Semi dull white FDY polyester filament yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of FDY Yarn

Material | 100% polyester |

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

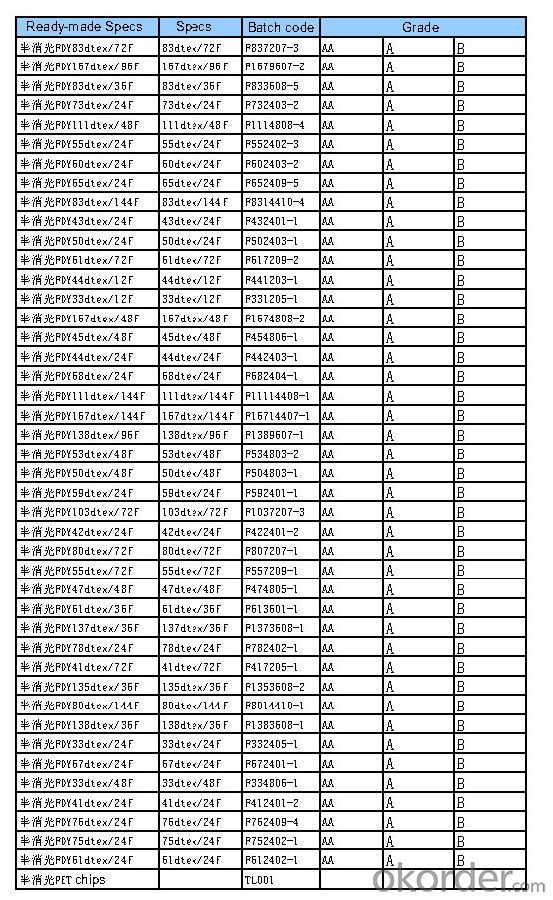

Specification | 11-167dtex, 12-144F |

Regular Specifications

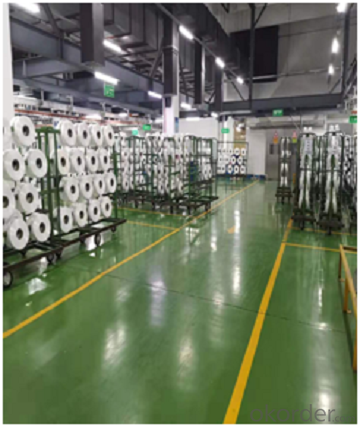

Production Facilities of FDY Yarn

We have the most advanced production system DSC. The whole production process is conducted and supervised by the operating platform. Meanwhile, there are 10 TMT fully automatic winding machine and Robot packaging system which highly improves the production efficiency and avoids manual mistakes.

Production Capacity of FDY Yarn

The production capacity is 200,000 TONS per year for now and it will be of 500,000 per year after the erection of the second production line.

Package of FDY Yarn

The FDY yarned is packed by plastic film, paper board, foam board and wooden pallets. Each pallets is about 640-720kg. Box package is also available.

Advantage of Us:

Subsidiary of Stated-owned group, reliable and trustable

Industry leader in the PET chip and yarn fields

On time delivery and prompt response

Well-funded and accept different kinds of payment terms

- Q: Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- Cotton yarn is made of cotton fiber by spinning the yarn, processed by the stock after the cotton line. According to the different spinning process, can be divided into carded yarn and combed yarn. (1) carded yarn: cotton fiber is the ordinary spinning system spinning yarn

- Q: Textile waste silk (abandoned side yarn) what purpose ah?

- Textile industry more and more waste, need to use. The rapid development of chemical fiber industry, for the development of non-woven technology provides a wealth of raw materials, broaden the possibility of product development. Many traditional textiles for the final application, targeted poor

- Q: What is the process of towel in the textile?

- Determine the yarn count, warp and weft density, the number of warp yarns and weft yarns (especially yarn-dyed), with a number of pieces, wearing a reed method, jacquard to determine the installation of wear method (in layman's terms, , Wear, mix wear method), reed width, shaft width, yarn consumption, hair times, under the specifications and weight, and so on

- Q: There are several kinds of yarn in textile mill

- Usually, according to the yarn used in raw materials, yarn thickness, spinning method, spinning system, yarn structure and yarn use classification. According to the yarn raw material points 1. Pure spinning Pure spinning is a yarn made of a fiber material such as cotton yarn, wool yarn, hemp yarn and silk spinning. This type of yarn is suitable for making pure textile.

- Q: What is the textile fancy yarn theory?

- 4, circle line, decorated line to form a closed circle, wrapped in solid yarn. 5, knot line, decorated yarn to spiral around the core line, but the interval to throw the ring shape. 6, chenille line, in the core dumb sandwiched horizontal yarn. The yarn ends of the yarn are loose. 7, diamond-shaped metal wire, in the metal core (from aluminum foil or sprayed metal material jacket with a transparent protective film made) the outer winding of another color, fine decorative lines and fixed line, with a diamond pattern effect.

- Q: What are the types of cotton yarns?

- (2) according to the principle of spinning points: ① free spinning (such as air spinning, 赛 spinning) ② both ends of the holding of spinning (such as ring spinning, compact spinning) there is a more popular in recent years is the vortex Spinning, this textile technology is the use of air swing principle to improve.

- Q: What is the reason why the yarn is spinning

- Spinning machine without insurance yarn, loom with a large circular machine, latitude and longitude knitting machine, the traditional shuttle weaving machine, etc.

- Q: Textile spinning mill management system

- The same for the financial, the need to be able to generate reports from time to time to understand the day, month, quarter, year of the report statistics, and for sales need to be able to grasp the customer's information and inventory, and further sales, production, procurement, etc. And so on a series of work processes.

- Q: From the yarn to the finished textile fabric production process

- Including aliphatic PA, fat-aromatic PA and aromatic PA. Among them, the aliphatic PA varieties, large output, widely used, the name of the monomer by the specific number of carbon atoms

- Q: Is the thickness of the yarns 40S and 80S / 2 in the textile fabric the same?

- The thickness is basically the same, but 40S is a single yarn, the general twist is Z twist, 80S / 2 is the strand, twist to S twist, is made of two 80S single yarn twisted

Send your message to us

Semi dull white FDY polyester filament yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords