Emulsion Cooling and Lubricating Oil Decanter Centrifuge

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Emulsion Cooling and Lubricating Oil Decanter Centrifuge

Applications:

Decanter centrifuge is a horizontal centrifuge with continuous feeding and continuous dischargingThe settling speed is determined

by particle size,particle shape,difference in density between solidsand liquids as well as their viscosity.

Features:

l All parts coming into contact with the product are made of stainless steel

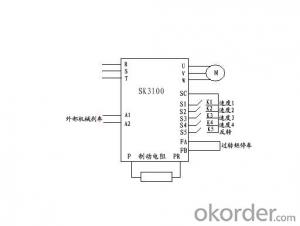

l 3-phase AC motor for controlled torque starting via frequency converter

l Approximately 80 to 90% of the oil is recovered.

l Low personnel costs due to continuous and automatic operation.

l Highest g-force for higher solids output

l Adjustable bowl speed via VFD

l Automatic adjustment of differential speed via VFD

l Two motor drive

l Belts for both primary motor and secondary

Application area

n Optimum dewatering of industrial and municipal sludge

n Optimized thickening of surplus sludge

n Partial dewatering of sludge for use in agriculture

n Treatment of industrial waste water

n Drinking water treatment

Decanter Centrifuge Gerneral Description :

When separator operation is no longer feasible due to high proportions of solids in the suspension to be processed, decanters are used. Decanters are horizontal, solids-oriented, solid-wall scroll centrifuges.

The solid bowl decanter centrifuge consists of two horizontal concentric rotating elements contained in a stationary casing.

The outer rotating bowl element is tapered so that the solids discharge from a smaller radius than the liquor. The inner element is a hollow hub screw conveyor with blade tips shaped to fit closely to the contour of the bowl.

Decanter Centrifuge Separation Theorem

1.Feed slurry is introduced into the conveyor hub. As the feed accelerates to the machine speed, the slurry is delivered by centrifugal force into the rotating bowl by

way of ports in the conveyor hub.

2.The solids settle through the liquor pool formed on the wall of the bowl. The solids are then conveyed, due to a slight differential between the screw conveyor and bowl,

up the drying beach to the solids discharge ports.

3.The clarified liquors are discharge in the opposite direction from adjustable overflow ports.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

- Q: I have a 2000 Monte Carlo SS that is stock, as in no aftermarket radio/electrical equipment and the fuse for the a/c and cruise. I noticed it popped when I bought the car and each time i put the same size fuse in or a bigger one, it automatically pops. I pulled the dash apart and all of the connections are good so I'm not sure of where to go.

- The fuse is a safety mechanism it will burn or pop as you say before damage can occur to the electronic component if it continually pops/ burns out that usually means there is a short in the wiring or on the part itself. Electrical problems can be a real pain in the a$$, even if you are experienced. So if you are not mechanically inclined I suggest not to try to track this problem down by yourself.

- Q: I have a dental Lab in Europe an want to move it to the States, maybe. Some of the equipment rates as high as 4kw, and the the total maximum draw is 15 kw for the whole lab. Can I wire a secondary breaker box in a building in the United States that is all 220?

- The first thing to do is examine along with your electricity supplier. You'll have to comprehend if the existing carrier to your residence will control the further load. If it is going to, you must hire a licensed electrician to put in one other panel for you. If this was once my residence i'd have a panel hooked up that will take it as much as eighty% of the existing carrier ability in case you wish to have so as to add extra circuits later. I do a variety of DIY but i'd have this finished by using a licensed pro and get a permit and inspection. That approach, if there may be ever a hearth or electrical damage your insurance company does not have a cop-out excuse to not pay given that the work wasn't accomplished by means of a pro and inspected.

- Q: I am assuming that the car is running when the items are being used.

- if the auto is running the battery will not as you say run down.

- Q: Curiosity just got the best of me. To be electrocuted one should make a complete circuit, right? What if you just touch the live wire and nothing else, you're not standing on anything, no ground. you're in mid air. Any thoughts? Thanks

- No. Your comment about a complete circuit is correct. Under the conditions you state you will not be electrocuted. One exception would be if the line frequency and voltage was high and you had substantial capacitance to ground you might be electrocuted.

- Q: I need to make some electrical schematics up for some older equipment. What programs are available other than AutoCAD? Not wanting to spend the $$$ for AutoCAD at this time and I'd prefer not to use paper and pencil.Thanks.

- Search: electrical CAD several choices are available. AutoCAD is not very good for schematics.

- Q: I cut a deal with my electrical shop teacher. If i tell him how we can relate an electrical class to ski lifts and snowmaking and learn about how they work and the electrical portion of them then hell take my shop to our local mountain Wachusett. Can anyone tell me how ski lifts and snowmaking equipment work and how i can relate it to electrical

- Your electric drive motors run on high voltage. Three phase 480v. All of your controls and safety systems run on low voltage. Battery powered, 24 or 48 volt. This is so that the lift can operate properly in the event of a power outage that cuts power to the drive. Lifts have backup drives, usually a diesel generator that can supply power to the electric drive motor, or an actual gas or diesel motor that can be coupled to the gearbox and drive the lift itself. Controls are usually a programmable logic control that monitor proper operation of different components of the lift and through a series of relays send power to the drive. Snowmaking is as aforementioned powered by large electric pumps and air compressors. Air and water are pumped usually from a central location and piped around the mountain to hydrants. Here, the snow guns are connected to the air and water. Some types of guns simply blow the water and air to make snow, while some have motors on them. These plug in to electrical pedestals, high voltage, that are located at the hydrant locations. These power large fans that help disperse the water and also control oscillating guns.

- Q: I know that B is flammable liquid and C is electrical equipment. thanks.

- A puts out fires of ordinary combustibles, such as wood and paper.

- Q: I know that I need to get an oscilloscope and a power supply but is there something else that I should plan on getting?

- Probably the best tools are a good quality digital multi meter, high voltage Pliers . oscilloscope is pretty expensive and is mostly usefull for Electronics not Electrical. Electronic is the voltages between 0-90 V and everything that you work more than 90V is Electrical and in that rate you must use saftey tools, which have been made for this purpose. If you are an electronics engineer who want to desige and make PCBs you need some softwares like Protel on your PC. if you like to work with Microcontrollers, you need some compiler and programmer specially made to program your microprocessors. A good clean workbench will help you to work properly, so it is better to buy some plastic shelves to put your components in . Don't forget to buy at least two breadboard, they will help you to test your projects before making PCBs, but be aware that Breadboard is not a good thing for high frequency projects. have a good one

Send your message to us

Emulsion Cooling and Lubricating Oil Decanter Centrifuge

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords