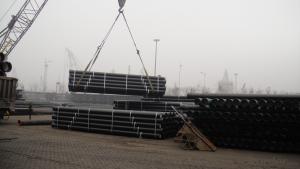

Ductile Iron Pipe For Water Project From China On Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Place of Origin: China (Mainland)

Model Number: T type / K type / Flange type

Length: 6M/NEGOTIATED

Standard: ISO2531 and EN545

Application: Potable/Sewage Water

Diameter: DN80~DN1600

Shape: Round

Hardness: 230

Pipe Wall Thickness: STANDARD

Pull Strength: 420 Yield (≥ MPa): 300

Material: Cast Iron

Type: Ductile Iron Pipes

Certification: ISO2531 and EN545

Specification: DN80~DN1600

Outer Diameter: 80-1600

Thickness: standard

Usage: water pipe Packaging & Delivery

Packaging Details: DN80~DN300 are bundled with steel belts, others are in bulk condition.

Specification& Payment terms

Internal lining: Pipes shall have an internal cement mortar lining in acc with ISO4179.

External coating: Pipes shall be externally coated with metallic zinc spray plus a further layer of resin painting to ISO8179.

Gasket: 100% SBR/NBR/EPDM rubber gasket in accordance with ISO4633.

Packing: Pipes from DN100 to DN300 be bundled with steel belts, others are in bulk.

Payment term: L/C, T/T.

Packing: In bulk vessel or in container.

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: Can ductile iron pipes be used in nuclear power plants?

- Yes, ductile iron pipes can be used in certain applications within nuclear power plants. However, their use is limited to non-safety-related systems where they are not exposed to radioactive environments or high-pressure conditions. Safety-related systems within nuclear power plants typically require materials with higher resistance to radiation and pressure, such as stainless steel or other specialized alloys.

- Q: Can ductile iron pipes be used for water distribution networks?

- Yes, ductile iron pipes can be used for water distribution networks. Ductile iron pipes are highly durable, corrosion-resistant, and have a long lifespan, making them suitable for transporting water over long distances. Additionally, their flexible nature allows them to withstand ground movement and vibrations, making them a reliable choice for water distribution networks.

- Q: How does ductile iron pipe perform in high-temperature steam applications?

- In high-temperature steam applications, ductile iron pipe performs admirably. Ductile iron, renowned for its strength and durability, possesses the capability to endure high pressures and temperatures. When subjected to high-temperature steam, ductile iron pipes retain their structural integrity and are not easily deformed or cracked. They possess a remarkable resistance to thermal expansion and contraction, rendering them suitable for situations where temperature fluctuations are common. Furthermore, ductile iron pipes exhibit exceptional corrosion resistance, a crucial characteristic in steam applications where the presence of moisture can accelerate corrosion. All in all, ductile iron pipes are a dependable choice for high-temperature steam applications, delivering enduring performance and ensuring the secure and efficient transportation of steam.

- Q: What are the requirements for the hydrostatic test of ductile iron pipes?

- Hydraulic test of pipeline segment length should not be more than 1 kilometers, the test pipe should be in full of water, no pressure under the condition of full immersion, soaking time of ductile cast iron pipe without mortar lining not less than 24 hours, a mortar lining the immersion of not less than 48 hours.

- Q: How does ductile iron pipe perform in seismic areas?

- Ductile iron pipe performs exceptionally well in seismic areas due to its inherent strength and flexibility. Seismic activity can subject pipelines to significant ground movements and vibrations, and ductile iron pipes have proven to be highly resilient in such conditions. The unique properties of ductile iron, including its high tensile strength and ductility, allow it to absorb the energy generated during seismic events. This ability to flex and bend without breaking or fracturing makes it an excellent choice for areas prone to earthquakes. Furthermore, ductile iron pipes are designed and manufactured to withstand external forces and ground movements. They are often installed with flexible joints that can accommodate ground shifts and maintain the integrity of the pipeline system. These joints can absorb lateral and angular movements, reducing the risk of pipe failure. Additionally, ductile iron pipes have a long history of successful performance in seismic areas. They have been extensively tested and proven to meet or exceed industry standards for seismic resistance. This reliability is crucial in ensuring the safety and functionality of water and wastewater systems, even in the event of a seismic event. Overall, ductile iron pipe is a reliable and durable choice for pipelines in seismic areas. Its ability to withstand ground movements, its flexibility, and its proven track record make it an excellent option for ensuring the integrity and functionality of water and wastewater systems in earthquake-prone regions.

- Q: Are ductile iron pipes suitable for use in irrigation sprinkler systems?

- Yes, ductile iron pipes are suitable for use in irrigation sprinkler systems. Ductile iron pipes are known for their strength, durability, and corrosion resistance, making them an ideal choice for transporting water in irrigation systems. They can withstand high pressure and provide long-term reliability, ensuring efficient water distribution for irrigation purposes.

- Q: What are the different methods for anchoring ductile iron pipe?

- There are several methods available for anchoring ductile iron pipe, depending on the specific application and requirements. 1. Thrust Blocks: This method involves constructing concrete blocks around the pipe at points where there are changes in direction or changes in pipe diameter. The blocks provide resistance against the thrust forces generated by the flowing water, preventing movement of the pipe. 2. Concrete Collars: Concrete collars or rings can be installed around the pipe at regular intervals to provide additional support and prevent lateral movement. These collars are typically made by pouring concrete into a pre-made mold around the pipe. 3. Pipe Clamps: Pipe clamps are metal brackets that can be attached to the pipe and anchored to a structure or a support system. These clamps come in various sizes and designs, providing flexibility in installation and allowing for adjustment as needed. 4. Pipe Restraints: Pipe restraints are devices specifically designed to restrain the movement of ductile iron pipe. They usually consist of a metal band or collar that is tightened around the pipe and attached to a concrete structure or an anchoring system. 5. Bell and Spigot Joint: The bell and spigot joint itself can act as a means of anchoring the pipe. The bell end of one pipe fits over the spigot end of another, creating a tight connection that helps resist movement. 6. Soil Embedment: Properly compacted soil surrounding the pipe can provide some level of anchoring. The soil should be compacted in layers around the pipe to ensure stability and prevent movement. It is important to note that the selection of the anchoring method depends on factors such as soil conditions, pipe diameter, operating pressure, and location. Consulting industry standards and guidelines, along with the assistance of a qualified engineer, is crucial in determining the appropriate anchoring method for a specific ductile iron pipe installation.

- Q: How are ductile iron pipes transported and stored?

- To ensure the safety and integrity of ductile iron pipes, a systematic and cautious approach is taken during their transportation and storage. Typically, specialized vehicles such as flatbed trucks or trailers are used to transport ductile iron pipes. These vehicles are specifically designed to accommodate the size and weight of the pipes. They are equipped with securing mechanisms that effectively prevent any movement or damage during transit. Forklifts or cranes are used to load the pipes onto the vehicles, ensuring proper support and balance to prevent bending or deformation. To protect the pipes from external factors that may cause damage, measures are taken during transportation. Covers or wraps are placed over the pipes to shield them from adverse weather conditions such as rain, snow, or excessive sunlight. Straps or chains are also used to secure the pipes, preventing any shifting or rolling during transit. During storage, ductile iron pipes are stacked horizontally on specially designed racks or supports. This ensures even weight distribution and minimizes the risk of deformation or stress on the pipes. The storage area must be clean, dry, and well-ventilated to prevent corrosion or deterioration. It is crucial to handle ductile iron pipes with care to avoid impact or rough handling that could result in cracks or fractures. Workers involved in the transportation and storage process must receive proper training to ensure they adhere to protocols and use the necessary equipment, including lifting machinery and protective gear. Regular inspections of transported and stored ductile iron pipes are necessary to identify any signs of damage or corrosion. This allows for timely repairs or replacements, preventing any issues when the pipes are installed for their intended use. In conclusion, the transportation and storage of ductile iron pipes necessitate meticulous planning, appropriate equipment, and adherence to safety protocols to maintain their condition and performance.

- Q: What is the expected bending stress capacity of ductile iron pipes?

- The expected bending stress capacity of ductile iron pipes can vary depending on various factors such as the pipe's diameter, wall thickness, and the specific grade of ductile iron used. However, generally speaking, ductile iron pipes have a high bending stress capacity compared to other pipe materials. Ductile iron pipes are known for their high tensile strength and flexibility, making them capable of withstanding significant bending stresses. The exact bending stress capacity can be determined through rigorous testing and analysis by considering factors like the pipe's mechanical properties, dimensions, and the maximum allowable deflection. It is important to note that the bending stress capacity of ductile iron pipes should be evaluated in accordance with industry standards and guidelines. These may include standards such as the American Water Works Association (AWWA) C150 or International Organization for Standardization (ISO) 2531, which provide specifications and testing methods for ductile iron pipes. Ultimately, the expected bending stress capacity of ductile iron pipes is determined by several factors and should be assessed based on the specific requirements of the application, considering industry standards and guidelines for accurate and reliable results.

- Q: Which is good for water polo cast iron pipe steel pipe?

- In summary, if the demand is not high, the use of stable environment, pressure and vibration is not a place recommend the use of ductile iron pipe; if is an important facility for high requirements or site conditions, abnormal conditions, vibration and impact may be relatively large, with ordinary seamless steel tube.

Send your message to us

Ductile Iron Pipe For Water Project From China On Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords