E-glass Fiberglass Woven Roving,270g,1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

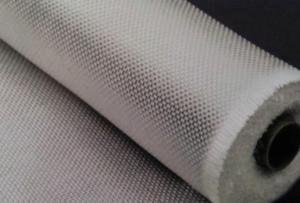

Structure of woven roving Description

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

Application of Fiberglass Woven Roving:

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyeser,vinylester and epoxy resins

- Q: How long does fiberglass mat tissue last?

- The lifespan of fiberglass mat tissue varies depending on various factors such as the quality of the material, environmental conditions, and maintenance. However, on average, fiberglass mat tissue can last for several decades if properly installed and cared for.

- Q: Are there any environmental considerations when using fiberglass mat tissue?

- Yes, there are several environmental considerations when using fiberglass mat tissue. Firstly, the production of fiberglass mat tissue involves the use of energy and resources. The manufacturing process requires the extraction of raw materials, such as silica sand, limestone, and soda ash, which are non-renewable resources. The energy-intensive process of melting these materials at high temperatures also contributes to greenhouse gas emissions. Additionally, the production of fiberglass involves the use of chemicals, such as resins and binders, which can be harmful to the environment if not properly managed. These chemicals can potentially leach into water bodies or soil if not handled and disposed of correctly. Furthermore, fiberglass mat tissue is not biodegradable. Once it reaches the end of its lifespan, it can take hundreds of years to break down in a landfill. Improper disposal of fiberglass mat tissue can lead to environmental pollution and contribute to the growing problem of waste management. Lastly, the use of fiberglass mat tissue in certain applications, such as insulation or construction, can have energy efficiency implications. While fiberglass is an effective insulator, its production and installation may require additional energy inputs, such as the use of fossil fuels for transportation or heating during installation. To mitigate these environmental considerations, it is important to promote sustainable practices in the production and use of fiberglass mat tissue. This can include implementing energy-efficient manufacturing processes, reducing the use of harmful chemicals, promoting recycling or reuse of fiberglass materials, and exploring alternative materials that have a lower environmental impact.

- Q: How does fiberglass mat tissue perform in terms of thermal conductivity?

- Fiberglass mat tissue has low thermal conductivity, meaning it is a poor conductor of heat.

- Q: Can fiberglass mat tissue be used for insulating windows?

- Yes, fiberglass mat tissue can be used for insulating windows. Fiberglass mat tissue is a lightweight and flexible material that is commonly used for insulation purposes. It has high thermal resistance and is capable of reducing heat loss or gain through windows. By placing a layer of fiberglass mat tissue on the window surface, it can help to improve the insulation properties of the window, reducing drafts and heat transfer. Additionally, fiberglass mat tissue is also effective in reducing noise transmission through windows, making it a versatile option for both thermal and acoustic insulation.

- Q: Can fiberglass mat tissue be used for insulation in pharmaceutical storage areas?

- Yes, fiberglass mat tissue can be used for insulation in pharmaceutical storage areas. Fiberglass mat tissue is a versatile material that offers excellent thermal insulation properties. It is often used in various industries, including pharmaceuticals, due to its ability to regulate temperature and provide insulation against heat transfer. In pharmaceutical storage areas, maintaining the appropriate temperature is crucial to ensure the integrity and stability of stored medications and vaccines. Fiberglass mat tissue can help create a temperature-controlled environment by reducing heat transfer between different areas and protecting the stored products from external temperature fluctuations. Additionally, fiberglass mat tissue is lightweight, easy to install, and resistant to moisture, making it suitable for pharmaceutical storage areas where cleanliness and hygiene are essential. It can be easily placed between walls, ceilings, and floors to provide a barrier against heat flow, thus maintaining the desired temperature inside the storage area. Moreover, fiberglass mat tissue is a non-combustible material, which adds an extra layer of safety in pharmaceutical storage areas. It does not contribute to the spread of fire, ensuring the protection of valuable pharmaceutical products and reducing the risk of fire-related accidents. Overall, fiberglass mat tissue is an effective choice for insulation in pharmaceutical storage areas, providing thermal regulation, moisture resistance, cleanliness, and fire safety. It helps maintain the required temperature and ensures the integrity and stability of stored medications and vaccines.

- Q: Is fiberglass mat tissue resistant to solvents?

- Yes, fiberglass mat tissue is generally resistant to solvents.

- Q: Can fiberglass mat tissue be used for repairing fiberglass bathtubs?

- Yes, fiberglass mat tissue can be used for repairing fiberglass bathtubs. Fiberglass mat tissue is a thin, flexible material that is used for reinforcing and strengthening fiberglass surfaces. It is commonly used in the repair and restoration of fiberglass products, including bathtubs. The mat tissue is typically applied over the damaged area, along with a layer of resin, to create a strong and durable repair. The mat tissue helps to reinforce the weakened or damaged areas of the bathtub, restoring its integrity and preventing further damage. However, it is important to note that the success of the repair will depend on the extent of the damage and the skill of the person performing the repair. It is recommended to consult a professional or follow manufacturer's instructions for the best results.

- Q: Can fiberglass mat tissue be used for repairing fiberglass tanks?

- Yes, fiberglass mat tissue can be used for repairing fiberglass tanks. Fiberglass mat tissue is a thin, flexible material that is commonly used in the construction and repair of fiberglass products. It is designed to provide reinforcement and strength to the repaired areas. When applied with an appropriate resin, fiberglass mat tissue can effectively repair cracks, holes, or damaged sections of fiberglass tanks. However, it is important to ensure that the repair is done in a proper and professional manner, following the manufacturer's instructions and guidelines. Additionally, it is recommended to consult with an expert or specialist in fiberglass repair to ensure the best possible outcome for the repair.

- Q: How does fiberglass mat tissue compare to spray foam insulation?

- Fiberglass mat tissue and spray foam insulation are two different types of insulation materials with their own unique characteristics and benefits. Fiberglass mat tissue is a type of insulation made from woven strands of fiberglass. It is typically used in applications where thermal insulation is required, such as in walls, roofs, and attics. Fiberglass mat tissue is known for its high resistance to heat transfer, making it an effective insulator. It is also fire-resistant, which adds an additional safety benefit. On the other hand, spray foam insulation is a type of insulation that is applied as a liquid and expands into a solid foam. It can fill in small cracks and gaps, creating an airtight seal, which makes it an excellent choice for preventing air leakage and reducing energy loss. Spray foam insulation is also known for its excellent soundproofing qualities. In terms of installation, fiberglass mat tissue usually comes in large rolls or batts that need to be cut and fitted into place. It requires careful handling to ensure proper installation and may require the use of protective equipment, such as gloves and masks, as the fibers can cause skin and respiratory irritation. Spray foam insulation, on the other hand, is applied using specialized equipment that sprays the liquid foam onto the desired surface. It expands quickly, filling in any gaps or voids, and hardens within a short period of time. This makes it a more convenient option for insulating hard-to-reach areas or irregularly shaped spaces. When comparing the two, fiberglass mat tissue is generally more cost-effective, as it is less expensive to purchase and install compared to spray foam insulation. However, spray foam insulation provides better air sealing and can offer higher energy savings in the long run. In summary, fiberglass mat tissue and spray foam insulation have their own advantages and are suited for different insulation needs. Fiberglass mat tissue is a good option for thermal insulation, while spray foam insulation excels in air sealing and soundproofing. The choice between the two ultimately depends on factors such as budget, desired insulation performance, and the specific requirements of the project.

- Q: Is fiberglass mat tissue suitable for insulation in pharmaceutical plants?

- Yes, fiberglass mat tissue is suitable for insulation in pharmaceutical plants. It is a commonly used material in various industries, including pharmaceutical, due to its excellent thermal insulation properties and resistance to moisture, chemicals, and fire. Additionally, fiberglass mat tissue is lightweight, easy to install, and can help maintain controlled environments, making it an ideal choice for insulation in pharmaceutical plants where maintaining proper temperature and cleanliness is crucial.

Send your message to us

E-glass Fiberglass Woven Roving,270g,1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords