Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm Mechnical Joint K Type

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ductile iron pipe fittings:

1.EN545/ISO2531 standard

2.rich zinc coat

3.epoxy/black bitumen paint

4.SGS approval

Detailed information:

1) standard: ISO25431, EN545, AWWA C153&C110

2) class: K12, K14

3) material: ductile iron

4). paint: epoxy paint or black bitumen paint with thickness above 70 micron.

5). zinc coat: outside sprayed with zinc in accordance with ISO8179, not less than 130g/m2

6). inside lined with cement mortar as per ISO4179.

7). pressure value: PN10,PN16,PN25.

8). Joint type: the normative joint are Push-on (Tyton-type) joint, we could also supply Mechanical (K-type) joint and flange type if requested.

9). rubber gasket: SBR, EPDM, or neoprene.

10). Minimum order: 1x20’GP.

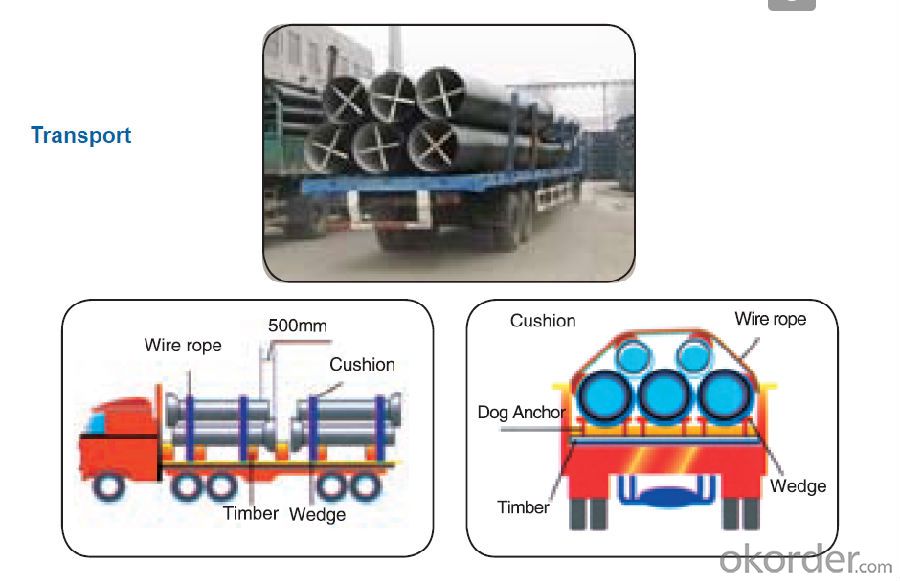

Transport:

- Q: What is the lifespan of ductile iron pipes?

- The lifespan of ductile iron pipes can vary depending on various factors such as the quality of the pipes, the environment they are installed in, and the level of maintenance they receive. However, on average, ductile iron pipes have a lifespan of approximately 80-100 years.

- Q: How does ductile iron pipe perform in extreme temperatures?

- Ductile iron pipe performs well in extreme temperatures due to its ability to expand and contract without cracking or breaking. It has a high thermal conductivity, allowing it to efficiently transfer heat without compromising its structural integrity. Additionally, its corrosion resistance properties make it suitable for both hot and cold environments, ensuring long-term performance even in extreme temperature conditions.

- Q: Are ductile iron pipes suitable for horizontal directional drilling (HDD) installations?

- Yes, ductile iron pipes are suitable for horizontal directional drilling (HDD) installations. Ductile iron pipes are known for their strength and durability, making them an excellent choice for HDD projects. HDD involves drilling a horizontal hole underground and pulling a pipe through it, which can be challenging due to the forces exerted on the pipe during installation. Ductile iron pipes can withstand these forces and maintain their structural integrity, ensuring a successful HDD installation. Additionally, ductile iron pipes have excellent corrosion resistance, making them suitable for various soil and environmental conditions encountered during HDD projects. Overall, ductile iron pipes offer the necessary characteristics to withstand the rigors of HDD installations and are a reliable choice for such applications.

- Q: Are ductile iron pipes suitable for installation in areas with high groundwater table?

- Indeed, areas with a high groundwater table are suitable for the installation of ductile iron pipes. These pipes are renowned for their exceptional strength and durability, rendering them perfect for underground installations. They possess the ability to endure the external pressure exerted by groundwater without any deformation or collapse. In addition, their outstanding resistance to corrosion shields them from the potentially harmful impact of groundwater. Consequently, ductile iron pipes can be confidently utilized in areas with a high groundwater table, ensuring the establishment of dependable and enduring water supply infrastructure.

- Q: Are ductile iron pipes suitable for use in acidic environments?

- Ductile iron pipes are generally not suitable for use in highly acidic environments. While ductile iron is known for its strength and durability, it does have limitations when it comes to acidic conditions. Acidic environments tend to corrode and degrade ductile iron pipes over time. In acidic conditions, the acid can react with the iron in the pipe, causing corrosion and ultimately leading to pipe failure. The rate of corrosion depends on various factors such as the concentration and type of acid, temperature, and the duration of exposure. Acidic environments with pH levels below 4 or 5 can significantly accelerate the corrosion process. To overcome this limitation, other materials like stainless steel or corrosion-resistant alloys such as PVC or HDPE (high-density polyethylene) pipes are often recommended for use in acidic environments. These materials have better resistance to corrosion and can withstand the harsh conditions associated with acidic environments. However, if ductile iron pipes are used in mildly acidic conditions or if measures are taken to protect them from corrosion, they may still be suitable. Applying protective coatings or linings to the pipes can help minimize the corrosive effects of acids. It is essential to consult with experts or engineers familiar with the specific conditions and requirements of the project to determine the most suitable material for use in acidic environments.

- Q: Can ductile iron pipes be used for geothermal energy systems?

- Certainly, geothermal energy systems can utilize ductile iron pipes. Ductile iron, being a robust and long-lasting substance, possesses the capacity to endure the frequently encountered elevated temperatures and pressures in geothermal energy systems. Its ability to resist corrosion and exhibit high tensile strength renders it a perfect selection for conveying geothermal fluids. Furthermore, the ease of joining ductile iron pipes permits flexibility and adaptability during the design and installation phases. All in all, ductile iron pipes prove to be a trustworthy and economically viable alternative for geothermal energy systems.

- Q: DN300 how long is it for water polo and iron pipes?

- Cast iron pipe (Cast Iron Pipe) with the cast iron casting pipe cast iron pipe for water supply and drainage gas pipeline pipe fittings including cast iron casting with fatigue strength by continuous cast iron pipe from the cast iron pipe from the cast iron pipe sand metal two according to material with grey cast iron pipe, ductile iron pipe at the interface with flexible sealing interface LAN interface, self anchored interface, interface of the rigid flexible cast iron pipes rubber ring;

- Q: What are the different sizes of ductile iron pipes available?

- Ductile iron pipes are available in a variety of sizes to cater to different applications and requirements. The sizes of ductile iron pipes typically range from 3 inches to 64 inches in diameter. These different sizes allow for flexibility and adaptability in various industries such as water supply, sewage systems, irrigation, and industrial piping. The smaller diameter ductile iron pipes, such as those in the range of 3 to 12 inches, are commonly used for residential and small-scale applications like household plumbing, fire hydrant systems, and small irrigation projects. These sizes are often found in urban areas and residential neighborhoods. For more extensive applications, larger diameter ductile iron pipes are utilized. They can range from 14 inches up to 64 inches in diameter. These larger pipes are predominantly used in municipal water supply systems, wastewater treatment plants, and industrial facilities where high-volume water flow is required. The availability of a wide range of sizes in ductile iron pipes ensures that they can accommodate various flow rates and pressure requirements. It allows engineers, contractors, and designers to select the appropriate size based on the specific needs of a particular project or application. It is essential to consult industry standards, local regulations, and engineering guidelines to determine the suitable size of ductile iron pipes for any specific project. This ensures that the pipes are capable of meeting the required performance standards and are suitable for the intended use.

- Q: Can ductile iron pipes be used in dam or reservoir projects?

- Yes, ductile iron pipes can be used in dam or reservoir projects. Ductile iron pipes are known for their durability, strength, and corrosion resistance, making them suitable for various applications, including water supply systems in dams and reservoirs. Additionally, their ability to withstand high pressure and adapt to ground movement makes them a reliable choice for such projects.

- Q: How can the three pipes of ductile iron leak?

- The raw material used in RE can be installed in the thread, can also be used on the same thread AB, re install is also available, but it is hard to remove.

Send your message to us

Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm Mechnical Joint K Type

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords