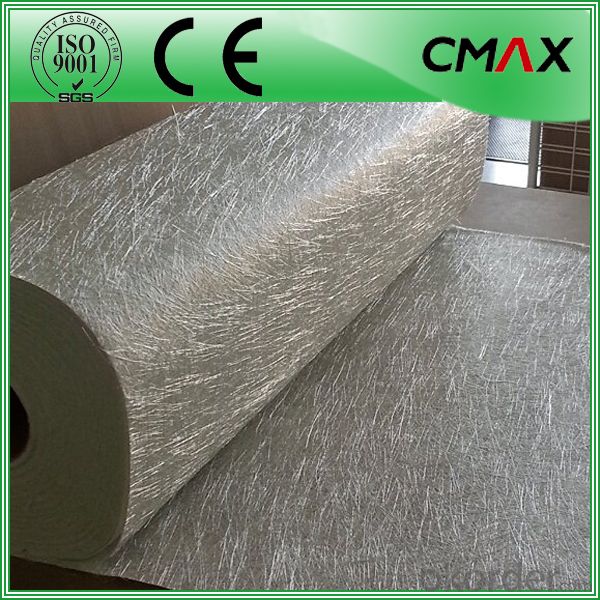

Products Shows:

Certificates:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton.

- Q: Is it possible to utilize recycled black fiberglass tissue for a future project?

- <p>Yes, you can use recycled black fiberglass tissue in your next project, provided it meets the quality and safety standards required for your specific application. Recycled fiberglass can be a sustainable and cost-effective alternative to new materials. Ensure that the recycled material has been properly processed to remove any contaminants and is free from degradation that could compromise its structural integrity. Always check with the supplier or manufacturer for any specific guidelines or certifications regarding the use of recycled materials in your project to ensure compliance with industry standards and safety regulations.</p>

- Q: This question asks for methods to clean and maintain a piece of black fiberglass tape to ensure its longevity and functionality.

- <p>To clean and maintain a piece of black fiberglass tape, first, remove any loose dirt or debris with a soft brush. Avoid using abrasive materials that could scratch the surface. For stubborn dirt, use a mild soap solution and a soft cloth to gently clean the tape. Rinse thoroughly with clean water and allow it to dry completely. To prevent dirt buildup, regularly wipe the tape with a dry cloth. Store the tape in a cool, dry place away from direct sunlight to prevent fading and degradation. Avoid using harsh chemicals or solvents as they can damage the tape. Regular inspection for any signs of wear or damage is also recommended to ensure the tape remains in good condition.</p>

- Q: Is it possible to use black fiberglass tissue as an alternative to regular paper tissues?

- <p>Black fiberglass tissue is not a suitable substitute for paper tissues. Fiberglass is a type of glass wool that is used for insulation and other industrial applications. It is not designed for personal use, especially not in contact with the skin or for cleaning purposes. Using fiberglass tissue could cause skin irritation, respiratory issues, and other health problems. Paper tissues are specifically designed for personal use, providing a soft and safe material for everyday needs.</p>

- Q: Is it possible to use black fiberglass tissue in the manufacturing of furniture?

- <p>Yes, black fiberglass tissue can be used for furniture manufacturing. It is known for its strength, durability, and resistance to various environmental conditions, making it suitable for creating sturdy and long-lasting furniture. Fiberglass is often used in outdoor furniture and certain types of modern indoor furniture due to its versatility and ability to be molded into various shapes. However, it's important to consider the aesthetic appeal and the specific requirements of the furniture design when choosing to use black fiberglass tissue.</p>

- Q: Is it possible to utilize black fiberglass tape for fixing a leaking faucet or pipe?

- <p>While black fiberglass tape can be used to repair minor leaks in pipes, it is not typically recommended for fixing leaky faucets. For pipes, especially plastic ones, fiberglass tape can create a temporary seal. However, for faucets, plumber's tape (Teflon tape) is more suitable as it is designed to handle the threads and tight seals required in faucet connections. Always remember that for long-term solutions or significant leaks, professional repair or replacement is advisable.</p>

- Q: This question asks for methods to effectively clean and maintain black fiberglass flooring to keep it in good condition.

- <p>To effectively clean and maintain your black fiberglass flooring system, follow these steps: 1. Regularly sweep or vacuum the floor to remove dust and debris. 2. For stains or spills, use a mild detergent mixed with warm water and a soft cloth or mop. Avoid using harsh chemicals or abrasive cleaners as they can damage the surface. 3. Rinse the floor with clean water to remove any soap residue. 4. Dry the floor promptly to prevent water damage. 5. Periodically inspect the floor for any signs of wear or damage and address them promptly. 6. Apply a protective coating or sealant as recommended by the manufacturer to maintain the floor's appearance and durability. Always refer to the manufacturer's guidelines for specific care instructions.</p>

- Q: This question asks for the primary application of black fiberglass tissue.

- <p>The main use of black fiberglass tissue is in the reinforcement of composite materials, particularly in the manufacturing of reinforced plastics and thermosetting resins. It is used in the production of various products such as automotive parts, electrical insulation, and construction materials due to its high strength, heat resistance, and chemical stability. Additionally, black fiberglass tissue is valued for its non-conductive and non-magnetic properties, making it suitable for applications where these characteristics are essential.</p>

- Q: What are the uses of black fiberglass tissue in the construction industry?

- <p>Black fiberglass tissue, also known as black glass fiber cloth, is widely used in construction for its heat resistance, strength, and durability. It is commonly used as a reinforcement material in cementitious materials, such as in the production of GRC (Glass Reinforced Concrete) panels and other composite materials. It can also be used as a fire-resistant barrier in walls and ceilings, and for insulation purposes. Additionally, it is employed in the creation of lightweight and strong structures, such as in the construction of roofs and facades, due to its high tensile strength and low weight.</p>

- Q: Can fiberglass facing be painted or customized?

- Yes, fiberglass facing can be painted or customized. Fiberglass is a versatile material that can be easily painted using various types of paint, such as acrylic or oil-based paint. Before painting, it is important to properly prepare the surface by cleaning it and removing any dirt or debris. Additionally, it is recommended to use a primer to improve adhesion and ensure a smooth finish. Once the primer is dry, you can apply the desired paint color or customize the fiberglass facing using stencils, decals, or other decorative techniques. However, it is essential to use paint and materials that are suitable for outdoor use if the fiberglass facing will be exposed to harsh weather conditions. Overall, with the right preparation and paint, fiberglass facing can be painted or customized to meet your specific aesthetic preferences or design requirements.

- Q: Can fiberglass facing be used in both residential and commercial buildings?

- Fiberglass facing is applicable for use in both residential and commercial buildings. This versatile material offers numerous advantages, including thermal insulation, moisture resistance, and soundproofing. Its diverse properties make it suitable for various applications in both residential and commercial settings. In residential buildings, fiberglass facing can be utilized in insulation products for walls, ceilings, and attics. By doing so, it contributes to the enhancement of energy efficiency and reduction of heating and cooling expenses. Furthermore, it can be integrated into residential HVAC systems to improve air quality and minimize noise transmission. Similarly, in commercial buildings, fiberglass facing can be incorporated into insulation products for walls, roofs, and HVAC ductwork, providing the same benefits as in residential settings. Moreover, it can be utilized in commercial acoustic panels and soundproofing systems to diminish noise levels in offices, conference rooms, and other commercial spaces. Overall, fiberglass facing is an adaptable material that effectively enhances insulation, moisture resistance, and soundproofing properties in both residential and commercial buildings.

Send your message to us

Fiberglass Facing E-Glass Emulsion Chopped Strand Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords