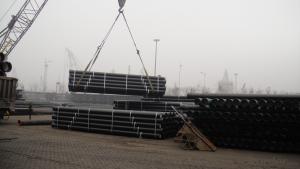

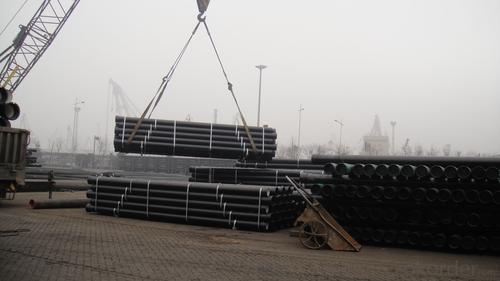

Ductile Iron Pipe For Water Project On Sale Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Place of Origin: China (Mainland)

Model Number: T type / K type / Flange type

Length: 6M/NEGOTIATED

Standard: ISO2531 and EN545

Application: Potable/Sewage Water

Diameter: DN80~DN1600

Shape: Round

Hardness: 230

Pipe Wall Thickness: STANDARD

Pull Strength: 420 Yield (≥ MPa): 300

Material: Cast Iron

Type: Ductile Iron Pipes

Certification: ISO2531 and EN545

Specification: DN80~DN1600

Outer Diameter: 80-1600

Thickness: standard

Usage: water pipe Packaging & Delivery

Packaging Details: DN80~DN300 are bundled with steel belts, others are in bulk condition.

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: What are the differences between ductile cast iron pipes and centrifugal ductile iron pipes?

- Centrifugal casting is a casting method. Ball milling cast iron pipe is a kind of material.

- Q: Are ductile iron pipes suitable for power plant cooling systems?

- Yes, ductile iron pipes are suitable for power plant cooling systems. Ductile iron pipes offer several advantages that make them ideal for such applications. Firstly, ductile iron is known for its high strength and durability, making it capable of withstanding the high pressure and heavy loads often associated with power plant cooling systems. Additionally, ductile iron pipes have excellent resistance to corrosion, which is crucial in an environment where water and other cooling fluids are constantly flowing. Furthermore, ductile iron pipes have good thermal conductivity, meaning they can efficiently transfer heat away from the power plant equipment, contributing to the overall cooling process. Lastly, ductile iron pipes are also cost-effective compared to other materials commonly used in power plant cooling systems, making them a practical choice for such applications. Overall, ductile iron pipes are a reliable and suitable option for power plant cooling systems due to their strength, corrosion resistance, thermal conductivity, and cost-effectiveness.

- Q: Are ductile iron pipes resistant to acid attacks?

- Yes, ductile iron pipes are generally resistant to acid attacks. Ductile iron is a type of cast iron that has been treated with magnesium to improve its strength and ductility. This treatment creates a more resistant material that can withstand corrosive environments, including acids. However, it is important to note that the level of resistance may vary depending on the specific acid and concentration involved. In highly corrosive environments, such as those with strong acids or high concentrations, additional protective measures such as lining or coating the pipes may be necessary. Additionally, regular inspection and maintenance are also important to ensure the long-term durability and resistance of ductile iron pipes.

- Q: How do ductile iron pipes handle ground settlement?

- Ductile iron pipes have the ability to withstand ground settlement due to their flexibility and resilience. The inherent ductility of the material allows the pipes to absorb and distribute the stress caused by ground movement, minimizing the risk of damage or failure. Additionally, the joints of ductile iron pipes are designed to provide flexibility, allowing for slight movement and accommodating ground settlement without compromising the integrity of the pipeline system.

- Q: What are the different methods for cutting ductile iron pipe?

- There are several different methods for cutting ductile iron pipe, depending on the specific requirements and constraints of the project. Some common methods include: 1. Manual Cutting: This method involves using a handheld saw or grinder with an abrasive cutting wheel to cut through the ductile iron pipe. It is a simple and relatively inexpensive method, but it can be labor-intensive and time-consuming for larger pipe sizes. 2. Mechanical Cutting: Mechanical cutting methods involve using specialized machinery to cut through the ductile iron pipe. This can include bandsaws, pipe cutters, or hydraulic cutting machines. These machines can provide faster and more precise cuts, especially for larger pipe sizes. However, they can be more expensive and require skilled operators. 3. Torch Cutting: Torch cutting, also known as oxyfuel cutting, involves using a torch to heat the ductile iron pipe and then introducing a high-pressure oxygen stream to create a chemical reaction that cuts through the metal. This method is effective for cutting thick-walled ductile iron pipe, but it can generate a significant amount of heat and sparks, requiring proper safety precautions. 4. Plasma Arc Cutting: Plasma arc cutting utilizes a high-velocity jet of ionized gas (plasma) to melt and cut through the ductile iron pipe. This method is ideal for cutting through thick-walled pipes where precision and efficiency are required. However, it can be more expensive and may require specialized equipment and training. 5. Waterjet Cutting: Waterjet cutting uses a high-pressure jet of water mixed with an abrasive material to cut through the ductile iron pipe. This method is highly precise and does not generate heat or sparks, making it suitable for cutting in sensitive environments. However, it can be slower and more expensive compared to other cutting methods. It is important to consider factors such as pipe size, project requirements, budget, and safety when selecting the appropriate method for cutting ductile iron pipe. Consulting with professionals or experts in the field can help determine the most suitable method for a specific project.

- Q: Do ductile iron pipes require external coatings or wraps?

- Yes, ductile iron pipes typically require external coatings or wraps for protection against corrosion and to extend their lifespan.

- Q: What is the expected corrosion protection system for ductile iron pipes?

- Typically, the expected corrosion protection system for ductile iron pipes involves a combination of external coatings, internal linings, and cathodic protection. To protect against corrosion, external coatings are applied to the pipe's exterior surface. These coatings, usually fusion-bonded epoxy, polyethylene, or polyurethane, act as a barrier against corrosion from soil, water, and chemicals. Furthermore, they play a crucial role in prolonging the pipe's lifespan. In order to safeguard against corrosion caused by the transported fluid, internal linings are applied to the pipe's interior surface. These linings, which can be made of cement mortar, epoxy, or polyurethane, provide a smooth and protective layer that prevents the formation of rust and scale. Cathodic protection is an electrochemical technique employed to shield ductile iron pipes from corrosion. It involves the utilization of sacrificial anodes or impressed current systems to generate a protective electrical current that counteracts the corrosion process. By employing this method, the formation of rust is prevented, thereby extending the pipe's longevity. It is important to acknowledge that the specific corrosion protection system for ductile iron pipes may differ depending on the application and environmental factors. To determine the appropriate corrosion protection system for a specific ductile iron pipe installation, consulting with corrosion experts and adhering to industry standards and guidelines is of utmost importance.

- Q: Do rigid cement cast iron pipes need cement piers?

- Ductile iron pipes mainly called centrifugal ductile iron pipe, it has the properties of nature, iron and steel, excellent corrosion resistance, good ductility, good sealing effect, simple installation, mainly for municipal, industrial and mining enterprises, water supply, gas, oil etc.. Water supply pipe is the first choice, with high cost performance. Compared with the PE pipe, from the installation time, ductile pipe PE pipe installation is simple and rapid, and after the installation of internal and external pressure bearing better tightness and corrosion resistance; from the point of view, ductile pipe sealing better after installation, but also can improve the corrosion resistance of corrosion protection through a variety of means; from the hydraulic performance, because ductile pipe specifications generally refers to the inner diameter of PE pipe diameter specifications generally refers to the same specifications, because under the condition of ductile pipe can achieve greater runoff; from the installation and maintenance cost, ductile pipe have more favorable price. The main components of ductile iron pipes are carbon, silicon, manganese, sulfur, phosphorus and magnesium. The inner wall of zinc spray, anti-corrosion materials such as cement mortar.

- Q: How do ductile iron pipes perform in high-temperature steam applications?

- Ductile iron pipes excel in high-temperature steam applications thanks to their remarkable performance. They can withstand elevated temperatures and maintain their structural integrity, making them highly suitable for steam distribution systems. One notable advantage of ductile iron pipes in high-temperature steam applications lies in their exceptional thermal conductivity. This property enables efficient heat transfer, ensuring that the steam is delivered at the desired temperature with minimal loss. Additionally, the high thermal conductivity of ductile iron helps to mitigate the risk of thermal expansion and contraction, which can lead to pipe failure or leakage. Moreover, ductile iron pipes boast a high melting point, typically around 2000°F (1093°C). This resistance to extreme temperatures encountered in steam applications ensures that the pipes remain intact and do not deform, guaranteeing the reliability and longevity of the piping system. Another crucial factor contributing to the performance of ductile iron pipes in high-temperature steam applications is their corrosion resistance. These pipes are usually coated with epoxy or other protective materials to prevent corrosion and maintain their structural integrity, even in aggressive steam environments. This corrosion resistance ensures that the pipes can endure harsh conditions and operate efficiently over an extended period. In conclusion, ductile iron pipes are an ideal choice for high-temperature steam applications due to their excellent thermal conductivity, high melting point, and corrosion resistance. These properties make them a reliable and long-lasting option for steam distribution systems, ensuring the safe and efficient transportation of steam at elevated temperatures.

- Q: What is the expected deflection capability of ductile iron pipes?

- The expected deflection capability of ductile iron pipes is typically quite high compared to other pipe materials. Ductile iron pipes have a flexible nature that allows them to withstand external loads and stresses without breaking or cracking. This flexibility enables the pipes to deflect under pressure, absorbing the force and redistributing it evenly along the pipe's length. The specific deflection capability of ductile iron pipes can vary depending on factors such as pipe diameter, wall thickness, and soil conditions. However, in general, ductile iron pipes can typically deflect up to 2% to 5% of their diameter without causing any significant damage or compromising their structural integrity. This deflection capability allows the pipes to adapt to ground movement, thermal expansion, and other external forces, making them highly resilient and reliable for various applications. It is important to note that the deflection capability of ductile iron pipes should be considered in conjunction with other design criteria, such as the depth of the pipe burial, trench width, and backfill material. Following proper installation practices and adhering to industry standards and specifications will ensure that the expected deflection capability of ductile iron pipes is optimized and maintained throughout their service life.

Send your message to us

Ductile Iron Pipe For Water Project On Sale Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords