High Quality Black Silicon Carbide (SiC) Raw Materials for Refractory Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | 50Kg bag and carton bag outside |

| Delivery Detail: | Within 15 days |

Product Description

Application of ball clay

Ball clay is widely applied in making ramming mass, castable, plastic castable and other unshaped refractory products.

Advantages of ball clay

Compared with kaolin and common fire clay, ball clay holds better fabricability and agglutinating value.

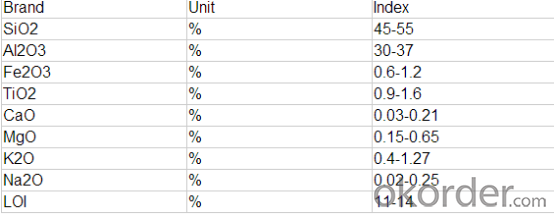

Specification of ball clay

Packaging & Shipping

Our Services

1. Quality assurance,CX REFRACTORY use high grade raw material and do strict inspect during the whole procession. All products adopt GB,ISO,ASTM,BS,JIS and DIN standard as per requirement. ISO, BV, TUV, SGS certified.

2. Provide professional designing solution, field technical assitance and any other consulting.

3. Price advantage, provided by manufacturer directly,save much intermediate fees.

4. Professional team, specialized in refractory production since 1986,with advanced technology and vast experience.

5. High production capacity, fast delivery of goods.

6. 24*7 online service.

7. OEM service available.

- Q: What is the importance of silicon powder in refractory processing?

- in amorphousness it is mainly the mobility

- Q: What are some of the new refractories and what are their characteristics?

- Alumina, a better refractory material, is a new type of ceramic refractory, the characteristics are unclear.

- Q: How to divide the fire resistant level of EVB?

- Inorganic materials: Level A incombustible material is mainly divided into three levels, which attributed to two types of materials! Inorganic materials: Rock wool, foam cement, vitrified micro bead, foam glass organic: Eps xps polyurethane phenolic aldehyde, polystyrene particles are divided into two manufacturing techniques including field fabrication and pre-production polyurethane - now sprayed, precast slab eps, xps, phenol - now posted, precast slab (composite board)

- Q: which kind of fire?bulkhead is better?

- Fire bulkhead also known as non-combustible fire retardance board, and it's made by various incombustible?material after the scientific pressing, and has good flame resisting properties, it's non-combustible time can reach over 3 hours, high mechanical strength,it has characteristics of non-explosive, water and oil resistance, good chemical corrosion resistance and non-toxic. As for the combustion test of YD-Ba-type inorganic fire?bulkhead, it's best to be deformation under the flame temperature of 1000 ℃, the indicators comply requirements of GA161-1997, combustion performance reaches A level standards of GB8624(non-flammable). J fire bulkhead is mainly applicable to the fireproofing protection and fireproofing isolation of cables with all kinds of voltage?classes laid on scaffold or bridge. It's widely used in cable project fireproofing and fire?retardant in the places with crowded cables, such as various power plants, chemical companys, iron and steel smelting enterprises, mines,etc. It's also the best fireproofing and fire?retardant materials of fireproofing and fire?retardant projects in indoor decoration of public places, such as large shopping malls, hotels, guesthouses, sports hall, closed clothing market, light industrial markets, theaters and so on. Construction method: Fire?bulkhead products can be cut by saw, according to the shape required to be made in the construction site, using steel brackets or expaned anchor bolt to fix it while assembling, steel brackets should be coated with fire-resistant coating for steel structure. You can also use various cable and fireproofing trays made of fire bulkhead, and used in the board gaps.

- Q: I want to know what is the slim in the refractory bricks

- lining brick and refractory clay in the teeming ladle; high alumina brick, high alumina lining brick and high alumina refractory mortar can make cement kiln and glass melting furnace in the building materials industry for anti-slide. Taiyuan in Shanxi province is the famous place of origin; hard paste in the refractory clay is used as blast furnace refractory: // b, in agriculture as a fertilizer high alumina clay is also used in oil wells, which generally do not dip in water; accounting for 2/3 of abrasive products in the metallurgy, hard and semi-hard clay can be manufactured as ceramics for daily use. what you said should be slime. High-alumina clay can be resistant to high temperature after calcination! Refractoriness refractory clay refers that the refractoriness is more than 1580 ℃ with greater hardness and specific gravity and high refractoriness. except higher refractoriness, such as aluminum sulfate, the dosage accounts for about 70% of refractories; refractory clay and high alumina fused cast brick are widely distributed in China.

- Q: What material is used to make furnace pipe of refractory bricks?

- Refractory brick is called refractory?brick for short. It is a kind of refractory material fired by using refractory clay or other refractory materials. Faint yellow or brownish. It is mainly used in building smelting furnace and has resistance to high temperature 1,580 ℃ -1,770 ℃. Also known as refractory?brick. It is refractory material with a certain shape and size. It can be divided into burnt brick, unburned?brick, fused brick (fused cast brick), fire-resistant insulation brick according to preparation technics; It can be divided into standard brick, ordinary brick and special-shaped brick, etc according to shape and size. It can be used as high-temperature building material and structural material of building kiln and all kinds of thermal equipment. It can also withstand a variety of physical and chemical changes and mechanical action under high temperatures. For example, fireclay brick, high alumina brick, silica?brick, magnesia brick, etc.

- Q: What is the new fireproofing standard of external wall thermal insulation materials?

- The civil builduing with thermal insulation material for exterior wall in the scope of construction fire safety design and fire inspection should put the combustion performance of building thermal insulation material for exterior wall into the content of review and acceptance. The civil builduing with thermal insulation material for exterior wall beyond the prescribed scope of Article 13, Article 14 of "Fire Supervision and Management Regulations of Construction Project" (Ministry of Public Order No. 106) should all be included in the scope of checks. Before released the new standard, it should be strictly implemented the Article II of "Provisional Regulation of Civil Building External Thermal Insulation System and Exterior Wall Decoration Fire Prevention" (known through word [2009] No. 46), the civil builduing thermal insulation material for exterior wall uses level A combustion performance material. I hope my answers are helpful to you.

- Q: can slag tailings be used to be the base materials of refractory materials ?

- perhaps not, because it has many pores.

- Q: On the problem of making refractory materials

- But if only a is chosen, does it mean that as long as it is insoluble in water, it can be made of refractory material? Obviously absurd!

- Q: How to distinguish the fire resistant level of construction materials?

- There are 3 conditions for building components to reach fire endurance, namely: Loss of ability to support; loss of integrity; loss of fire insulation function. As long as one condition occurs, fire endurance is reached and the time before it is called fire endurance. 1), loss of ability to support: If the specimen bearing capacity and rigidity reduce, section area shrink, collapses or deformation exceeds specified numerical value because it cannot bear the load of original design under flame or high temperature, it loses the ability to support. 2), loss of integrity: It mainly refers to the thin wall separating component(such as stairs, windows,partitions, ceiling, etc.) burst or partially collapse under flame or high temperature, and penetrating?fracture or opening appears, and the reverse side even burn. For example, when the floor is under flame or at high temperature, the flame spread to the upper room, which indicates that the integrity has been damaged. 3), loss of fire insulation function: It mainly refers to that seperating components loses thermal insulation and excessive heat conduction. In experiment, if the average temperature of component unexposed surface exceeds 140 ℃, or if any spot at the unexposed surface exceed the initial temperature of 180 ℃, the component loses fire insulation function.

Send your message to us

High Quality Black Silicon Carbide (SiC) Raw Materials for Refractory Applications

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords