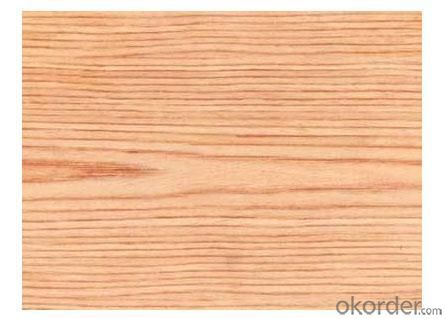

Exotic Wood Veneers - Natural Red Oak Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of the natural red oak veneer

| Veneer size | 2200-3000*130+0.5 |

| Grade | A, B,C |

| Applications | furniture making, interior and exterior decoration |

| Species | red oak |

| Packing | standard exporting packing |

The advantages of the natural red oak veneer

A) high quality of the natural red oak veneer, no sound and dead knot, no hole and very clean

B) professtional team for your whole exporting process

C) moisture: to be 8-10% at time of shippment

D) various species and various colors to meet your requirements

E) the natural red oak veneer can make the furniture appear especially high grade

F) applied in the modern design and traditional classic design

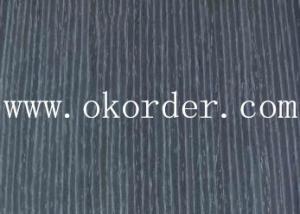

other wood species for the natural veneer

White oak, teak, russian oak, sapeli, russian birch, american walnut, maple, cherry.

Application of the natural red oak veneer

The cutting style of the natural red oak veneer is sliced or rotary cut, it is widly used in the furniture

making, interior and exterior decoration. Especially for face or back-fancy plywood, flooring. It is

stable supply for both crown and quarter.

The following pictures for reference

- Q: Simple construction method of veneer

- . In order to paste the veneer, the optional paint for paint, make it bright or hyperchromic.

- Q: Advantages and disadvantages of Technology veneer and natural veneer

- Let's talk about natural veneer. Natural veneer regardless of pattern or texture than the wood to do the effect of furniture

- Q: Often, the processing of natural vines is done by slicing the method. The process flow is as follows

- The use of these saws to produce veneer, the board rate is high, the quality of thin wood is better, chopper machine is more efficient.

- Q: The following table lists the cooking criteria for several types of wood,

- intermittent operation of the drying room. Drying room is old-fashioned drying equipment, very economical, but dry quality is better.

- Q: Technology veneer and natural veneer distinction

- And now the technology veneer manufacturers are constantly improving the natural sense of science and technology veneer

- Q: Often, the processing of natural vines is done by slicing the method.

- Different diameter logs should use different sawing programs. The thick lines in the figure are the saw lines, and the direction of the arrows is the planing direction of the planer

- Q: Different veneer has different production processes

- and in the production of a large number of applications, access to a huge economic benefits

- Q: Veneer should pay attention to the different production processes

- First of all, in our country will be used for wood veneer furniture, veneer materials, furniture manufacturing enterprises More and more,

- Q: Different cutting processes of wood veneer

- Technology wood mainly to natural ordinary wood or artificial Planted fast-growing forest as raw material, processed and processed, and natural precious veneer similar ...

- Q: What are the specifications for veneer?

- The price is usually longer and more expensive. The thickness of the thinest 15 silk, thick more than one hundred silk

Send your message to us

Exotic Wood Veneers - Natural Red Oak Veneer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000000 SQM/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords