Feutre Geotextile PP (Polypropylene) Non Woven with Short Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Non Woven Geotextile with Short Fiber Needle Punched, Find Details about Non Woven Geotextile with Short Fiber Needle Punched and Make an Inquiry for Geotextile at OKorder.com.

Geotextile Specifications:

Geotextile fabrics

Material:polypropylene fibric

Width:1-9m

Colour:white or black

Use:road ,highway,filter,etc

Weight:100-1500g/m2

Gextextile Description:

--Our geotextile can be made of polypropylene (PP) or polyester (PET) .

-- The weight is available from 100g/m2 to 1500g/m2 and the width from 1m to 8m,

-- Two kinds of processing technical to select: needle punched and thermally bonded, long fiber or short fiber.

-- All kinds of colors are available.

It is widely known as earthwork material and industry fabric, used in the areas of railway, highway, water conservancy, dam, tunnel, subway, environment protection and so on.

-- We can supply different specifications as customers’ request.

Geotextile Specification:

Material: polypropylene (PP) thermally bounded

Weight: 100g/m2-1500g/m2

Width: 1-9m

Length: As customers’ demand (usually is 100m)

Package: PE film and woven cloth

Delivery time: With in 3weeks after received the advance payment

Application of Geotextile:

1. Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2. Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3. Reinforcement

The highway, railway, soilstone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4. Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

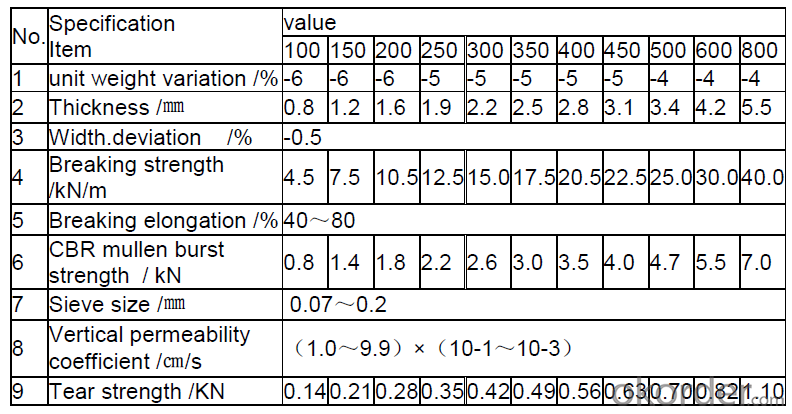

Technical specification of short fiber needle punched non-woven geotextiles:

According to GB/T17638-1998 Standard

Geotextile Specification

Geotextile Show:

Geotextile Show:

RFQ:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

If you want to find more details about the non-woven geotextile, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What are the key differences between woven and nonwoven geotextiles?

- The key differences between woven and nonwoven geotextiles lie in their manufacturing processes and physical properties. Woven geotextiles are created by interlacing individual yarns or fibers in a crisscross pattern, resulting in a stable and strong fabric. On the other hand, nonwoven geotextiles are manufactured by bonding or felting fibers together using mechanical, thermal, or chemical processes, resulting in a fabric with random fiber orientation. Woven geotextiles typically have higher tensile strength and puncture resistance due to their interlocked yarns, making them suitable for applications that require structural stability and load distribution. They are commonly used in road construction, erosion control, and soil stabilization projects. Nonwoven geotextiles, while generally having lower strength properties compared to their woven counterparts, offer advantages such as filtration, drainage, and separation functions. They are commonly used for filtration and separation in drainage systems, as well as in erosion control, landscape fabric, and geocomposite applications. Overall, the choice between woven and nonwoven geotextiles depends on the specific project requirements, such as load-bearing capacity, filtration needs, and budget considerations.

- Q: Are geotextiles suitable for use in underground drainage systems?

- Yes, geotextiles are suitable for use in underground drainage systems. Geotextiles are permeable fabrics that can be used to separate, filter, reinforce, and drain soil in a drainage system. They help prevent the clogging of pipes and provide additional stability and longevity to the overall system.

- Q: Can geotextiles be used in the protection of bridge abutments?

- Yes, geotextiles can be used in the protection of bridge abutments. Geotextiles are commonly used in civil engineering projects to provide erosion control, soil stabilization, and filtration. When applied to bridge abutments, geotextiles help to prevent soil erosion, reduce water infiltration, and enhance the overall stability and durability of the structure.

- Q: How do geotextiles help with filtration in geosynthetic clay liners?

- Geotextiles play a crucial role in enhancing filtration in geosynthetic clay liners (GCLs) by acting as a barrier that prevents fine particles from migrating into the clay layer. The geotextile acts as a filtration medium, allowing water to pass through while retaining the soil particles. This helps to maintain the integrity and effectiveness of the GCL by preventing clogging and maintaining the desired hydraulic conductivity.

- Q: Are geotextiles poisonous?

- Geotextile is not toxic, the production of geotextile raw materials are polyester (PET) or polypropylene (PP). Polyester and polypropylene have become daily necessities. Many of the mineral water bottles are also produced by PET and PP raw materials.

- Q: How do geotextiles contribute to environmental sustainability?

- Geotextiles contribute to environmental sustainability by providing erosion control, improving soil stability, and promoting vegetation growth. They help prevent soil erosion by acting as a barrier against the forces of wind and water, reducing the sedimentation of water bodies and preserving the quality of nearby ecosystems. Geotextiles also enhance soil stability by reinforcing weak soils, reducing the need for extensive excavation or replacement. Moreover, they facilitate the establishment of vegetation, promoting biodiversity and restoring natural habitats. Overall, geotextiles play a crucial role in mitigating environmental degradation and supporting sustainable land management practices.

- Q: How do geotextiles reduce hydraulic pressure in soil?

- Geotextiles reduce hydraulic pressure in soil by allowing water to flow through them, thereby acting as a drainage layer. This helps to prevent the build-up of water pressure within the soil, which can lead to soil erosion and instability.

- Q: How do geotextiles aid in the reduction of soil compaction?

- Geotextiles aid in the reduction of soil compaction by providing a layer of material that distributes the load more evenly, reducing the pressure on the soil. This helps to improve soil structure, increase porosity, and enhance drainage, ultimately preventing soil compaction.

- Q: 3923.1 why not apply to geotextiles

- Geotextile price, geomembrane price, composite geomembrane price can be found tgcl1123 to see

- Q: Can geotextiles be used in the construction of artificial islands?

- Yes, geotextiles can be used in the construction of artificial islands. Geotextiles are often used as a reinforcement material to enhance the stability of soil and prevent erosion. In the context of artificial island construction, geotextiles can be used to strengthen the foundation, provide stability to the soil, and protect against wave action.

Send your message to us

Feutre Geotextile PP (Polypropylene) Non Woven with Short Fiber

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords