FDY polyester filament yarn raw white semi-dull FDY bright trilobal polyester yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

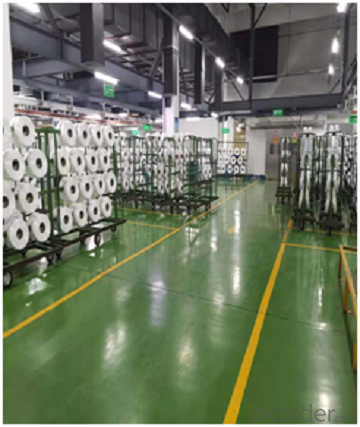

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

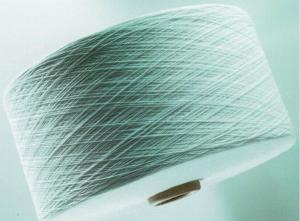

Product Description of FDY Yarn

Material | 100% polyester |

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

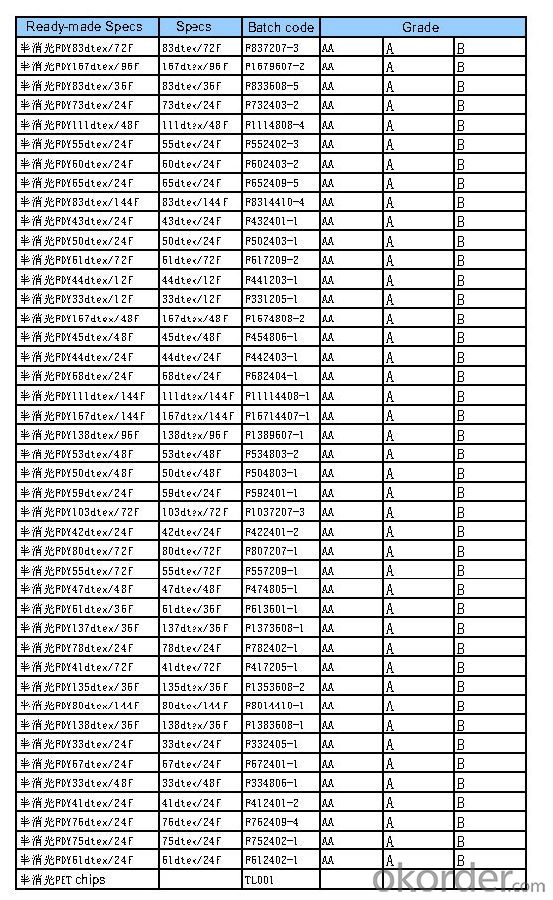

Specification | 11-167dtex, 12-144F |

Regular Specifications

Structure:

1). sheath-core structure: low melting polyester+polyester, Low melting polyester content:30%~40%

2). 100 pure low melting polyester

Feature:

Low melting polyester will be melted at 110/180 degree Celsius and be endowed with adhesive property.

Use low melting polyester is harmless, and enhances the strength of the fabric.

The fabric made with low melting polyester yarn is with high strength, washable, stiff and smooth, easy care.

Low melting polyester yarn owns good adhesiveness and stability, adhesive quickly.

The processing is simple, low energy consumption, nonhazardous, no pollution, Eco-friendly.

Application and suggestion:

1. The adhesive of two layers of sports shoe Upper material —FDY 50D/75D

2. Soft curtain, Zebra curtain, Roman curtain—FDY 75D/150D

3. Vertical blinds—FDY 250D

4. Filter net for air condition—FDY 30D/50D/75D/150D

5. Electromagnetic wire: PET-Glass fiber blended fiber—FDY 50D/75D

6. Garment lining cloth for suit, tie, hat, etc. —FDY 150D/50D/420D

7. Warp knitting fabric such as: Stiff mesh fabric, medical/food filter net, inner car decoration.

8. Top-grade eco-friendly filter material

9. Other applications: protective gloves, dust gauze, top-grade window screen, invisible screen, etc.

- Q: What does JC40S cotton yarn mean?

- Cotton yarn production methods are more complex, in general, there are two kinds of spinning methods, that is, comb cotton spinning and combing spinning. (1) carding cotton spinning process: with cotton → open cotton → carding (2) combing spinning process: with cotton → open cotton → carding → combing → parallel → roving → spun yarn → post-processing → finished product inspection.

- Q: How does textile twist yarn identify?

- Different textile fibers, chemical composition is different, in the combustion process of course have different phenomena

- Q: What is the difference between textile sizing and paper making?

- Modified starch is currently used industrially, mainly acid modified starch, oxidized starch, phosphate starch, acetate starch, carboxymethyl starch, cationic starch, amphoteric starch, grafted starch.

- Q: What is the reason why the textile yarns are yarn

- The yarn is mainly used for hand and weaving. Wool yarn is made of wool as raw materials twisted from the twist to the yarn; wool is also called cashmere, wool is made of raw materials from the strands

- Q: There are several yarns of textile mills

- Blended yarn Blended yarn is made of two or more fibers spinning yarn, such as polyester and cotton blended yarn, wool and viscose blended yarn. Such yarns are used to highlight the fabric of the advantages of both fibers. According to the thickness of yarn 1. A fine yarn of 32 or more (18 in. And below). Such yarns are suitable for thick fabrics such as tweeds and coarse fabrics

- Q: Textile class 21 yarn, 32 shares of what is the meaning of goods ah

- The finer the yarn, the larger the number, the thinner the fabric. In addition there is the difference between single yarn and yarn, single yarn refers to a single yarn, strands refers to the single yarn twisted by the synthesis of the strands

- Q: What is the reason why the yarn is spinning

- The insurance yarn is woven out of cloth on the edge of 0.5 to 1 cm of the lock side, is to prevent the yarn spread out the yarn, the insurance yarn is more important than the weaving yarn

- Q: Men's sweaters with what yarn?

- The end of the proposed: the use of expanded cotton nitrile or other cotton blended yarn, yarn yarn price: 45-55 yuan / Kg or so, high-end: the proposed use of linen cotton or wool composition of the yarn, made of clothing look high fashion, The price will be relatively high.

- Q: What is the knitting yarn and the woven gauze?

- Woven yarn requirements: strong high, less neps. Knitted yarns are relatively strong without weaving yarns, but the details are demanding and the twist is also free of woven yarn

- Q: Is the thickness of the yarns 40S and 80S / 2 in the textile fabric the same?

- The thickness is basically the same, but 40S is a single yarn, the general twist is Z twist, 80S / 2 is the strand, twist to S twist, is made of two 80S single yarn twisted

Send your message to us

FDY polyester filament yarn raw white semi-dull FDY bright trilobal polyester yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches