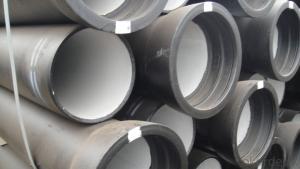

Ductile Iron Pipe ISO2531:1998 DN900 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 999 m

- Supply Capability:

- 9999 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Ductile Iron Pipe Description :

1) we can do third party inspection according to customer's request.

2)Our products have been sold to many international market, such as Middle East and South East Asia and Africa.

3)Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

4)Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets accoding to ISO4633

2,Main Features of the Ductile Iron Pipe:

1. Material: Ductile iron grade 500-7/ 450-10 in accordance with ISO1083

2. Standard: ISO 2531, EN545, EN598, ANSI, AWWA

3. Certificate: ISO9001, ISO14001, SGS, NSF, WRAS

4. Test: In accordance with ISO 2531 / EN 545 / EN598 and 100% water pressure test

5. Length: 6m or cut into 5.6m, 5.7m, 5.8m

6. Internal Lining: Cement, conform to ISO4179

7. External coating: Zinc + Bitumen, conform to ISO8179

8. Rubber: NBR, SBR, EPDM according to ISO4633 / EN681.1

9. Note: The gaskets, bolts & nuts are supplied respectively as your special requirement

3,Ductile Iron Pipe Images:

4. Ductile Iron Pipe Specification

Standard: API SPEC 5L 44th eidtion,ASTM A252-98(2007)

Grade: A53 Grades A/B, ASTM A106 Grades B/C,ASTM A179

AWWA, C200, ASTM A139, ASTM A120, API 5L Grade B

X42, X52, X56, X60, X65, X70, X80, X100

Weld Alternatives: LSAW

OD size range: 6.4~44.5mm

Wall thickness: 406.4~1422mm

Length: 3 - 12 m according to requirment

Note: Other grade can also be provided after consulting. Special design are available

for coal slurry conveyance LSAW line tube -- Service

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: Are ductile iron pipes suitable for horizontal auger boring installations?

- Yes, ductile iron pipes are suitable for horizontal auger boring installations. Ductile iron pipes have excellent strength and durability, making them ideal for underground installations. They can withstand the lateral forces and vibrations involved in auger boring, ensuring a reliable and long-lasting pipeline system.

- Q: Can ductile iron pipes be repaired if they are damaged?

- Yes, ductile iron pipes can be repaired if they are damaged. The extent of the damage will determine the type of repair that is needed. In cases where the pipe is cracked or has small holes, a repair clamp or a stainless-steel sleeve can be used to seal the damaged area. These methods provide a temporary fix and allow for the flow of water to continue until a more permanent repair can be made. For more severe damage, such as large cracks or broken sections, a full replacement may be necessary. This involves cutting out the damaged section of the pipe and installing a new piece. This process requires specialized equipment and expertise, but it can effectively restore the functionality of the pipe. It is important to note that the repair of ductile iron pipes should be carried out by trained professionals who have experience in working with this type of material. This ensures that the repairs are done correctly and do not compromise the integrity and safety of the pipeline system. Regular inspection and maintenance of ductile iron pipes can help identify any potential issues early on and prevent extensive damage that may require replacement rather than repair.

- Q: Maximum pipe diameter of ductile iron pipe

- The maximum diameter of ball milling cast iron pipe can be DN3000.. For long pressure pipeline, the performance of ball milling cast iron pipe is better than that of PCCP tube, and the performance is reliable, safe and stable!

- Q: Ductile iron pipe converter, steel transition DN100 turn 100, what is the specific accessories name? Can you supply photos?

- Plastic steel conversion parts performance description: long name high density polyethylene is mainly used for buried water supply and gas transmission pipeline links, can effectively and closely linked pipe port, quality assurance, reasonable price and price.

- Q: Are ductile iron pipes resistant to abrasion?

- Yes, ductile iron pipes are highly resistant to abrasion.

- Q: Can ductile iron pipes be used for geothermal energy systems?

- Yes, ductile iron pipes can be used for geothermal energy systems. Ductile iron pipes are known for their strength, durability, and resistance to corrosion, making them suitable for various applications, including geothermal energy systems. They can effectively handle the high pressures and temperatures associated with geothermal energy production, making them a reliable choice for transporting hot water or steam. Additionally, ductile iron pipes have a long lifespan, reducing maintenance and replacement costs for geothermal energy systems.

- Q: How does ductile iron pipe resist internal corrosion?

- Ductile iron pipe resists internal corrosion due to the protective barrier formed by its cement lining. This lining acts as a barrier between the iron pipe and the transported fluid, preventing direct contact and minimizing the chances of corrosion. Additionally, the high carbon content in ductile iron enhances its corrosion resistance compared to other types of iron pipes.

- Q: How does ductile iron pipe perform in areas with high groundwater salinity?

- Ductile iron pipe performs well in areas with high groundwater salinity due to its corrosion resistance properties. The iron pipe is coated with a protective layer that prevents corrosion and extends its lifespan, even in saline environments.

- Q: Can the sealing ring of ductile iron pipe be reused?

- The sealing ring is hard to install and take off. I have been in this line for six years. I haven't seen it removed. The rubber ring itself is not expensive. It is not necessary to reuse it.

- Q: Can ductile iron pipe be used for water well applications?

- Yes, ductile iron pipe can be used for water well applications. Ductile iron pipe is known for its strength and durability, making it suitable for various applications including water well systems. It has excellent corrosion resistance, which is crucial for water well applications where the pipe is constantly exposed to water and potential contaminants. Additionally, ductile iron pipe has the ability to withstand high pressure and external loads, making it a reliable choice for water well systems that require a strong and long-lasting pipe material.

Send your message to us

Ductile Iron Pipe ISO2531:1998 DN900 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 999 m

- Supply Capability:

- 9999 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords