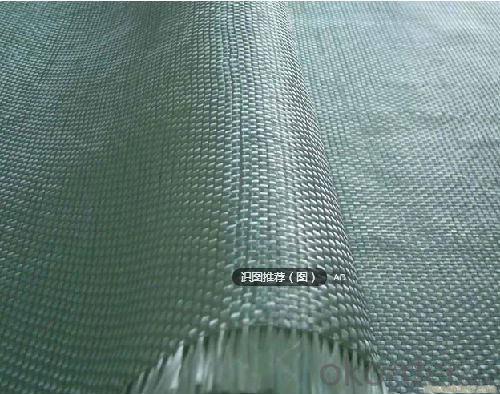

Fiberglass Roofing Fabric with Medium Silica Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction:

Medium silica fabrics can be used for a long period of time without changing their properties perat the temperature of 800℃ as it contains more than 70%±5% silica.

2.Properties

No asbestos orceramic,no harm to human

Low thermal conductivity,excellent thermal insulation

Superb electric insulation

Inert to majority of chemical reagents

Good flexibility

3.Application

Fire fighting

High temperature gas filtration

Thermal insulation

4.Specification

| Type | Weave Type | Area Weight | Width cm | Thickness | Warp Yarns/cm | Weft yarns/cm |

| RS-600 | Satin 8HS | 600±50 | 100 | 0.75±0.1 | 18±1 | 13±1 |

| RS-1100 | Satin 12HS | 1100±50 | 100 | 1.35±0.1 | 18±1 | 13±1 |

5.Package and Delivery Time.

Packed with carton and pallets.The products will be ready in 15-20 days after the order confirmation.

FAQ:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: How does fiberglass fabric perform in flexibility?

- Known for its excellent flexibility, fiberglass fabric is a lightweight and pliable material that easily takes on various shapes and forms. This flexibility stems from the composition of fiberglass itself, which consists of thin glass fibers woven together. These fibers possess high flexibility, allowing them to bend and flex without any risk of breaking or compromising their structural integrity. Consequently, fiberglass fabric proves to be a versatile material suitable for a wide range of applications necessitating flexibility. Moreover, fiberglass fabric can also be combined with other materials to further enhance its flexibility. Overall, fiberglass fabric delivers exceptional performance in terms of flexibility, making it a favored choice in industries like automotive, aerospace, and construction.

- Q: How is fiberglass fabric used in the insulation industry?

- Fiberglass fabric is extensively used in the insulation industry due to its excellent thermal and acoustic insulation properties. It is commonly used as an insulating material in various applications such as residential and commercial buildings, automotive, aerospace, and industrial equipment. One of the primary uses of fiberglass fabric in insulation is in the construction industry. It is often installed in walls, floors, and ceilings to reduce heat transfer, thus improving energy efficiency and reducing heating and cooling costs. The fabric acts as a barrier, preventing the flow of heat between different areas of a building. Additionally, its ability to resist moisture absorption helps to prevent mold and mildew growth, ensuring a healthier indoor environment. Fiberglass fabric is also utilized in the insulation of pipes, ducts, and HVAC systems. It helps to maintain the desired temperature and prevent heat loss or gain during the transportation of liquids or air. This ensures efficient operation and reduces energy consumption. Furthermore, fiberglass fabric is employed in the insulation of vehicles and aircraft. It helps to minimize the transfer of heat and noise from the engine or outside environment, providing a comfortable and quiet interior for passengers. Its lightweight and flexible nature make it an ideal choice for these applications, as it can be easily molded and installed in complex shapes and tight spaces. In industrial settings, fiberglass fabric is used for insulation in equipment such as boilers, furnaces, ovens, and tanks. It helps to retain heat, ensuring efficient operation and minimizing energy loss. Additionally, fiberglass fabric is fire-resistant, which is crucial for industries that deal with high temperatures and potential fire hazards. Overall, fiberglass fabric's versatility, durability, and excellent insulating properties make it a widely used material in the insulation industry. Its ability to provide thermal and acoustic insulation, resist moisture, and withstand high temperatures make it a preferred choice for various applications, contributing to energy efficiency, environmental sustainability, and improved comfort.

- Q: Can fiberglass fabric be used for making backpacks?

- Yes, fiberglass fabric can be used for making backpacks. Fiberglass fabric is a strong and durable material that is known for its resistance to heat, chemicals, and abrasion. It is also lightweight and has good tensile strength, making it suitable for backpacks. Additionally, fiberglass fabric is often used in industries such as aerospace, automotive, and marine due to its high strength-to-weight ratio. However, it is important to note that fiberglass fabric can be rigid and stiff, which may affect the overall comfort and flexibility of the backpack. Therefore, it is essential to consider the specific requirements and preferences of the backpack user before using fiberglass fabric for making backpacks.

- Q: How does fiberglass fabric perform in vibration isolation applications?

- Fiberglass fabric is commonly used in vibration isolation applications due to its excellent performance in this regard. The fabric's inherent properties, such as high tensile strength, flexibility, and low thermal conductivity, make it an ideal material for effectively isolating vibrations. When subjected to vibrations, fiberglass fabric absorbs and dampens the energy generated, thereby reducing the transfer of vibrations from one component to another. This ability to absorb vibrations is crucial in various industries, including automotive, aerospace, and construction, where minimizing vibrations is essential for optimal performance and safety. Additionally, fiberglass fabric's high tensile strength ensures that it can withstand the forces and stresses associated with vibrations without tearing or breaking. This strength is important for maintaining the fabric's integrity and effectiveness as a vibration isolator, as any damage to the fabric could compromise its performance. Furthermore, the flexibility of fiberglass fabric allows it to conform to different shapes and surfaces, ensuring a secure and tight fit in vibration isolation applications. This flexibility enables the fabric to effectively isolate vibrations across a wide range of frequencies and amplitudes, making it a versatile solution for various vibration control needs. Lastly, fiberglass fabric's low thermal conductivity is advantageous in vibration isolation applications where temperature differentials exist. By minimizing heat transfer, the fabric helps maintain the stability and performance of the isolated components, especially in environments with extreme temperatures. In summary, fiberglass fabric performs exceptionally well in vibration isolation applications due to its ability to absorb and dampen vibrations, high tensile strength, flexibility, and low thermal conductivity. Its effectiveness, versatility, and durability make it a preferred choice for industries requiring efficient vibration control.

- Q: Waterproof method of glass fiber cloth for toilet

- The pipe is worn through the root of the floor to strengthen the water.

- Q: What are the different roll lengths available for fiberglass fabric?

- Fiberglass fabric comes in different roll lengths, which depend on the manufacturer and the intended use. Typically, the most common roll lengths for fiberglass fabric range from 50 to 100 yards. However, it's worth mentioning that certain manufacturers may provide custom roll lengths to accommodate specific project requirements. These custom lengths can greatly vary, with shorter rolls suitable for small-scale projects and longer rolls suitable for larger industrial applications. To ensure that you get the right fiberglass fabric roll length for your needs, it is advisable to consult the manufacturer or supplier regarding the available options.

- Q: Can fiberglass fabric be used for reinforcement in underground storage tanks?

- Yes, fiberglass fabric can be used for reinforcement in underground storage tanks. Its high strength, corrosion resistance, and durability make it a suitable material for reinforcing the structure of underground storage tanks, ensuring their structural integrity and preventing leaks or failures.

- Q: Can fiberglass fabric be used for insulation in HVAC ducts?

- Yes, fiberglass fabric can be used for insulation in HVAC ducts. It is a common choice due to its excellent thermal insulation properties, fire resistance, and ability to withstand high temperatures. It helps to prevent heat loss or gain in ductwork, improving energy efficiency and maintaining desired indoor temperatures.

- Q: What are the different types of fiberglass fabrics available?

- There are several types of fiberglass fabrics available, including plain weave, twill weave, satin weave, and unidirectional fabrics.

- Q: What are the different weaving patterns available for fiberglass fabric?

- There are several different weaving patterns available for fiberglass fabric, each with its own unique characteristics and applications. 1. Plain Weave: This is the most basic and commonly used weaving pattern for fiberglass fabric. It consists of a simple over-and-under interlacing of warp and weft yarns, creating a balanced and uniform fabric structure. Plain weave fiberglass fabric offers good strength, dimensional stability, and is suitable for a wide range of applications. 2. Twill Weave: Twill weave creates a diagonal pattern on the fabric surface, achieved by passing the weft yarn over multiple warp yarns before going under. This weaving pattern enhances the fabric's drapability, flexibility, and allows for better conformability to complex shapes. Twill weave fiberglass fabric is often used in applications where flexibility and durability are required, such as in the aerospace and automotive industries. 3. Satin Weave: Satin weave is characterized by long floats, where the weft yarn passes over multiple warp yarns before going under. This creates a smooth and lustrous surface with less crimp and higher yarn density. Satin weave fiberglass fabric offers excellent drapeability, high strength-to-weight ratio, and is commonly used in applications that require a high-quality surface finish, such as marine and sporting goods industries. 4. Leno Weave: Leno weave is a unique pattern where the warp yarns are twisted around each other, creating an open and flexible structure. This weaving pattern enhances the fabric's breathability and allows for better resin impregnation during composite fabrication. Leno weave fiberglass fabric is often used in applications such as filtration, reinforcement in composites, and as a base fabric for laminates. 5. Jacquard Weave: Jacquard weave is a complex pattern created by individually controlling each warp yarn. This weaving technique allows for intricate designs, patterns, and textures to be woven into the fabric. Although less common in fiberglass fabric, jacquard weave can be used to create custom designs or specific functional features in specialized applications. Overall, the choice of weaving pattern for fiberglass fabric depends on the desired properties, performance requirements, and intended applications. Each weaving pattern offers unique characteristics and advantages, allowing for a wide range of possibilities in utilizing fiberglass fabric across various industries.

Send your message to us

Fiberglass Roofing Fabric with Medium Silica Fiberglass Fabrics

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords