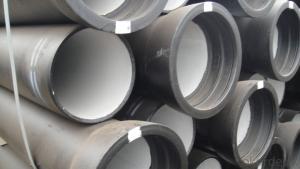

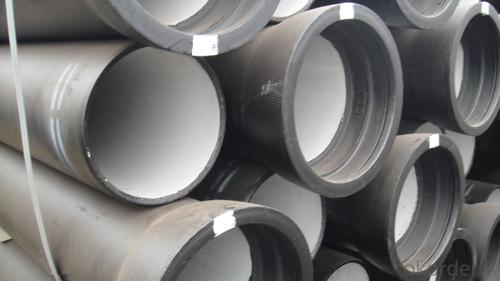

Ductile Iron Pipe K9 On Sale ISO2531/EN545

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Place of Origin: China (Mainland)

Model Number: T type / K type / Flange type

Length: 6M/5.8M/Negotiable

Standard: ISO2531/EN545 for portable and EN598 for sewer lines

Application: Potable/Sewage Water

Diameter: DN80~DN1600

Shape: Round

Hardness: 230

Pipe Wall Thickness: STANDARD

Pull Strength: 420 Yield (≥ MPa): 300

Material: Cast Iron

Type: Ductile Iron Pipes

Certification: ISO2531 and EN545

Specification: DN80~DN2600

Thickness: standard

Usage: water pipe Packaging & Delivery

Packing Details

Packaging Details: DN80~DN300 are bundled with steel belts, others are in bulk condition.

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: Are there any special coatings or linings used for ductile iron pipes?

- Yes, there are special coatings and linings used for ductile iron pipes. These coatings are applied to the interior and exterior surfaces of the pipes to protect them from corrosion and extend their lifespan. Common coatings include cement mortar lining, epoxy lining, and polyethylene encasement. These protective layers help prevent the formation of rust and scale, ensuring the durability and longevity of ductile iron pipes.

- Q: How do ductile iron pipes handle water hammer in high-rise buildings?

- Ductile iron pipes are well-suited to handle water hammer in high-rise buildings due to their inherent strength and durability. These pipes have the ability to withstand sudden changes in water flow and pressure, effectively reducing the impact of water hammer. Additionally, ductile iron pipes have excellent sound attenuation properties, which further minimizes the noise and vibrations caused by water hammer. Overall, ductile iron pipes offer reliable and long-lasting performance, making them an ideal choice for managing water hammer in high-rise buildings.

- Q: Can ductile iron pipe be used for industrial wastewater applications?

- Yes, ductile iron pipe can be used for industrial wastewater applications. Ductile iron pipe is known for its strength, durability, and resistance to corrosion, making it suitable for various applications including wastewater systems. It can handle high-pressure and heavy-duty environments, making it ideal for industrial wastewater applications that may involve abrasive or corrosive substances. Additionally, ductile iron pipe can be easily installed and maintained, reducing the overall costs and ensuring long-term reliability. However, it is important to consider the specific requirements of the wastewater application and consult with professionals to determine the most suitable pipe material and design.

- Q: What is the average weight of ductile iron pipes?

- The weight of ductile iron pipes can differ based on their specific dimensions and specifications. However, as a general rule, the weight of ductile iron pipes usually falls within the range of 50 to 200 pounds per foot. Various factors, including the pipe's diameter, wall thickness, and length, affect its weight. It is essential to understand that these weights are averages, and the actual weight of a particular ductile iron pipe may differ. To accurately determine the weight of a ductile iron pipe, it is recommended to consult the manufacturer's specifications or engineering guidelines.

- Q: What's the difference between grey cast iron pipe and ductile iron pipe?

- Ductile iron is close to medium carbon steel and is much cheaper. Vermicular graphite iron is the best, but grey iron is worse and white iron is the worst. Therefore, the quality of ductile iron pipe with better quality and price is superior to other cast iron pipe fittings.

- Q: What is the disadvantage of nodular cast iron in excess of silicon?

- Therefore, the increase of silicon content in nodular iron greatly improves the strength index and reduces toughness. Ductile iron has a greater crystalline undercooling and a tendency to chill when treated by spheroidizing, and silicon reduces this tendency.

- Q: Can ductile iron pipe be used for wastewater treatment plant sludge handling?

- Yes, ductile iron pipe can be used for wastewater treatment plant sludge handling. Ductile iron pipe is a strong and durable material that is resistant to corrosion and can withstand the harsh conditions associated with sludge handling. It is commonly used in wastewater treatment plants for conveying sludge, as it provides excellent structural integrity and has a long service life. Additionally, ductile iron pipe is easy to install and maintain, making it a practical choice for sludge handling applications in wastewater treatment plants.

- Q: Disadvantages of ductile iron pipes

- The strength of nodular cast iron is comparable to that of cast steel. Ductile iron has higher yield strength, the lowest yield strength is 40K, while the yield strength of cast steel is only 36k.

- Q: How many casting methods are there in ductile iron casting? A 60*6 discus can not have sand holes. Its surface is smooth. What process can be used to make it?

- Is it better to use precoated sand, but only a little higher cost?.

- Q: Will the quality of ductile iron shrink?

- This is a ductile iron is prone to problems, manhole covers, large flat pieces, you have to see clearly, and some appear to be concave, not shrink, it may be caused by large gas emissions, not out

Send your message to us

Ductile Iron Pipe K9 On Sale ISO2531/EN545

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords