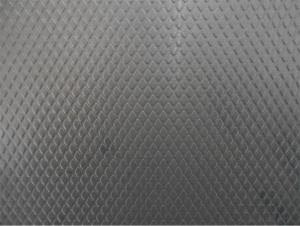

Embossed Aluminum Sheets as per American Standard ASTM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Auminium Sheet As Per American Standard ASTM Description

Auminium Sheet As Per American Standard ASTM is semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Auminium Sheet As Per American Standard ASTM

Auminium Sheet As Per American Standard ASTM | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Auminium Sheet As Per American Standard ASTM

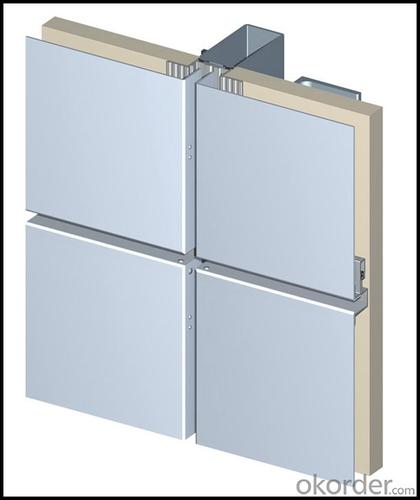

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Auminium Sheet As Per American Standard ASTM

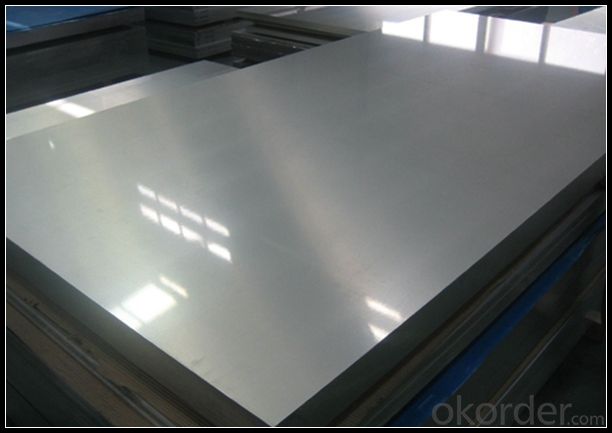

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Auminium Sheet As Per American Standard ASTM

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

6. Image of Auminium Sheet As Per American Standard ASTM

7. Package and shipping of Auminium Sheet As Per American Standard ASTM

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are the aluminum sheets suitable for aerospace applications?

- Indeed, aluminum sheets prove to be a suitable choice for aerospace applications. The aerospace industry widely embraces aluminum due to its exceptional strength-to-weight ratio, resistance against corrosion, and high thermal conductivity. These remarkable attributes render aluminum an ideal material for fabricating aircraft structures, such as fuselages, wings, and structural components. Moreover, aluminum can be effortlessly machined and shaped into intricate forms, enabling the production of lightweight and streamlined structures. Additionally, aluminum sheets can be easily joined using various techniques, including welding and riveting, ensuring the integrity of aerospace components. All in all, aluminum sheets are highly compatible with aerospace applications and have been extensively employed in the industry for numerous years.

- Q: I've narrowed down my next bike next year to either the cannondale Caad10 Ultegra version or the supersix 105 version, I've heard good things about both bikes, and at this point its gonna be down to preference after I ride it but, is aluminum stronger than carbon or vice versa? Will carbon crack easily or fail catastrophically?

- Aluminum Vs Carbon Road Bike

- Q: 5083 what is the density of the aluminum plate?

- 5083 aluminum alloy is Al-Mg-Si, use a wide range, especially in the construction industry cannot do without this alloy, alloy is the most promising. The main alloying elements as magnesium, has good forming performance, corrosion resistance, weldability, moderate intensity, is a kind of pure aluminum alloy aluminum density: 2.71 tons. / m3 (g / cm3) alloy aluminum density: 2.8 tons / m3 (g / cm3) antirust aluminum density: 2.73 tons / m3 (g / cm3)

- Q: Can the aluminum sheets be used for manufacturing furniture?

- Yes, aluminum sheets can certainly be used for manufacturing furniture. Aluminum is a lightweight and strong material, making it ideal for creating furniture that is both durable and easy to move around. Additionally, aluminum is resistant to corrosion, so it can withstand exposure to various environmental conditions. Moreover, aluminum sheets can be easily shaped and formed into different designs, allowing for versatility in furniture manufacturing. Overall, using aluminum sheets for furniture manufacturing can result in high-quality, stylish, and long-lasting pieces.

- Q: How do aluminum sheets perform in terms of dimensional stability?

- Aluminum sheets generally exhibit good dimensional stability due to their low coefficient of thermal expansion, meaning they are less likely to warp or deform when exposed to temperature changes compared to other materials.

- Q: What are the dimensions and thickness options for aluminum sheets?

- Depending on specific requirements and applications, the dimensions and thickness options for aluminum sheets can vary. There is a wide range of sizes and thicknesses available to cater to different needs. Concerning dimensions, aluminum sheets come in various widths and lengths, typically ranging from 36 inches to 72 inches in width and 96 inches to 144 inches in length. However, these dimensions may vary depending on the supplier and the specific product. The thickness options for aluminum sheets also differ. Thickness is usually measured in gauge, where lower gauge numbers indicate thicker sheets. Aluminum sheets can be obtained in various gauges, ranging from 0.006 inches (very thin) to 0.5 inches (thicker) or even thicker for specialized applications. It is important to note that the specific dimensions and thickness options may vary depending on the supplier and the grade of aluminum being used. It is always advisable to consult with a supplier or manufacturer to obtain precise information about the available dimensions and thickness options for aluminum sheets.

- Q: Can the export quality of China's aluminum plate meet the requirement of ASTM B 209? Is this requirement for our country? Master the exhibitions, O (a _ U) O thank you

- ASTM is the standard used in the United StatesEquivalent to China's GBGenerally equivalent to the use of Chinese standardsSpecific depends on whether the customer agreesIn fact, just do a testMeet its requirements

- Q: Are 101 aluminum sheets suitable for conductive heat transfer applications?

- No, 101 aluminum sheets are not suitable for conductive heat transfer applications as they do not have good thermal conductivity properties.

- Q: What are the distinctions among various grades of aluminum sheets?

- <p>Yes, there are differences between different grades of aluminum sheets. These differences are primarily based on the alloy composition, which affects properties such as strength, formability, and corrosion resistance. For instance, 1000 series aluminum is pure and soft, making it ideal for general purposes. 2000 series is harder and stronger, often used in aerospace applications. 3000 series is known for its high resistance to corrosion and is used in marine applications. 5000 series offers good strength-to-weight ratio and is used in structural applications. 6000 series is known for its strength and is used in construction and industrial applications. Each grade has specific uses based on its unique characteristics.</p>

- Q: This question asks for methods to protect aluminum sheets from rusting when exposed to outdoor conditions.

- <p>To prevent rusting of aluminum sheets in outdoor environments, it's crucial to understand that aluminum doesn't rust but forms a thin layer of aluminum oxide, which can darken the surface. To protect aluminum sheets, use protective coatings such as clear anodizing, which enhances the natural oxide layer, or apply a paint or powder coating. Regular cleaning and maintenance can also help in removing dirt and grime that can accelerate the oxidation process. Additionally, using stainless steel fasteners and avoiding contact with dissimilar metals can help prevent galvanic corrosion.</p>

Send your message to us

Embossed Aluminum Sheets as per American Standard ASTM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords