Fabric for Fiberglass - E-Glass Surfboards Fiberglass Fabric for Building

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

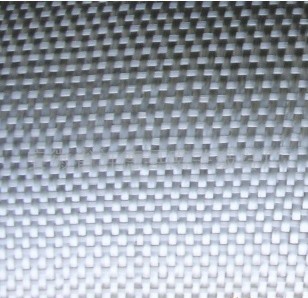

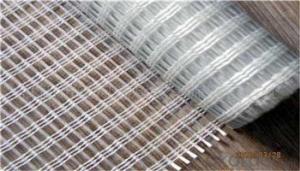

Introduction of E-glass Surfboards Fiberglass Fabric:

Fiberglass fabric is weaved of high quality C-glass fibers or E-glass fibers.

Fiberglass fabric is a good construction material with the following excellent properties

* Dimensional stability

* High Strength

* Fire resistance, High heat resistance

* Good chemical resistance

* Durability

* Forms around complex surface shapes

Application of E-glass Surfboards Fiberglass Fabric:

Fiberglass fabrics can be used in a variety of applications, including construction in waterproofing applications for roofing and foundation, wall treatment, pipeline joint wrap.

Packing of E-glass Surfboards Fiberglass Fabric:

Fiberglass fabric is wound on a paper tube with inner diameters of 50. 8, 76 or 152mm. Each roll is wrapped in a plastic bag, then to be packed in a carton box. The rolls are to be horizontally placed.

Width (cm): 90, 100, 127

Length (m): 100, 200, 300, 400

Storage of E-glass Surfboards Fiberglass Fabric:

Store rolls in a cool, dry location

Protect rolls from weather and other damage.

- Q: Can fiberglass fabric be used for making flags and banners?

- Yes, fiberglass fabric can be used for making flags and banners. Fiberglass fabric is known for its durability, strength, and resistance to weather conditions, making it an ideal material for outdoor applications such as flags and banners. It is lightweight and flexible, allowing for easy handling and installation. Additionally, fiberglass fabric can be printed on using various techniques, ensuring vibrant and long-lasting colors on the flags and banners. Overall, fiberglass fabric is a reliable choice for creating flags and banners that are both visually appealing and durable.

- Q: Can fiberglass fabrics be used for sports or recreational equipment?

- Yes, fiberglass fabrics can be used for sports or recreational equipment. Fiberglass is known for its high strength and durability, making it an ideal material for various sports and recreational applications. It is commonly used in the construction of equipment such as kayaks, canoes, surfboards, skateboards, and even sporting goods like hockey sticks and golf club shafts. The lightweight nature of fiberglass also contributes to its popularity in these industries, as it allows for improved maneuverability and performance. Additionally, fiberglass fabrics can be molded into different shapes and sizes, providing versatility in the design of sports and recreational equipment. Overall, fiberglass fabrics are a reliable and widely-used material for the manufacturing of sports and recreational equipment.

- Q: Emulsion rubber asphalt waterproof paint what brand is good

- It and the solvent type regenerated rubber asphalt waterproof coating as seamless waterproof membrane in the complex formed on the surface, there is a certain degree of flexibility and durability, with water as the dispersion medium, with non-toxic, tasteless, non combustion advantages, safe and reliable, does not pollute the environment, can be at room temperature under cold construction and surface construction at a slightly damp and no water, and wide material source, low price. It is also a kind of thin coating, which is coated with thin film in order to reach the required thickness.

- Q: Do fiberglass fabrics have any electrical conductivity properties?

- Fiberglass fabrics lack electrical conductivity, meaning they do not possess any properties that allow them to conduct electricity. As an insulator, fiberglass is incapable of conducting electrical current. This characteristic renders it suitable for a wide range of applications that demand electrical insulation, including electrical insulation sleeves, circuit boards, and protective covers for electrical equipment. Moreover, fiberglass fabrics find common usage in industries where insulation from heat and fire is indispensable, further emphasizing their non-conductivity to electricity.

- Q: What are the different surface textures available in fiberglass fabric?

- There are various surface textures available in fiberglass fabric, including smooth, textured, woven, satin, and twill.

- Q: Are fiberglass fabrics resistant to mildew or fungus?

- Yes, fiberglass fabrics are generally resistant to mildew or fungus. This is because fiberglass is a non-porous material that does not provide an ideal environment for the growth of mold, mildew, or fungus. Additionally, fiberglass fabrics are often treated with special coatings or finishes that enhance their resistance to these types of organisms. However, it is important to note that while fiberglass fabrics are generally resistant to mildew or fungus, they are not completely immune. If the fabric is exposed to very high levels of moisture or is not properly maintained, it is still possible for mildew or fungus to develop. Therefore, it is recommended to follow proper cleaning and maintenance procedures for fiberglass fabrics to ensure their longevity and to prevent any potential growth of mold or mildew.

- Q: Can fiberglass fabric be used for insulation in food processing plants?

- Yes, fiberglass fabric can be used for insulation in food processing plants. It is a commonly used material due to its heat resistance, durability, and ability to provide thermal insulation. Additionally, fiberglass fabric is non-toxic, non-absorbent, and can withstand high temperatures, making it suitable for use in food processing environments.

- Q: How does fiberglass fabric perform in high-pressure applications?

- Fiberglass fabric performs well in high-pressure applications due to its excellent strength, durability, and resistance to deformation. It can withstand high levels of pressure without compromising its structural integrity, making it a reliable choice for various industries such as aerospace, automotive, and manufacturing.

- Q: What are the different types of fiberglass fabrics?

- Various types of fiberglass fabrics are available, each possessing its own distinctive characteristics and applications. Some commonly used types include: 1. E-Glass Fabric: This particular fiberglass fabric is widely utilized due to its exceptional electrical insulation properties and high tensile strength. It finds application in boat construction, automotive components, and aerospace parts. 2. S-Glass Fabric: S-glass fabric is a superior alternative to E-glass, offering higher tensile strength and better impact resistance. It is suitable for applications demanding superior strength, such as military equipment and high-performance sports gear. 3. C-Glass Fabric: C-glass fabric is resistant to chemical corrosion, making it ideal for applications where exposure to chemicals is a concern. It is commonly employed in chemical plants, wastewater treatment facilities, and other industrial settings. 4. A-Glass Fabric: A-glass fabric is an alkali-resistant type of fiberglass fabric extensively used in the construction industry to reinforce cement and concrete structures, including bridges and buildings. 5. Roving Fabric: Roving fabric consists of untwisted fiberglass strands and is typically utilized in applications requiring high strength and dimensional stability, like wind turbine blades, pipes, and pressure vessels. 6. Chopped Strand Mat (CSM): CSM is a fiberglass fabric composed of randomly oriented chopped strands held together with a binder. It is commonly employed in applications requiring a smooth and uniform surface finish, such as boat hulls and automotive parts. 7. Woven Roving: Woven roving is a heavy-duty fiberglass fabric characterized by closely woven strands. It is renowned for its high strength and stiffness, making it suitable for applications necessitating structural reinforcement, such as boat hulls, wind turbine blades, and automotive body panels. Ultimately, the selection of fiberglass fabric depends on the specific requirements of the application, encompassing strength, electrical insulation properties, chemical resistance, and surface finish.

- Q: How do fiberglass fabrics compare to other types of fabric in terms of strength and durability?

- Fiberglass fabrics are highly regarded for their remarkable strength and durability, making them a favored option in multiple industries. In comparison to alternative fabric types, fiberglass stands out due to its unique attributes. To begin with, fiberglass fabrics possess outstanding tensile strength, which refers to their ability to resist stretching or breaking under tension. This strength surpasses that of most natural or synthetic fabrics by a significant margin. As a result, fiberglass fabrics are highly resistant to tearing and can withstand heavy loads without compromising their integrity. This renders them ideal for applications that require strength and durability, such as in the construction, automotive, and aerospace sectors. Moreover, fiberglass fabrics exhibit exceptional resistance to abrasion, chemicals, and extreme temperatures. These fabrics have a low coefficient of thermal expansion, meaning they do not expand or contract significantly when exposed to temperature fluctuations. This characteristic allows fiberglass fabrics to maintain their structural integrity even in extreme environments, including high heat and cold. Additionally, fiberglass fabrics are highly resistant to chemical corrosion, making them suitable for use in corrosive or acidic environments. Furthermore, fiberglass fabrics offer exceptional dimensional stability. Unlike certain other fabrics that may shrink or stretch over time, fiberglass fabrics retain their shape and size even under prolonged stress or exposure to moisture. This characteristic ensures the longevity and reliability of fiberglass fabric products. Overall, fiberglass fabrics demonstrate superior strength and durability when compared to other fabric types. Their high tensile strength, resistance to abrasion, chemicals, and extreme temperatures, as well as excellent dimensional stability, make them a dependable choice for various applications where strength and longevity are crucial.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Fabric for Fiberglass - E-Glass Surfboards Fiberglass Fabric for Building

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords