High-Quality Ferro Silicon Raw Materials for Refractory Applications in South Korea

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ferro Silicon

Usage

Ferro silicon is widely used in the steel making,iron casting ,low-carbon ferroalloy producing:

1 In the steel making field,Ferro silicon is used as deoxidizer and alloying agent to precipit and diffusedeoxidation.Adding a certain amount silicon of fe-si to the steel can obviously improve the strength ,hardness ,elasticity and permeability of steel.

2 In the iron casting,it is used as ball mile agent and alloying agent especially in the nodular iron casting, Adding ferrosilicon to cast iron ,it can prevent the formation of carbide and promote the precipitation of graphite and the nodulizing.then the mechanical capacity can be the same of steel's.

3 High-silicon ferrosilicon can be used for the production of the low-carbon reductant in ferro alloy industry.

4 In addition ,ferro silicon powder can be used as a suspended phase in the mineral processing industry and coatings for welding electrodes in the electrode manufactruing.

Application

Used as deoxidants and desulfurizing agents, and could purity the molten steel, etc. The size includes:0-3mm, 3-25mm,10-50mm, etc.

Packaging & Delivery

Packing Details: In 1 MT Jumbo Bags

Delivery Detai | Within 30 days after received the deposite |

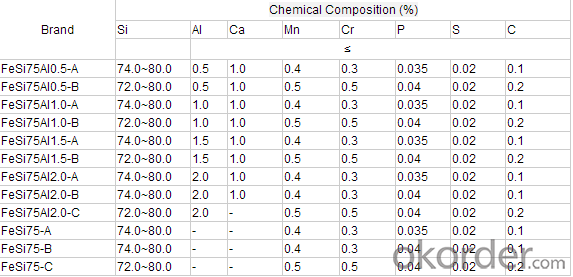

Specification

- Q: What's the fire endurance of fire windows?

- Fire endurance of fire doors and fire windows stipulated by the fire prevention norm: Fire endurance of A class fire door or fire window is 1.2h rather than 1.5h, and fire endurance of B class fire door or fire window is 0.9h rather than 1.0h. Fire prevention code doesn't explicitly state that the fire door has thermal insulation function, so it can definitely be interpreted that the fire door only has fire integrity. For the fire door without heat-shielding performance, at certain distance from the unexposed surface, it has strong thermal radiation and is easy to hurt people. For the A class thermal insulating fire door, its fire integrity is 0.1h shorter than that of the corresponding fire door stipulated in the specification, but its heat-shielding performance and integrality is improved. All in all, compared with the specification that the fire integrity of the A class fire door should be 0.6h, it has much more improved its performance.

- Q: What characteristics do A grade external wall fireproofing material have?

- For characteristics of A grade external wall fireproofing material, its main raw material uses cold resistant and thermal insulated, environmental protection and energy saving material with good insulation, keeping the indoor temperature steady and making the environment more comfortable. It is several times better than other masonry in overall strength and resist capability, and it can also hang heavy objects such as air conditioners by directly nailing or installing expansion bolts. Single point hanging machine can withstand heavy objects with the weight of more than 45kg. It can also be directly fixed to the tiles, wallpaper, wooden plaques, paint, etc.

- Q: which kind of material should be used in fireproofing cabinet?

- Natural stone,marble. advantage: Colorful, soft texure, natural and diverse texture, easy to cut or engraving molding. Disadvantages: Because it is a natural formation, tiny loose crackle is easily folded, because the stone is porous material structure, if sewage and waste water permeate in the structure in the process of production, transportation or construction, it's difficult to clean and easy to crack. In daily cleaning, it is inevitable that there will be some residue left, and dirt is filled into crack under the wiping of rag and becomes a breeding ground for bacteria. 2, granite. advantages: Granite has big density and high hardness, with wear-resistant surface, it's one of the most common materials for family decoration. Compared with natural marble, it can be used in the materials of kitchen countertops, and granite has good anti-bacterial regeneration ability. Disadvantages: As the cabinet table material, natural stone is usually not very long, so in order to produce a long overall table (especially U-shaped, L-type table), it will certainly exist joints, which are also easy to hide dirt. 3, artificial stone. advantages: Artificial stone has richful lines and colors, and it can be comparable to stone, it's non-toxic, non-radioactive, easy to clean, and can be truly seamless splicing. it belongs to economic environmentally friendly material. Disadvantages: Artificial stone belongs to the processing industry, and has low technology requirements, The inferior products of many small companys are fulled in the market and damage customers' interests. There exist faded color,poor aging resistance,oil stain and other issues in affordable products.

- Q: Which refractory quality inspection authority is good?

- Download refractory quality inspection LIRR in Henan is nationally recognized. Of course, it is an authority, but the cost is very high.

- Q: What defect does fused cast refractories have ?

- What defect doesfusion-cast refractory material have ? In glass production, in addition to refractory as a building material and consider its durability, we still must attach great importance to its influence on glass quality. In such cases, the impact on the quality of glass is mainly the defects that eroded down refractory materials mixed in the glass, thus being prodeced of grass products. Defects are mainly foreign body defects such as sand, knot and wave reinforcement. What may directly affect the quality of glass are sidewall block and brick kiln bottom. I hope my answer can help you.

- Q: What is the definition and classification of amorphous fire resistance materials?

- 9.8. brick made of refractory bone material and powder material can be used directly or after adding appropriate liquid formulation Refractory paint. Refractory slinging material 6. Prefabricated cubes, bonding agent or other additives. fire-resistance sparying material compround additives. Refractory pressed into the material, binder. Refractory ramming material 3, The material is a new fire proof material without calcination Heavy aggregate and lightweight aggregate: Inorganic binding agent and organic bond, its fire resistance is not less than 1580. Refractory castables 2 mouldable refractory Classification according to the type of bonding agent: 1. Classification according to refractory aggregate. According to the production and construction method, refractory mud or refractory mire, with a certain proportion of the mixture

- Q: Fire resistance and evaluation of refractory for casting

- Because of their different shapes and conditions, various refractories are used to explain their fire resistance with different indexes, and the test methods are also different. In general, the refractoriness of unshaped refractories; the softening temperature of formed refractory products; the change of the reheating line of heat insulation materials at high temperature.

- Q: Which are roofing fireproofing material?

- (1) Foamed concrete is a kind of fire-proof thermal inuslation matertial featured by good fire resistance and thermal insulation. Besides, it is also characterized by excellent sound proofing, penetration resistance, easy construction, safety and environmental protection without toxin and pollution. (2) Foam glass is featured by light weight, small heat conductivity coefficient and water absorbption, non-inflammability, fire resistance, high strength, no moulding, corrosion resistance, non-toxin and stable physical and chemical properties and thus widely used petroleum, chemical engineering and underground construction. It is also featured by thermal insualtion, heat/cold preservation and sound absorbption and thus can be used for thermal insulation of external wall and roof of civil builduing. Foam glass is featured by stable chemical property, easy to be processed and not easy to deforme, and durable. (3) With slag, basalt and other natural ore as the main raw material, rock wool, mineral wool and its products are made by high temperature melting into fiber, and then processing with binder. It has low thermal conductivity, fire resistance, easy construction and good effects of energy saving and thus is highly cost-effective. (4) With phenolic foam material as main material, phenolic resin plate is made by foaming thermoset phenolic resin. It is featured by light weight, fire resistance, no burning in the air, no smoking, non-toxin, no dropping and non-embrittlement and thus is an ideal thermal insulation material used in HAVC projects. Due to its high obturator formamen rate, low heat conductivity coefficient, good thermal insulation, water resistance and water vapor permeability, phenolic foam is an ideal thermal insulation material.

- Q: which is better as household fireproof material ?

- the thickness recommended is 1mm or more # 304 stainless steel plate, refractory corrosion-resistant, easy to clean. It now appears that among the most common fireproof material, asbestos is the best. But the asbestos harmful effect is also great, especially for lung damage. Now on the market, the polyurethane, polystyrene, rock wool glass wool, phephenolic aldehyde fireproofingthermal insulation board. But now the phenolic aldehyde fireproofing thermal insulation board has superior performance! phenolic aldehyde containing only carbon, hydrogen and oxygen atoms, when subjected to pyrolysis, except small amounts of CO gas, the other will not produce toxic gases, maximum smoke density is 5.0%.

- Q: What are the specifications of fireclay bricks?

- Dimensions of refractory bricks : 230 * 115 * 65mm

Send your message to us

High-Quality Ferro Silicon Raw Materials for Refractory Applications in South Korea

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords