Dual Plate Wafer Check Valve/Oblea de Doble Placa Valvula de Retencion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Plywood case or buyer request |

| Delivery Detail: | Negotiation |

Specifications

1. Size: 2"-48"

2. Pressure: 150~2500LB

3. Material: WCB,WC6, WC9, C5, C12, CF8M, CF3, CF3M, ETC.

4. STD:API6D, ASME, JIS, BS

DUAL PLATE WAFER CHECK VALVE

1 | SIZE | (INCH) 1/2” 1” 2” 3” 4” 6” 8” 10” ....48” (MM) 15, 25, 50, 80, 100, 125, 150, 200, 250, ...1200 |

2 | PRESSURE | (CLASS) 150, 300, 600, 800, 900, 1500, 2500 (MPA) 1.0, 1.6, 2.5, 4.0, 6.4, 10, 13, 15, 25, 42 |

3 | BODY MATERIAL | A216WCB, , SS316, SS304, SS316L, CF8C, ETC CARBON STEEL, STAINLESS STEEL, DUPLEX STEEL, ALLOY, ETC |

4 | STANDARD | BS, ASME, API, DIN, JIS, GOST,EU, ETC |

5 | ||

6 | CONNECTION | RF FALNGE, RTJ FALNGE, BW, SW, NPT, THREADED, WAFER, LUG, ETC |

7 | MEDIUM | CORROSIVE ENVIRONMENT, OIL, GAS, WATER, ETC. |

8 | WARRANTY | 12 MONTH |

1. Design & Manufacture Std.: API594, ASME B16.34, API 6D, JISB2074-JISB2084, BS1868

2. Face to Face Std.:ASMEB16.10, API 6D, JISB2002, DIN3202, EN558

3.Test Standard: API598, API 6D JISB2003

Features:

1. Small and light, Tightly sealed. Less expensive than swing check valve.

2. Two torsion springs are used excerting on each of the pair valve plate,which close

the plate quickly and automaticlly.

3. The quick-close action prevent the meidum from flowing back and eliminates water hammer effectly.

4. Can be installed both horizontaly and vertical on pipeline.

5. Safe and reliable in operation, high interference-resistance.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

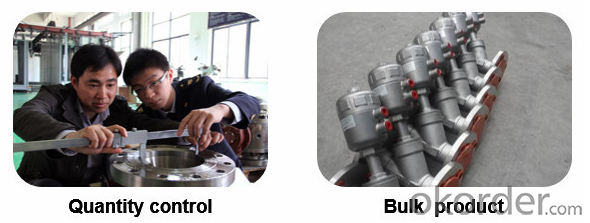

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: My house is public flue, a total of six floor I live five floors, with the side suction hood, hood in the windy outside started as soon as the check valve pops ring from occupancy, have what way?

- The hood check valve is in two halves of plastic. It is too light and the wind vibrates. You can add some things, as long as the soot blowing function is OK (try several times). Able to solve problems.

- Q: What kind of check valve is used in the sewage pump of sewage treatment plant?

- 2. installation of pump outlet check valve*Swing check valves are generally mounted on horizontal pipes: for bore DN~80mm check valves, they can also be mounted on vertical or upward sloping pipes.*Straight through lift check valves shall be installed on horizontal pipes; vertical lift check valves must be mounted on vertical pipes and medium upward flow.*As the check valve is easy to damage, therefore, should be installed near the pump outlet valve, in the upper part of the check valve with a cut-off valve (general use of ball valve or gate valve), easy to overhaul.*To facilitate the relief of the check valve before disassembly, the relief valve shall be installed between the check valve and the shut-off valve.

- Q: Why is the water ring vacuum pump equipped with check valves?

- The check valve is a one-way valve, the instantaneous vacuum of the stopping pump is higher than the pump cavity, and the gas enters the pump cavity from the exhaust port, and the water pressure is connected to the vacuum pipeline, and the function of the check valve is to prevent water from entering the pipeline

- Q: What are the differences between different check valves applications? For example, is the fire pump outlet swing check valve or a silent check valve? According to 35How to recognize single wall corrugated pipe and double wall corrugated pipe? Which is better?.What's the use of the silent check valve? And the bellow problem below, is there no answer?

- General pump station project, for the pump outlet check valve, the following principles should be observed;The outlet check valve shall be used when the diameter of the outlet pipe of the pump is smaller, that is, DN<50mm.The pipeline of the pump outlet pipe diameter DN is larger than 50mm, should be used in swing check valveSwing check valves can be installed horizontally or vertically.

- Q: Standard and specification for stop check valves

- Design and manufacture: GB12235 structure length: GB12221Pressure temperature range: GB9131, JB/T74, HG20604Connection flange: JB/T79, GB9113, HG20592Test and test: JB/T9092, GB13927

- Q: I would like to ask you the following questions: Recently, the newly purchased three Lin electric water heater, installed in the upper layer of the five bathrooms, a faucet, that is left to wring out hot water, to the right to wring out cold water, mixed type.1 when there is no safety valve, the hot and cold flow is normal, but the check valve is dripping.2 manufacturers said that the high level to safety relief valve, dripping water and this also concerned, it took more than 100 safety valve, on the cold water pipe, but since then, hot water flow and its small, cold water normal, the check valve is still dripping.3 excuse me, check valve, check valve, safety valve is not a thing? Is it just a different name?4 is the relief valve the same as the relief valve?Now it's really a tough one. How do you solve the problem of small drop of water and hot water flow? The manufacturer said the pressure, but I very cold water washed!Thanks for the answer!

- Well, it's useless to have all the valves removed. The original valve has all functions of the machine. Drip valve is normal, because your tank is a closed container, heated from cold water to hot water, the pressure inside its tank will increase a lot. Therefore, the pressure must be released, the valve is equivalent to burning rice cooker lid, rice porridge opened, the pot can top the overflow. The reason for the safety valve is the same. All the hoses should be removed.In a word: you are fooled, as long as a valve is enough. You don't need so much clutter. A safety valve is the one with a small mouth, and that mouth should be hose drain.The air heater is now used. The waste of electricity is out of date.

- Q: What does the H/F/P stand for in the check valve H41H/H41F/H41P?

- Respectively, the valve seat sealing surface is made of alloy / fluorine plastic / stainless steel.

- Q: Check valve h44h-25p what does that mean?

- H- stainless steel4- flange connection4- rotary single structure check valveH sealing material is Cr13 stainless steel25- pressure 2.50MPAP-18-8 stainless steelH44h-25p= stainless steel flange connection, swing type single check valve pressure 2.50MPA valve body, material 18-8 stainless steel

- Q: Does the check valve damage affect the flow rate?

- Ball check valve will not affect the flow, such as the clip type check valve once damaged, it will affect the flow.

- Q: What are the main types of check valves?

- Two, noun explanation:The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valve. Check valves belong to the automatic valve, mainly used for one-way flow of media channels, allowing only medium to flow in one direction, to prevent accidents.

Send your message to us

Dual Plate Wafer Check Valve/Oblea de Doble Placa Valvula de Retencion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords