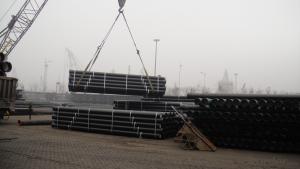

Ductile Iron Pipe For Water Project Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: What is the lifespan of ductile iron pipes?

- The durability and longevity of ductile iron pipes can vary depending on several factors, including pipe quality, installation conditions, and the surrounding environment. On average, these pipes typically last between 50 and 100 years, making them an excellent choice for water and sewer infrastructure. By implementing proper maintenance practices and conducting regular inspections, ductile iron pipes can remain highly functional and efficient for many decades. It should be noted that factors such as corrosion, soil conditions, and water chemistry can influence the lifespan of these pipes, so it is important to monitor and address these issues in order to extend their longevity.

- Q: Can ductile iron pipes be used for offshore oil and gas installations?

- Yes, ductile iron pipes can be used for offshore oil and gas installations. Ductile iron is known for its strength, durability, and corrosion resistance, making it suitable for various applications including offshore environments. Additionally, ductile iron pipes are cost-effective and can withstand high pressure and extreme weather conditions, making them a reliable choice for offshore oil and gas installations.

- Q: Can ductile iron pipes be used for industrial applications?

- Yes, ductile iron pipes can be used for industrial applications. Ductile iron is a type of cast iron that has significantly improved mechanical properties, including increased ductility and strength, compared to traditional cast iron. These qualities make ductile iron pipes highly suitable for industrial applications where durability, strength, and resistance to external forces are crucial. Industrial applications often involve high-pressure water or fluid transportation, and ductile iron pipes are designed to withstand such conditions. They have excellent tensile strength, which means they can resist deformation and fractures, making them ideal for handling heavy loads and withstanding significant internal and external pressures. Additionally, ductile iron pipes have excellent corrosion resistance properties, making them highly suitable for industrial applications where exposure to harsh chemicals or corrosive substances is common. Their resistance to corrosion ensures a longer service life and reduces maintenance costs associated with pipe replacement or repairs. Furthermore, ductile iron pipes are known for their versatility and adaptability. They can be easily connected and integrated into existing infrastructure, making them a preferred choice for industrial applications. Their high strength-to-weight ratio allows for easy handling and installation, which is essential in industrial settings. In conclusion, ductile iron pipes are suitable for industrial applications due to their improved mechanical properties, corrosion resistance, and versatility. Their ability to withstand high pressures, resist deformation, and adapt to existing infrastructure make them an excellent choice for various industrial applications.

- Q: What is the relationship between continuous cast iron pipe and ductile iron pipe?

- Continuous cast iron pipes are usually grey cast iron pipes. Its tensile strength and elongation are much lower than those of nodular cast iron. In chemical composition, grey cast iron has less carbon content than nodular cast iron. According to the organization, the graphite form of gray iron is flaky, and the graphite form in spheroidal graphite cast iron is spherical.

- Q: Are ductile iron pipes suitable for use in desalination plants?

- Yes, ductile iron pipes are suitable for use in desalination plants. Ductile iron is known for its high strength and durability, making it capable of withstanding the harsh conditions and corrosive nature of desalination processes. Additionally, ductile iron pipes have excellent resistance to internal and external corrosion, making them a reliable choice for transporting the high-pressure brine and freshwater in desalination plants.

- Q: How does ductile iron pipe perform in corrosive soils?

- Due to its inherent corrosion resistance properties, ductile iron pipe demonstrates exceptional performance in corrosive soils. This is attributed to its unique composition of iron, carbon, and other elements that enhance its durability and resistance to corrosion. A key feature of ductile iron pipe is its protective lining, which is either cement mortar or a special epoxy coating. This lining acts as a barrier between the corrosive soil and the pipe, preventing direct contact and corrosion. Furthermore, compared to other materials like steel, ductile iron pipe exhibits higher resistance to external corrosion. It can withstand the chemical reactions caused by acidic or alkaline soils and remains unaffected by the corrosive elements present in the ground. This quality makes it an ideal choice for installation in highly corrosive soil areas. Moreover, ductile iron pipe has a long service life, further contributing to its performance in corrosive soils. Its durability and resistance to corrosion ensure that it can withstand the challenges posed by corrosive soils for several decades without significant degradation. In conclusion, ductile iron pipe excels in corrosive soils due to its protective lining, resistance to external corrosion, and long service life. Its ability to withstand the harsh conditions presented by corrosive soils makes it a reliable and durable choice for various applications such as water distribution, sewage systems, and industrial pipelines.

- Q: Ductile iron and gray iron is what are the advantages and disadvantages of it

- Ductile iron with high strength, gray cast iron wear-resistant, vibration good.This is the reason why large quantities of grey iron are used as gear in imported vehicles.

- Q: What is the expected corrosion rate of ductile iron pipes?

- The expected corrosion rate of ductile iron pipes can vary depending on several factors, including the specific environment in which the pipes are installed, the pH and composition of the water or soil they come into contact with, and the presence of any corrosive substances or chemicals. In general, ductile iron pipes are known for their excellent resistance to corrosion compared to other materials such as cast iron or steel. This is due to the presence of a protective layer called a passive film, which forms naturally on the surface of the pipes when exposed to oxygen in the environment. This passive film acts as a barrier, preventing further corrosion from occurring. However, it is important to note that even ductile iron pipes can experience some level of corrosion over time, especially in aggressive or highly corrosive environments. The expected corrosion rate can range from very low to moderate, depending on the aforementioned factors. To ensure the longevity and performance of ductile iron pipes, it is recommended to implement proper maintenance and monitoring practices. This includes regular inspections, cleaning, and the application of protective coatings or linings when necessary. Additionally, implementing a cathodic protection system can further enhance the corrosion resistance of the pipes. Ultimately, it is important to consult with experts and professionals in the field of corrosion and pipe materials to accurately determine the expected corrosion rate of ductile iron pipes in a specific application or environment.

- Q: Classification of cast iron pipes

- Continuous cast iron straight pipe:Continuous cast iron pipe, namely continuous casting gray cast iron pipe, suitable for water and gas pressure fluid delivery.

- Q: What is the typical lifespan of ductile iron pipes?

- The typical lifespan of ductile iron pipes can vary depending on various factors such as the quality of the pipes, the environmental conditions, and the maintenance practices. However, on average, ductile iron pipes have a lifespan of around 75 to 100 years. This makes them a durable and long-lasting option for water and sewage transportation systems. With proper installation and regular maintenance, these pipes can withstand corrosion, pressure, and other external factors, ensuring their longevity and reliability. Additionally, advancements in coatings and linings have further enhanced the lifespan of ductile iron pipes, making them an excellent choice for infrastructural projects.

Send your message to us

Ductile Iron Pipe For Water Project Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords