Ductile Iron Manhole Cover of High Quality Made in China

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 170 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

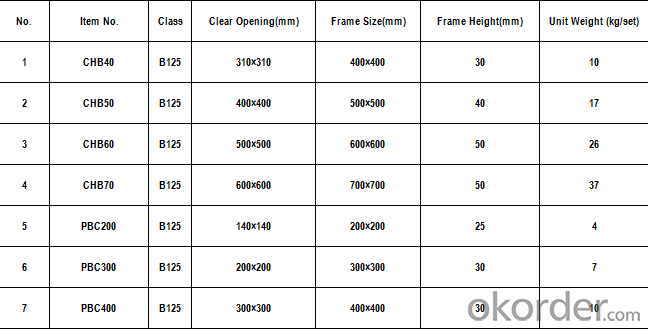

Specification

Product Information:

Manhole Covers are manufactured for construction and public use. Manhole Covers shall be smooth and free from sand holes, blow holes, distortion or any other defects.

Specifications:

Features:

1.Higher quality /higher tensile

2.Higher security /long life

3.Possibilities of new locking systems

About Our Company:

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard.

FAQ:

1. What is your products advantage?

A. All kinds of size as customer's requirements;

B. Small quantity trial order is welcome

C. Customized design is available and free, Such as Color, Logo, Panel, Load and Dimension etc.

D. Quality control and promptly delivery

E. Good after sales service

2. What is your payment?

T/T, L/C, D/P Western Union or as customer's requirements.

3. How about the shipment?

A. Small quantity you can choose by air

B. Less than one container you can choose LCL shipment by sea

C. One container or more than one container you can choose FCL shipment by sea.

Pictures:

Packaging & Shipping:

1.Packaging: Details Pallet with bubble film, Carton or with pallet,

2.Delivery Detail: 30-45 days.

- Q: How to calculate the price of casting parts?

- Cost of raw materials + electricity (fuel) costs + workers' wages + managers' wages + transport costs + raw materials burned + accessories costs + equipment maintenance depreciation costs + management fees + tax. The most convenient, the raw material market price plus 2000 yuan, plus you want profits on the line.

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- The three methods of metal processing have one thing in common. They are hot working, which are different in temperature and range of processing. Ductile cast iron is widely used because of its brittleness and poor impact. Heat treatment of cast iron usually adopts the annealing process, reduce the casting effect: 1 because of the internal stress caused by the thermal expansion and contraction, reduce the deformation after machining, decrease surface hardness, improve machining conditions;

- Q: What is the difference between forging parts and casting parts?

- No, it's called die castingDifference: the die casting parts are simple in structure and large in batch sizeCasting: the use of a wide range of structures without restrictions

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: What method of casting does not rust? I think the sample is like oil

- Close to the solder, and slowly dissolve is hot melt double-sided adhesive, otherwise it is oily double-sided adhesive.

- Q: How can the casting be quenched and tempered?

- Another is the result of pre heat treatment (quenching or annealing) after quenching and tempering treatment, suitable for ZG35SiMNMo, ZG35CrMo and so on. Please tell the casting process is your product and material and then set tempered.: shutup:

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- There are various casting stresses after casting, which can be divided into two kinds: thermal stress and shrinkage stress. In a long time placed in the atmosphere, called aging treatment.Aging treatment is an effective measure to eliminate casting stress. Aging is divided into natural aging, thermal aging and resonance aging.1, the so-called natural aging, the casting is placed in the open field for more than half a year, so that the internal stress relief.

- Q: Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

- Q: Is 316 casting better than 304 casting?

- It is comprehensive. There is no simple comparison of the material to determine the degree of difficulty in processing

- Q: Shandong foundry, casting small pieces of precision casting

- Small foundry in Shandong too much, like many of us in Qingdao, then Dongying Changshun investment casting is a home, they are also casting precision casting equipment, specifically what I recommend that local enterprises, far is not convenient,

Send your message to us

Ductile Iron Manhole Cover of High Quality Made in China

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 170 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches