Fiberglass Mat Tissue - E-Glass Stitched Chopped Mat (450g/m2~900g/m2)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introductions

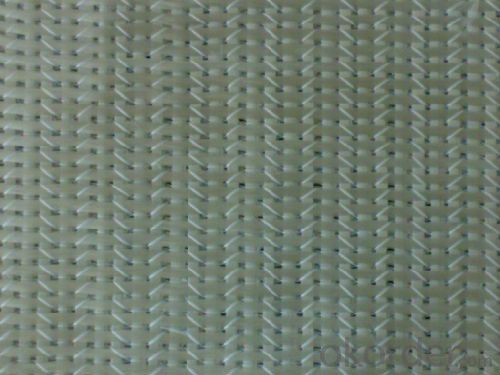

E-Glass Stitched Chopped Mat (450g/m2~900g/m2) is made by chopping continuous strands into chopped strands and stitching them together. The product has a maximum width of 110 inches. This product can be used in manufacturing boat manufacturing and tubes.

2.Product Features

Fast breakdown in styrene

Good wet-through and fast wet-out in resins, rapid air lease

Superior acid corrosion resistance

3.Product Specifications

Item | Over Density | Moisture Content | Chop Density | Polyester Yarn | Width |

(g/m2) | (%) | (g/m2) | (g/m2) | (mm) | |

EMK300 | 309.5 | ≤0.15 | 300 | 9.5 | 50-3300 |

EMK380 | 399 | 380 | 19 | ||

EMK450 | 459.5 | 450 | 9.5 | ||

EMK450 | 469 | 450 | 19 | ||

EMC0020 | 620.9 | 601.9 | 19 | ||

EMC0030 | 909.5 | 900 | 9.5 |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

E-Glass Stitched Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 76mm and the mat roll has a diameter of 275mm. The mat roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, E-Glass Stitched Chopped Strand Mat should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Can fiberglass mat tissue be used for reinforcing fiberglass roofs?

- Indeed, fiberglass mat tissue is a suitable option for reinforcing fiberglass roofs. Comprised of delicate fibers that are joined together using a binder, fiberglass mat tissue is a thin and lightweight material. It is widely utilized as a reinforcement layer in fiberglass composites, providing them with robustness and endurance. Concerning fiberglass roofs, fiberglass mat tissue can be applied as an extra layer to enhance the roof's structural integrity. This additional layer aids in evenly distributing the load across the surface, thereby augmenting the roof's resistance against cracks, leaks, and other types of damage. Typically, fiberglass mat tissue is used alongside other fiberglass products, including resin and fiberglass cloth, to generate a sturdy composite material. The mat tissue is placed atop the fiberglass cloth prior to the application of resin. Subsequently, the resin saturates the mat tissue, establishing a bond between the layers. This combination results in a reinforced fiberglass roof that possesses heightened strength and durability. Moreover, fiberglass mat tissue can confer thermal insulation properties to the roof, contributing to temperature regulation and reduced energy consumption. It exhibits resistance against heat transfer, thereby preventing excessive heat accumulation within the building during hot weather. All in all, fiberglass mat tissue is an exceptional choice for reinforcing fiberglass roofs. By adding strength, durability, and thermal insulation properties to the roof, it becomes a reliable option for both residential and commercial buildings.

- Q: Does fiberglass mat tissue require any special handling precautions?

- Yes, fiberglass mat tissue does require special handling precautions. Due to its nature, fiberglass mat tissue can release tiny glass fibers into the air when handled incorrectly. These fibers can cause skin irritation, eye irritation, and respiratory issues if inhaled. Therefore, it is important to wear appropriate protective clothing, such as gloves, long-sleeved shirts, pants, and safety goggles, when handling fiberglass mat tissue. It is also advisable to work in a well-ventilated area or use respiratory protection if working in a confined space. Additionally, it is crucial to handle the material gently to avoid any breakage or damage that could release more fibers into the environment. Proper disposal methods should also be followed to prevent any potential harm. Overall, taking these precautions ensures the safety and well-being of individuals handling fiberglass mat tissue.

- Q: What are the advantages of using fiberglass mat tissue?

- The advantages of using fiberglass mat tissue include its high strength-to-weight ratio, excellent dimensional stability, resistance to corrosion, and ability to provide reinforcement to various materials. Additionally, fiberglass mat tissue is easy to handle and can be easily molded or shaped to fit different applications, making it a versatile choice in industries such as construction, automotive, and aerospace.

- Q: Does fiberglass mat tissue require any special curing conditions?

- Typically, there are no special curing conditions needed for fiberglass mat tissue. It can be cured at room temperature, eliminating the need for high temperatures or specific curing environments. The process involves applying resin to the tissue, which gradually hardens and forms a bond with the fibers. This curing can naturally take place at room temperature or can be expedited through the use of heat or catalysts. Nonetheless, it is crucial to adhere to the manufacturer's instructions and recommendations for the particular type of fiberglass mat tissue being utilized, as certain variations may have unique curing demands.

- Q: Can fiberglass mat tissue be used for boat building?

- Yes, fiberglass mat tissue can be used for boat building. It is commonly used as a reinforcement material in boat construction due to its strength, durability, and ability to resist water damage.

- Q: How is fiberglass mat tissue used in the production of storage sheds?

- The production of storage sheds commonly utilizes fiberglass mat tissue due to its exceptional strength and durability. This material is typically employed as a reinforcement to enhance the structural integrity of the shed's walls, roof, and floor. During manufacturing, fiberglass mat tissue is frequently applied to both the exterior and interior surfaces of the shed. It is initially impregnated with a binding resin, usually polyester or epoxy. The resin-soaked fiberglass mat tissue is then layered onto the shed's panels or molds. Once in position, the resin is cured, either through heat application or a chemical reaction, which solidifies the material. This process creates a rigid, lightweight composite structure that is highly resistant to cracking, warping, and rotting, as well as being weather-resistant. The fiberglass mat tissue acts as a reinforcing layer, providing additional strength and stability to the shed. It helps evenly distribute loads across the structure, making it more resistant to impacts and external forces. Additionally, it prevents the shedding of particles, enhancing the overall appearance and cleanliness of the shed. Moreover, fiberglass mat tissue offers excellent thermal insulation. This insulation helps regulate the shed's temperature, keeping it cool in the summer and warm in the colder months. It also reduces energy costs by minimizing heat transfer. In conclusion, the inclusion of fiberglass mat tissue significantly improves the durability, strength, and insulation capabilities of storage sheds. It ensures a long-lasting and reliable structure that can withstand various weather conditions while providing a comfortable and secure storage space.

- Q: Is fiberglass mat tissue suitable for electrical insulation applications?

- Yes, fiberglass mat tissue is suitable for electrical insulation applications. Fiberglass mat tissue is made from glass fibers that are bonded together with a resin, creating a strong and durable material. It has excellent electrical insulation properties, such as high dielectric strength and low electrical conductivity. This makes it ideal for applications where electrical insulation is required, such as in transformers, motors, and electrical switchgear. Additionally, fiberglass mat tissue is also resistant to moisture, chemicals, and heat, further enhancing its suitability for electrical insulation applications.

- Q: Does fiberglass mat tissue provide any sound insulation?

- Yes, fiberglass mat tissue does provide sound insulation. It is a common material used in various industries, including construction and automotive, to absorb and reduce sound transmission. The fibrous structure of the material helps to trap and absorb sound waves, preventing them from passing through walls or other surfaces. Fiberglass mat tissue is often used as an acoustic insulation material in walls, floors, and ceilings to create a more comfortable and noise-free environment.

- Q: What are the properties of fiberglass mat tissue?

- Fiberglass mat tissue, also referred to as fiberglass mat or fiberglass matting, is a non-woven material made from glass fibers, possessing numerous properties that render it suitable for diverse applications. 1. With regards to strength and durability, fiberglass mat tissue is renowned for its high tensile strength, enabling it to endure substantial stress without fracturing. This quality makes it ideal for fortifying and reinforcing various materials and structures. 2. Despite its strength, fiberglass mat tissue remains relatively lightweight, facilitating easy handling and transportation. This characteristic proves particularly advantageous in industries where weight reduction plays a crucial role, such as aerospace and automotive. 3. The flexibility of fiberglass mat tissue allows it to conform to curved surfaces and intricate shapes. Consequently, it proves versatile and appropriate for applications requiring the material to be molded or shaped into specific designs. 4. Fiberglass mat tissue exhibits excellent resistance to various chemicals, including acids, alkalis, and most solvents. This attribute renders it suitable for use in corrosive environments, such as chemical processing plants or storage tanks. 5. Fiberglass mat tissue possesses commendable thermal insulation properties, effectively reducing heat transfer. Consequently, it proves valuable in applications necessitating heat insulation, such as the construction of walls, roofs, or insulation boards. 6. Inherently fire-resistant, fiberglass mat tissue does not contribute to the propagation of flames. As a result, it finds extensive use in applications where fire safety is paramount, such as the production of fire-resistant doors, panels, or insulation materials. 7. Furthermore, fiberglass mat tissue offers excellent sound insulation properties, diminishing the transmission of noise through walls or other structures. This characteristic renders it suitable for implementation in soundproofing applications, such as recording studios or automotive interior panels. Overall, the properties exhibited by fiberglass mat tissue endow it with versatility, allowing for a wide range of applications across various industries, including construction, automotive, aerospace, and marine. Its strength, flexibility, lightweight nature, chemical resistance, thermal and sound insulation properties, as well as its fire resistance, contribute to its popularity and usefulness in numerous applications.

- Q: Can fiberglass mat tissue be used for attic insulation?

- Fiberglass mat tissue is not typically used as a primary insulation material for attics. While it does offer some thermal resistance, it is generally designed to be used in conjunction with other insulation materials, such as fiberglass batts or blown-in insulation, to enhance their performance. Fiberglass mat tissue is often used as a facing material for insulation products, serving as a vapor barrier or as a reinforcement layer. It can help improve the durability and moisture resistance of the insulation, but its main purpose is not to provide significant thermal insulation on its own. When insulating an attic, it is more common to use materials specifically designed for thermal insulation, such as fiberglass batts, cellulose, or spray foam insulation. These materials have higher R-values and are more effective at reducing heat transfer, which is crucial for maintaining a comfortable indoor temperature and energy efficiency. In summary, while fiberglass mat tissue may have some insulating properties, its primary role is to enhance the performance of other insulation materials rather than being used as the sole insulation for an attic.

Send your message to us

Fiberglass Mat Tissue - E-Glass Stitched Chopped Mat (450g/m2~900g/m2)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords