FeSi 72%&75% With Chinese Origin Export

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

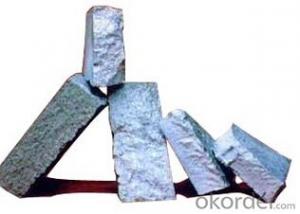

Ferro Silicon 72% & 75%.It is used extensively in the steel-making, casting non-ferrous metals and other industrial production.I

1, Features:

The appearance of Ferro Silicon is the grey lumpish solid. It has very strong stabilities and does not place any chemical reaction in the dry air.

2, Application:

It is used extensively in the steel-making, casting non-ferrous metals and other industrial production.It is the good deoxidizer and most steel kind use the Ferro Silicon for deoxidization;

In steel smelting, it is used to sedimentary accretion and expanding deoxidizing.It is used to prove the strength, hardness and elasticity of steel greatly in steel casting.

Grade | Chemicals Composition(%) | ||||

Si | Al | C | S | P | |

%(min) | %(max) | ||||

FeSi 75% FeSi 75% FeSi 72% | 75 | 0.5-1.0 | 0.15 | 0.02 | 0.04 |

75 | 1.5-2.0 | 0.20 | 0.02 | 0.04 | |

72 | 1.5-2.0 | 0.20 | 0.02 | 0.04 | |

FeSi 70% | 70 | 1.5-2.0 | 0.20 | 0.02 | 0.04 |

Lump size | 10-50 mm, 50-100 mm,10-100 mm, 50-150mm: 90%min, or at customer’s option; | ||||

Packing | In jumbo bag about 1MT/bag | ||||

FACTORY:

- Q: In addition, the same furnace products out, the standard sample bar is qualified, no hole, but YT14 blade has more holes, why is that ah?

- YT14 Feiyan containing titanium, titanium with high oxygen affinity, if high oxygen content and sintering process not reasonable, high temperature gas production could not be drained to form holes, you see the sintering process is reasonable, the presence of liquid phase before the vacuum degree is not high enough. In addition, such as incomplete degassing holes in the product, the edge is more.

- Q: What type of carbide for punching dies? Better. Where can I buy it?

- Overall, Zhuzhou cemented carbide works, Shanghai alloy materials factory, Zigong cemented carbide plant, new carbide knives are good. But the single pair of milling cutters is not clear! There is no YL!

- Q: Can hard alloy be welded with silver electrode?

- Hard alloy can use silver electrode welding, some more liquid silver wire than general tin brass or iron brass, the cost is too high, the strength level than the ordinary copper electrode should be higher, personal suggestions for the selection of copper base up instead of silver electrode, such as the WEWELDING 46 electrode (referred to as Odin Wei 46 If the strength of electrodes), the structure is higher than silver, if it is to achieve the high permeability, it is still the ideal to silver, only from the strength level, is not WEWELDING 46 copper based electrode.

- Q: What is hard alloy steel?

- Modern ultra hard alloys are produced by sintering of carbides of tungsten carbide and some other elements. It is the hard metal (tungsten, tantalum, titanium, molybdenum, etc.) carbide carbide particles, with one or several iron elements (cobalt, nickel or iron) powder mixed, pressed molding, and then made by sintering.

- Q: Machining center 8 mm carbide cutter processing 45 steel, how to set the speed, feed, and moving speed?

- if the speed in the three thousand, each Z axis 0.3 wire feed, can be a little faster, must spiral knife Oh, this is not a knife eat 5 mm. I found a 55 degree flat cutting parameters of tungsten steel milling table

- Q: Carbide coated drill bit will reduce the service life after grinding, how to avoid?

- Hello, there is no way to avoid the problem of reducing the service life of the carbide coated drill bit after grinding;Cemented carbide bit, in its use, the surface coating, the blade has already been damaged, can not reach the integrity of the factory, so that it affects the service life of the drill bit,There is a need to be re grinding, coating, the coating has physical and chemical coating and coating, coating chemical now use more chemical coating basically is the tool coating at high temperature, so the temperature can cause 2 damage of cemented carbide substrate;So it also affects the service life;The effect of bit life, the most important is the geometric design of drill bit; before the design is not good, but when re grinding and grinding a good point, sometimes improve the service life, but the original drill must use will reduce the life of the;About those problems mentioned above, in fact, that is, some methods to improve the service life of the drill, upstairs can refer to

- Q: In addition to diamonds, Hunan there are no good carbide manufacturers? Product advantages in the ordinary blade, knife head and mining tools. Which factory's alloy is of good quality? The best size, with the original tungsten powder. Please know what to say, first thank you

- Zhuzhou China Tungsten Alloy Co., the company's main products are: sand making machine alloy strip, mining carbide tools, hard alloy, hard alloy, hard alloy mould plate, carbide blade, cutter, hard alloy, etc. at the same time or special "diamond" brand hard alloy cutter dealer. The company uses one to one service, reasonable price, cost-effective, prompt delivery, heavy credit, Shou contract, guarantee product quality and other thoughtful service, so that you can rest assured.

- Q: How to solve the severe wear of the flank of the carbide blade during machining?

- 2. Contact the company or log on to the company's website for communication.Carbide inserts are made of hard alloy, an alloy made from refractory metals, hard compounds, and bonded metals by powder metallurgy.Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.

- Q: The difference between HSS and carbide knives

- High speed steel which is mainly used in the rapid operation of the machine, its good fatigue performance, high temperature performance is better, but the hardness is generally hard alloy steel mainly refers to alloy steel with high hardness, high hardness of the steel is mainly emphasized in a certain range, but may be brittle or will be relatively large, high performance high temperature, poor.

- Q: Printing requirements for cemented carbide

- Its disadvantages are: there are a small amount of pores and defects in the product, and the carbon content of the sinter will decrease.Hot isostatic pressing sintering in sintering with inert gas, liquid metal or solid particles as pressure transfer medium in each direction of the sintered body exert equal pressure, not even this can overcome ordinary hot pressing pressure is not uniform and the resulting product performance. The hot isostatic pressing of cemented carbide can eliminate the pores in the alloy and the drilling pool after sintering, and restrain the growth of WC grain. The Kennametal Inc installed the first heating chamber for 277mm * 1270mm in 1967. The temperature is up to 1500oC and the pressure can reach140MPa's hot isostatic pressing machine has taken the lead in successfully applying the technology of hot isostatic pressing to the production of cemented carbide. Since then, hot isostatic pressing technology has developed rapidly in foreign countries (especially in the United States).

Send your message to us

FeSi 72%&75% With Chinese Origin Export

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords