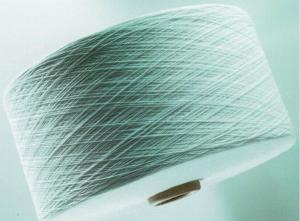

100% Modal Yarn

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 TON m.t.

- Supply Capability:

- 500 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of 100% Modal Yarn:

1, Modal Yarn feel soft, fine drapability and comfortable to wear.

2, Modal Yarn absorbs moisture permeability performance, superior cotton fabrics, is the ideal of personal care products, clothing and fabric for health and human physiological cycles.

3, Modal Yarn's color is gorgeous, the amount of light, it is a kind of natural silk fabrics.

4, Modal Yarn takes stable performance, compared with cotton, the test by 25 times after washing, will increasingly hard and Modal Yarn, on the contrary, wash the soft, wash more beautiful.

5, Modal Yarn garment effect is good, a strong, have natural wrinkle resistance and iron free sex, make people more convenient and natural.

- Q: How does textile twist yarn identify?

- Observe the fiber near the flame, contact with the flame, leaving the flame produced by a variety of different phenomena and the combustion of the odor, the post-combustion residue to identify the fiber type.

- Q: 40s / 2 What does it mean, is this yarn 40 or 80?

- 21S / 1 x 40S / 2 means: 100% cotton fabric is 21S (count) / 1 (single stock) x 40S (count) / 2 (double

- Q: How much does it cost to do a small cotton textile mill?

- You are really interesting, it is estimated that you have not even into the spinning mill it! From the beginning of the cotton is the spinning mill is necessary! The front of the machine do not, unless you want to start from the cotton start

- Q: What is the yarn inside the textile industry is what kind of yarn?

- As for the thickness of the yarn, is to rely on weighing to determine. And the twist of the yarn, measured with a twist meter

- Q: What are the types of cotton yarns?

- (3) according to the cotton grade points: ① carded yarn: is not through the combing process spinning process spinning ring yarn, for the general needle, woven fabric; ② combed yarn: with good quality cotton Fiber as raw materials, spinning than the carding yarn to increase a combing process, spinning yarn quality, for the weaving of high-grade fabrics, such as high-level poplin, fine cloth, etc .; ③ waste spinning: refers to all the spinning process Processing down the waste cotton as raw materials spinning yarn, used for weaving low-grade cotton blankets, velvet and foreskin cloth, etc .; ④ new spinning: spinning with a new spinning system yarn.

- Q: Textile class 21 yarn, 32 shares of what is the meaning of goods ah

- The finer the yarn, the larger the number, the thinner the fabric. In addition there is the difference between single yarn and yarn, single yarn refers to a single yarn, strands refers to the single yarn twisted by the synthesis of the strands

- Q: What is the reason why the yarn is spinning

- Spinning machine without insurance yarn, loom with a large circular machine, latitude and longitude knitting machine, the traditional shuttle weaving machine, etc.

- Q: Textile yarn 75d ppt memory silk how much money meal?

- Made with its fabric soft, its performance can be comparable with silk, silky luster and comfortable feel

- Q: What is the difference between mesh cloth and Bali yarn?

- It has a unique elasticity function. Mesh fabric mesh structure, in the production process after a high temperature stereotypes, when subjected to external forces, can follow the direction of force extension, when the pull force to reduce the withdrawal, the mesh can be restored to the original shape. Mesh cloth is made of tens of thousands of polymer synthetic fiber yarn, refined from the oil out. Made of knitted weave, it is not only firm, able to withstand high strength of the tension and tear.

- Q: From the yarn to the finished textile fabric production process

- Nylon modified varieties such as nylon, single-cast nylon (MC nylon), reactive injection molding (RIM) nylon, aromatic nylon, transparent nylon, high impact (super tough) nylon, electroplated nylon, conductive nylon , Flame retardant nylon, nylon and other polymer blends and alloys, to meet the different special requirements, widely used as metal, wood and other traditional materials substitutes, as a variety of structural materials.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | ISO9001:2000 ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

100% Modal Yarn

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 TON m.t.

- Supply Capability:

- 500 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords