Dyed Rosewood Engineered Wood Veneers

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

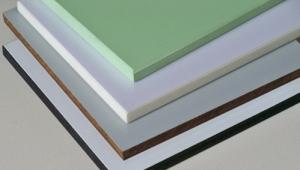

Specifications of the Rosewood Engineered Wood Veneer

| Length | 2150-3100mm |

| Width | 320-900mm |

| Thickness | 0.15-2mm |

| Normal size | 2500*640*0.5mm |

Instruction of the Rosewood Engineered wood Veneer

Engineered Veneer is a sliced reconstructed real wood veneer. It is made from natural timber

which color is enhanced, reformed to a square "log" and then re-sliced in rectangular veneer

sheets.

The usage of the Rosewood Engineered Wood Veneer

It is widly applid in the following regions: door inserts, wall panels, ceiling panels, privacy

screens, architectural millwork, and furniture inlays, hotel, shopping mall, restaurtant, loung,

commercial space, chains, office, halll dinning, expo, column, furniture,slide door, interior door,

house, bar etc.

Effects advantage of the Rosewood Engineeres Wood Veneer

Both retro style, yet stylish and elegant, more beautiful and noble, elegant fashion to create

different decorative effects, the majority of designers and high-taste people of all ages.

The following pictures are for reference:

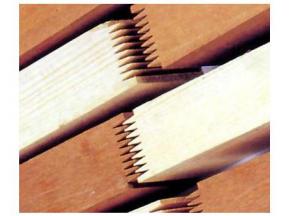

- Q: Often, the processing of natural vines is done by slicing the method. The process flow is as follows

- The program is reasonable not only the high rate of production, and the system is made of chopped thin wood, chord thin wood, the resulting high value of decorative products.

- Q: How to seize the key to solve the problem of slow development of paste veneer process?

- According to professional survey found that upgrading the veneer process not only to ensure the quality of veneer and production level, but also need a suitable veneer glue

- Q: The Veneer dyeing quality requirements

- Quality requirements: the color is not bleaching, the whole batch of goods not more than three kinds of color, flat, humidity does not exceed 10%, no residue of chemicals, no smell.

- Q: The following table lists the cooking criteria for several types of wood,

- intermittent operation of the drying room. Drying room is old-fashioned drying equipment, very economical, but dry quality is better.

- Q: What can the veneer be classified?

- according to the manufacturing method of classification Can be divided into sliced thin wood; peeling veneer; sawing thin wood; semi-circular peeling veneer. Often the use of slicing method

- Q: Brief description of veneer production process

- so as to avoid the thermal stress caused by wood cracking. The cooking pool should often clear the resin, bark, sediment, and often change the water, to reduce the pollution of the wood

- Q: Different veneer has different production processes

- Most furniture companies believe that science and technology veneer is not a native wood, but what is it, they also do not know, or simply called "artificial veneer".

- Q: Veneer has a very affordable, versatile features

- a short period of time some of the tree species by artificial cultivation is impossible, although the market now has a lot of technology veneer,

- Q: Different cutting processes of wood veneer

- in 1965 in Italy and the United Kingdom have launched the earliest, domestic generally called" science and technology.

- Q: What are the quality items of veneer piles?

- said sapwood. In the medullary around the material color deep, less water part, said the heartwood

Send your message to us

Dyed Rosewood Engineered Wood Veneers

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 SQM m²

- Supply Capability:

- 200000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords