Ductile Iron Manhole Cover B125 for Construction

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 3900 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Main Features:

1) Production information

manhole cover are manufactured for construction and public use .Manhole cover shall be smooth and free sand holes , blow holes , distortion or any other defects

2) Material

a) Ductile iron GGG500&400-12

B) Grey iron GG20

3) Designs

a) EN124 Class B125 C250 D400 ,with different size and grammage, or as per customers requirement

b) Major standards designs available

c) as per customers' drawing or samples

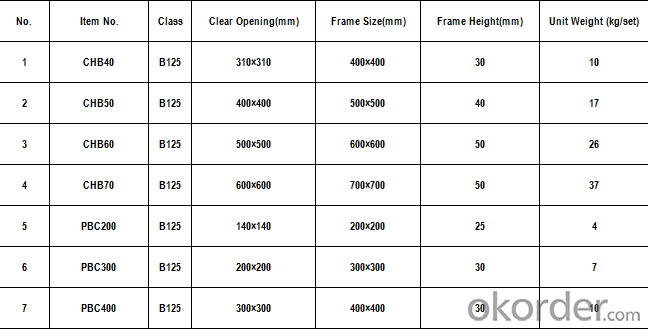

Specifications

Double triangle ductile iron manhole cover

1.Standard:ISO 9001 EN124 D400

2.Service:OEM

3.High quality

4.Made of ductile

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 30-45 days

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers. Our customer come from America, Morocco , saudi arabia, Iran , Algeria and so on

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

FAQ

1.Q: Are you factory ?

YES! We are a professional ductile iron &gery iron casting Factory in China.

2.Q: How long can you make your quotation:

Within 3 workdays after received your detailed product information

3.Q: Do you provide OEM Service?

Yes, we provide OEM Service.

4.Q: What 's your quotation element?

Drawing, material, weight and quantity.

- Q: What are the factors affecting the machining process of the casting material and structure?

- The impact on the machining is obvious, it should be the material and heat treatment of the castingCarbon steel parts should be treated by heat treatment (annealing) without special conditions. It can effectively prevent the uneven hardness and hard points. It is easy to turn.

- Q: What are the casting parts tested?

- The surface brightness, appearance, size, chemical composition, weight, material, surface defects, internal defects, seals need to be checked, leakage, etc.

- Q: Casting parts have poor surface finish. What sand is used to make them?

- V casting, EPC, precision casting of the surface is good.

- Q: The difference between cement sand castings, resin sand castings and vacuum casting parts

- The clay wet sand castings casting weight from a few kilograms until tens of kilograms, but the clay dry type of casting production can be weighed dozens of tons.For medium and large castings, cast iron, cast steel can be self hardening sand with resin can be water glass sand production, can obtain the precise size, smooth surface castings, but casting precision, surface roughness, density and microstructure, mechanical properties and material cost of sand casting production is often poor, so when the higher performance requirements of castings, should adopt other casting methods, such as casting (lost wax casting), die casting, low pressure casting.

- Q: Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- uch as: automobile transmission shaft adopts mechanical rolling machine with good performance, gray cast iron can play seismic effect effectively, with good thermal conductivity of radiator graphite in gray cast iron, the aircraft engine turbine blade by casting directional solidification casting and Dan Jingzhu.Do everything we can to make the best use of it, the advantages and disadvantages of rolling and casting, and you'll find it yourself, Baidu, depending on how you use it

- Q: What is the casting material?

- The casting material is usually made of gray cast iron, nodular cast iron and vermicular graphite cast iron

- Q: Why do casting parts have air holes?

- First, from the source, tools, raw material drying, in the process of melting into the reaction gas, another influence is pouring process, such as high temperature solidification gas dissolved too much after not excluded. The method can adjust the pouring temperature properly, control the source of gas (drying and controlling the inoculant, especially the content of magnesium), and add cooling iron to change the solidification mode. It depends on what kind of casting you are. You can't make it clear at once. And molding sand relationship is mainly water content and permeability, brush coating resin content.

- Q: Where is the precision casting factory?

- The National Precision Casting Factory is generally distributed in Shandong, Ji'nan, Jiangsu, Wuxi, Changzhou, Zhejiang, Guangdong, Panyu, Dongguan.The above are only the main distribution, many of Shandong are made supercharger, and Guangdong to jewelry industry based.

- Q: Which surface is coarser for cast iron or cast steel castings? Why?

- Roughness mainly depends on the surface roughness on the surface of the sand.

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

Send your message to us

Ductile Iron Manhole Cover B125 for Construction

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 3900 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches