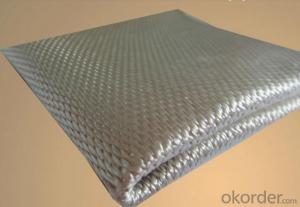

Fiberglass Fabrics Treated with Vermiculite

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Supply high temperature proof of texturized fiberglass yarn, tape, cloth, rope,fabrics with rubber coated, fiberglass Fabric Treated with Vermiculite.

(2)Fiberglass fabrics with silicone rubber coated:

Rubber coating fiberglass cloth is a fiberglass cloth, which possesses the properties of temperature resistance, anti-corrosion, high strength and made by rolling or impregnation with organic rubber. It is a newly made product with properties and many uses.

(3)high temperature proof fiberglass fabric like 3732 and 7628,HT800

It has: plain weave, twill weave, satin weave, gauze weave.

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines. Such as EW140, EW7628. 3732,

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth, such as EW3732, EW3784.

c) Satin weave: compared with plain weave and twill weave, it is of high density,high intensity, with a soft and loose structural weave with a good texture. It is applicable for use as a higher reinforced material in machinery, such as EW3784,EW3788.

d).Gauze weave: said lattice twist weave. It can be used in spread model curtain,resin reinforced emery wheel gray cloth and lattice embed belt.

Supply high temperature proof of fiberglass Fabric Treated with Vermiculite,,

- Q: Two, fat and PVC paste resin paste into the sizing, coated on glass fiber cloth, so that after baking, how do not shrink?

- Do not grind finer, the particles are too small at room temperature, often because of excessive solvent and paste viscosity high.

- Q: Can fiberglass fabric be used for geotextiles?

- Yes, fiberglass fabric can be used for geotextiles.

- Q: Can fiberglass fabric be used for insulation in pipelines?

- Yes, fiberglass fabric can be used for insulation in pipelines. Fiberglass fabric is known for its excellent thermal insulation properties and is commonly used in various industrial applications, including pipeline insulation. It is an effective material for reducing heat loss or gain in pipelines and helps maintain the desired temperature of the transported fluid. Fiberglass fabric is lightweight, flexible, and easy to install, making it an ideal choice for insulating pipelines. Additionally, it is resistant to corrosion, moisture, and chemical exposure, ensuring long-term insulation performance.

- Q: How is fiberglass fabric cleaned and maintained?

- Fiberglass fabric can be cleaned and maintained with a few simple steps. First, it is important to remove any loose dirt or debris from the fabric by gently brushing or vacuuming it. This will prevent any particles from becoming embedded in the fabric during the cleaning process. Next, prepare a cleaning solution by mixing mild detergent or soap with warm water. Avoid using harsh chemicals or bleach, as they can damage the fabric. Dip a soft cloth or sponge into the cleaning solution and gently scrub the fiberglass fabric. Be careful not to apply too much pressure, as this can cause the fabric to stretch or tear. After scrubbing, rinse the fabric thoroughly with clean water to remove any soap residue. It is important to remove all traces of detergent to prevent it from attracting dirt in the future. Once rinsed, allow the fabric to air dry completely. Avoid using a dryer or direct sunlight, as they can cause shrinkage or fading. To maintain the cleanliness of the fiberglass fabric, it is recommended to regularly brush or vacuum it to remove any surface dirt. Additionally, it is advisable to store the fabric in a clean and dry place when not in use, as this will help prevent the accumulation of dust or debris. By following these simple cleaning and maintenance steps, fiberglass fabric can remain in good condition and last for a long time.

- Q: Can fiberglass fabrics be used for insulation in industrial machinery?

- Fiberglass fabrics are indeed applicable for insulating industrial machinery. Their remarkable thermal insulation properties stem from their low thermal conductivity. They possess a strong resistance to heat transfer, rendering them an appropriate selection for insulating industrial machinery that functions under high temperatures. Moreover, fiberglass fabrics are non-flammable and exhibit commendable resistance to chemicals, ensuring a secure and enduring choice for insulation in industrial environments. They proficiently capture heat and prevent energy dissipation, thereby enhancing the overall efficiency and performance of the machinery. All in all, fiberglass fabrics prove to be a dependable and efficient alternative for insulating industrial machinery.

- Q: What kind of fiberglass fabric and asphalt paint do you use for 5mm thick fiberglass?

- Glass cloth and asphalt paint are not called GRP

- Q: How is fiberglass fabric used in insulation?

- Fiberglass fabric is a widely used material for insulation due to its exceptional thermal properties. It finds application primarily in two forms: batts and loose-fill insulation. When it comes to fiberglass batts, the fabric is woven into sheets, which are then tailored to fit snugly between the studs, joists, and beams of buildings. These batts are commonly installed in walls, ceilings, and floors to provide an effective shield against heat transfer. The fiberglass fabric works by capturing air within its fibers, forming pockets of still air that greatly diminish the conduction of heat. This process, known as thermal insulation, helps to maintain a pleasant indoor temperature and reduce energy consumption by minimizing the need for heating and cooling. Another way fiberglass fabric is employed in insulation is through loose-fill insulation. In this form, the fabric is processed into fine fibers and blown or poured into enclosed spaces such as walls and attics. The fabric fibers intertwine, creating a dense layer that acts as a thermal barrier. Loose-fill insulation is particularly efficient in filling irregularly shaped or hard-to-reach spaces, ensuring that there are no gaps or voids that could allow heat to escape or enter the building. Fiberglass fabric is also often combined with other materials to enhance insulation performance. For instance, it is frequently blended with foam or foil to produce rigid panels or reflective insulation. These composite materials provide additional advantages such as moisture resistance, soundproofing, and improved thermal resistance. To sum up, fiberglass fabric is utilized in insulation to minimize heat transfer, enhance energy efficiency, and establish a comfortable indoor environment. Whether in the form of batts or loose-fill, fiberglass fabric acts as a thermal barrier, reducing the conduction of heat and augmenting the insulation properties of buildings.

- Q: How do fiberglass fabrics perform in terms of heat resistance?

- Fiberglass fabrics have excellent heat resistance properties. They can withstand high temperatures without melting or losing their structural integrity. This makes them suitable for various applications where heat protection is required, such as insulation materials, fireproof clothing, and thermal barriers.

- Q: Is fiberglass fabric resistant to insects?

- Yes, fiberglass fabric is generally resistant to insects.

- Q: Is fiberglass fabric resistant to aging or deterioration?

- Fiberglass fabric exhibits remarkable resistance to aging or deterioration. It is a man-made material composed of delicate glass fibers skillfully interwoven to create a textile. These fibers possess extraordinary durability and do not easily deteriorate with the passage of time. They are impervious to UV rays, moisture, chemicals, and fluctuations in temperature, rendering them ideal for a multitude of applications where longevity is of utmost importance, such as insulation, construction, and the marine industry. Moreover, fiberglass fabric is renowned for its exceptional tensile strength, dimensional stability, and fire resistance, thereby further fortifying its resistance to aging or deterioration. All in all, fiberglass fabric is an exceptionally dependable and enduring material capable of enduring the test of time.

Send your message to us

Fiberglass Fabrics Treated with Vermiculite

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords