Fascia Aluminum Coil for Roofing Application - Aluminum Color Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

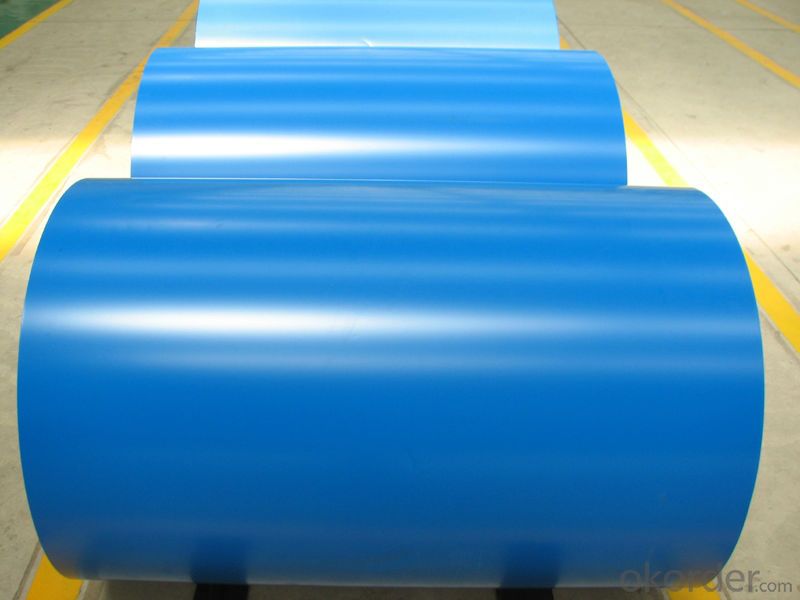

Structure of Aluminium Color Coated Coil for Roofing Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Color Coated Coil for Roofing Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Color Coated Coil for Roofing Application:

Aluminium Color Coated Coil for Roofing Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Is it safe or practical to use an electric iron as a heat source for an aluminum coil?

- <p>Using an electric iron to heat an aluminum coil is not advisable. Electric irons are designed to heat their own plates for ironing clothes, not to transfer heat to other materials like aluminum coils. The high temperature of an iron could damage the coil and potentially cause a fire hazard. Moreover, aluminum has a high thermal conductivity, which means it would dissipate heat quickly, making it inefficient to use an iron for this purpose. Always use heating elements specifically designed for the material you intend to heat.</p>

- Q: What are the common surface protection methods for aluminum coils?

- There are several common surface protection methods for aluminum coils that are widely used in various industries. These methods aim to protect the surface of the aluminum coils from corrosion and other forms of damage, ensuring their long-term durability and performance. One of the most common surface protection methods for aluminum coils is anodizing. Anodizing involves immersing the aluminum coil in an electrolyte bath and applying an electric current to create a protective oxide layer on the surface. This oxide layer not only enhances the appearance of the aluminum coil but also improves its resistance to corrosion, scratching, and wear. Another popular surface protection method is coating. This involves applying a protective layer of paint or coating material onto the surface of the aluminum coil. Coatings can be applied through various techniques such as electrostatic spraying, roll coating, or coil coating. These coatings provide a barrier between the aluminum surface and external elements, protecting it from moisture, UV radiation, and other environmental factors that can cause corrosion and damage. In addition to anodizing and coating, aluminum coils can also be protected through the use of protective films. These films are usually made from polyethylene or similar materials and are applied to the surface of the coil as a temporary protective layer. Protective films help prevent scratches, abrasions, and other forms of damage during transportation, storage, and installation. Once the aluminum coil is ready to be used, the protective film can be easily peeled off, leaving a clean and undamaged surface. Furthermore, aluminum coils can be protected through proper storage and handling practices. Storing the coils in a dry, clean, and well-ventilated area, away from corrosive substances, can significantly prolong their lifespan. Handling the coils with care and using appropriate lifting and transportation equipment can also prevent physical damage that can compromise their integrity. Overall, the common surface protection methods for aluminum coils include anodizing, coating, the use of protective films, as well as proper storage and handling practices. By employing these methods, aluminum coils can be effectively safeguarded against corrosion, scratching, and other forms of damage, ensuring their optimal performance and longevity.

- Q: What are the different types of alloys used for aluminum coils?

- Aluminum coils are commonly made using several different types of alloys. The most frequently used alloy for aluminum coils is 3003, which is known for its excellent corrosion resistance and moderate strength. It finds its application in roofing and siding where high strength is not a requirement. 5052 is another alloy that is commonly used for aluminum coils. This alloy possesses good weldability and formability, making it suitable for a wide range of uses. In the automotive industry, it is often employed for body panels and fuel tanks. 6061 is a popular choice for aluminum coils due to its outstanding strength. It is frequently used in structural applications, such as aircraft parts in the aerospace industry and structural components in the construction industry. Additionally, other alloys like 1100, 5005, and 8011 are also used for aluminum coils. Each of these alloys has distinct properties and characteristics that make them suitable for different applications. For instance, 1100 is known for its high electrical conductivity and is commonly used in electrical applications. On the other hand, 8011 is frequently utilized for packaging and food containers due to its excellent corrosion resistance. In conclusion, the various alloys used for aluminum coils include 3003, 5052, 6061, 1100, 5005, and 8011. These alloys possess different properties and characteristics, making them suitable for a wide range of applications across industries like automotive, aerospace, construction, and packaging.

- Q: Can aluminum coils be used for architectural facades?

- Indeed, architectural facades can make use of aluminum coils. The lightweight, durable, and versatile nature of aluminum makes it a favored option for such purposes. With the ability to mold aluminum coils into diverse shapes and sizes, one can create unique and visually pleasing facades. Furthermore, aluminum demonstrates resistance to corrosion, rendering it suitable for outdoor use. Moreover, aluminum allows for easy coating or finishing, enabling an improved aesthetic appeal and protection against environmental factors. All in all, aluminum coils offer an economically viable and environmentally friendly alternative for architectural facades.

- Q: What is the primary function or use of a spring steel wire coil?

- <p>A spring steel wire coil is primarily used for its high elasticity and strength. It is designed to return to its original shape after being deformed, which makes it ideal for applications requiring resilience and durability. Common uses include the manufacturing of various types of springs, such as compression springs, torsion springs, and extension springs, found in automotive suspensions, mechanical devices, and industrial equipment. The coil's properties also make it suitable for applications in furniture, electronics, and other industries where a reliable and consistent force is needed.</p>

- Q: I'm 14 an was told that aluminum free deodorant would stop yellow stains on my white shirts, so which female deodorant would help stop yellow stains

- Deodorant with aluminum also causes breast cancer. I use Toms of Maine deodorant, which is aluminum-free.

- Q: Why does aluminum foil barely get hot in the oven, but catch fire in the microwave?

- The okorder /

- Q: Are aluminum coils suitable for pharmaceutical vial caps?

- Pharmaceutical vial caps can indeed be made from aluminum coils. When it comes to pharmaceutical packaging, aluminum is highly favored thanks to its exceptional barrier properties. These properties effectively shield the vials' contents from moisture, oxygen, and other harmful substances. Aluminum coils can be easily molded into caps of various sizes and shapes, accommodating different types of vials. Another advantage is that aluminum is a lightweight material, which makes transportation and handling hassle-free. Additionally, aluminum is resistant to corrosion, ensuring that the vial caps remain intact throughout storage and usage. In summary, due to their barrier properties, versatility, and durability, aluminum coils are a suitable option for pharmaceutical vial caps.

- Q: How do aluminum coils contribute to the durability of structures?

- Aluminum coils contribute to the durability of structures due to their inherent properties such as corrosion resistance, lightweight nature, and high strength-to-weight ratio. These coils, when properly installed, form a protective layer on the structure, shielding it from environmental factors like moisture, UV rays, and temperature variations. This corrosion resistance ensures that the structure remains intact and free from rust, extending its lifespan. Additionally, the lightweight nature of aluminum coils reduces the load on the structure, making it less prone to stress and allowing for easier installation. Overall, the use of aluminum coils enhances the durability of structures by providing long-lasting protection and structural integrity.

- Q: How are aluminum coils manufactured?

- Aluminum coils are typically manufactured through a process called continuous casting and cold rolling. In this process, molten aluminum is poured into a mold to form a solid slab. The slab is then passed through a series of rolling mills to reduce its thickness and achieve the desired gauge. This rolling process is repeated several times until the desired thickness and surface finish are achieved. The coils are then cooled, trimmed, and packaged for distribution.

Send your message to us

Fascia Aluminum Coil for Roofing Application - Aluminum Color Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords