CHECK VALVE WAFER TYPE DUAL PLATE DUCTILE IRON DN40- DN800

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Technical Date | Material Specification | ||

Nominal Diameter | DN40-DN1000 | Valve Body | Cast Iron or Ductile Iron |

Nominal Pressure | PN10/PN16 | Valve Disc | Cast Iron or Ductile Iron or Stainless Steel |

Operation Temperature | -40°C~225°C | ||

Flange Driling Standard | EN 1902-2 PN10/16 | Seal Material | EPDM OR NBR |

Suface Treatment | Painting | Valve Spring | Stainless Steel |

Application | Portable water, water distribution service & feed lines, sewage disposol, irrigation, fire protection pipe systerm, etc. | ||

| Quick Details | |||||

| Standard or Nonstandard: | Standard | Structure: | Check | Pressure: | Low Pressure |

| Power: | Pneumatic | Material: | Casting/stainless steel/bronze/ductile iron, Stainless steel,bronze,ductile iron | Temperature of Media: | Low Temperature |

| Media: | Water | Port Size: | Various | Place of Origin: | Zhejiang, China (Mainland) |

| Model Number: | Check Valve | Brand Name: | CMAX | Application: | General, Various Liquids |

| Certificate: | TS,ISO,API,CE | Life: | Long Life | Price: | Favorable and Reasonable |

| Quality: | Prime,High Quality | Supplier: | Factory Direct | Design: | Best Design |

| Feature: | Very Durable | Our Parterner: | PDVSA,BP,Sinopec Group,etc. |

Feature:

Tapa atornillada, columpio tipo disco

Aro roscado o soldado

ASTM A216 WCB, A217 WC6, A351CF8, A351CF8M,

A351 CF3, LOCALIDAD DE A351, A351 CN7M

Cumplimiento de los estándares

Diseñamos y fabricamos: ANSIB16.34, API6D, BS11868

Cara a cara (end to end): ANSIB16.10, API6D

Bridas de conexión: 2 ~ ~ 24 ~ 22 de ANSIB16.5 ~, 26 ~ ~ 36 ~ a MSS-SP-44 a API605 bajo petición

Tope extremo soldado: ANSIB16.25

Inspección y prueba: API598, API6D

Advantage:

Professional: We are professional manufacturer of valves.Ensure our valves is quality controlled and reliable.

Quality Control: We have been engaged in valve design for many year and can guarantee best quality

Experienced Sales Team: Our sales team is experienced, and they all know our product well.

About Price: we provide very reasonable and competitive price for you

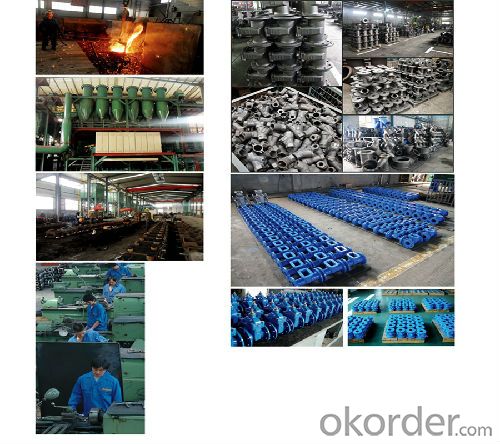

Our Capacity:

1)Date of foundation:2008

2)Total Revenue:Exceed $100 million

3)About QC: Excellence, quality first is our philosophy

4)Sales Market: Southeast Asia and other Overseas markets

5)Main Products: Gate Valves, Ball Valves, Check Valves, Butterfly Valves, Globe Valves, and Plug Valves

Materials | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: Should the kitchen check be mounted on the wall or on the hood?

- Buy their own check valve is generally in the wall of the hole, the hood of the smoke machine, usually with a check valve.

- Q: Circulating water check valve, I want to ask is not greater than DN600, you can use HBH747H hydraulic butterfly valve closed butterfly valve, less than DN600 of HD43X slow butterfly butterfly check valve, what does hydraulic check mean? Need hydraulic?

- Greater than DN600, you can use HBH747H hydraulic butterfly butterfly valve closed, less than DN600 with HD43X slow butterfly butterfly check valveThis is the usual selection, not necessary, there is no provision, but this choice is not wrong. There are, of course, other types of check valves.The hydraulic check valve is hydraulic, and the Baidu library contains instructions for the HB series and the HD series hydraulic check valves

- Q: The check valve for the printer doesn't have any air in it, but it doesn't come out. It still doesn't work

- Just change the CISS, change after dozens of photos. There is air in the pipe, the printing document is half a page, and then a check valve is installed. After it is finished, there is no air in the pipe, but it can not be played. The nozzle is not out of water any more. The ink in the ink box is full.When the check valve is installed, you can print the test paper color is correct, but the document is a piece of white paper. No more printing later. Say at least one cartridge problem. Where does the check valve open? No, there's a switchChasing the answerNot quite clear, you change the model, the general print cartridge does not leak, the ink box for the gas hole to open, hose without bubbles, you can print normally.

- Q: What type of check valve is the h61y-40 check valve?

- I. lift check valves: check valves that slide along the vertical centerline of the valve body. The lift check valves can only be installed on the horizontal pipe. The disc can be used in the high pressure small bore check valve. The valve body of the lift check valve is the same as the cut-off valve (which can be used with the stop valve), so it has a large coefficient of fluid resistance. The structure is similar to the cut-off valve, the valve body and the disc are the same as the cut-off valve. The lower part of the upper valve and the valve cover processing guide sleeve, the valve in the valve lift free guide simple simple light driven, when the medium downstream, the valve thrust open by the media, when the media stopped flow, the valve by the self vertical landing on the seat, preventing the media from the upstream effect. Straight through lift type check valve medium channel with import and export channel direction perpendicular to the valve seat; vertical lift check valve, the media import and export channel in the direction of the same direction with the valve seat, the flow resistance is smaller than the straight through.

- Q: What is the function of the check valve in the pipeline?

- Check valve, also known as one-way valve or check valve, refers to rely on the media itself flow and automatically open and close the valve flap, used to prevent the media back flow valve, also known as check valve, Dan Xiangfa, counter flow valve and back pressure valve.Effect:The function is to prevent backflow of medium in the pipeline. Pump water off the bottom valve check valve also belongs to class. The opening and closing parts depend on the flow of the medium and the power is turned on or off by itself. The valve that prevents the backflow of the medium is called a check valve. Check valves belong to the automatic valve, mainly used for one-way flow of media channels, allowing only medium to flow in one direction, to prevent accidents.Check valve installed in the pipeline system, the main role is to prevent media backflow, check valve is a kind of pressure on the media to open and close the automatic valve. The clip type check valve applies to nominal pressure PN1.0MPa~42.0MPa and Class150~25000; nominal diameter DN15~1200mm and NPS1/2~48; work temperature -196~540 degrees of various pipelines, used to prevent medium flow back. By choosing different materials, it can be applied to many mediums such as water, steam, oil, nitric acid, acetic acid, strong oxidizing medium and uric acid.

- Q: Check valve does not automatically check back, how to adjust?

- The non-return valve does not automatically check the cause:1, the valve at both ends of the road must be blocked, there is dry ventilated room. Such as long-term storage, should always check rust corrosion.2, the valve should be cleaned before installation and eliminate the defects during transportation.3, the installation must be carefully checked on the valve signs and nameplates are in line with the use of requirements.

- Q: What is the difference between the check valve h64h-250 and the h61y-250?

- According to JB/T308-2004 "valve type programming method"One is the swing check valve (4), and the sealing surface is Cr13 (H)One is the lift check valve (1), and the sealing surface is made of Y

- Q: Install check valve is not afraid of water, in case the back of the water pollution?

- The function of the check valve is to prevent water from flowing back. It is mainly installed at the outlet of the water pump to protect the water pump from reversing, so as to avoid the pump damage and mechanical accident.Usually between the water pump outlet pipe and the water tank inlet, must be equipped with check valve, to prevent water backflow!

- Q: How to install the water pipe check valve?

- The pipe type check valve is mostly in the form of clip type installation, which is suitable for the place where the installation distance is not enough!Understand more direct CALL I ~ user name is my Unicom number

- Q: How does the check valve work?

- Check valve refers to rely on the flow of the media itself and automatically open and close the valve flap, used to prevent the media back flow valve, also known as check valve, Dan Xiangfa, counter flow valve and back pressure valve. The check valve belongs to an automatic valve, whose main function is to prevent the backflow of medium, prevent the reverse of pump and drive motor, and release the container medium. The check valve can also be used to provide a supply to the auxiliary system where the pressure may rise above the system pressure. The check valve can be mainly divided into swing check valve (rotating by gravity center) and lift check valve (moving along the axis).The function of this type of valve is to allow the medium to flow in one direction and to prevent flow in the opposite direction. Usually the valve is automatically work, fluid pressure flow in one direction, the valve open; the opposite direction of fluid flow by gravity, fluid pressure and valve closing effect on the valve seat, thereby cutting off flow.Among them, the check valve belongs to this type of valve, which includes swing check valve and lift check valve. The swing check valve has a hinge mechanism and a gate like valve free against the inclined seat surface.

Send your message to us

CHECK VALVE WAFER TYPE DUAL PLATE DUCTILE IRON DN40- DN800

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords