Check Valve For Sell Liquid Best Quality Reliable Seal Good Performance 150-2500LB Oil Industry Chemistry Fertilizer Flux

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Check Valves

Check Valves are used in pipes under pressure between Class 150~2500LB, working temperatures﹣196~600℃. They are used in industries including oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

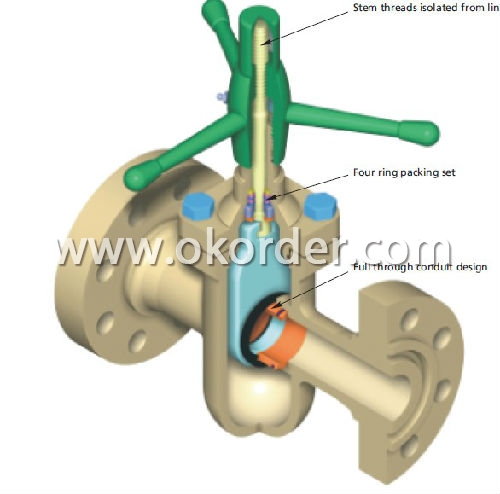

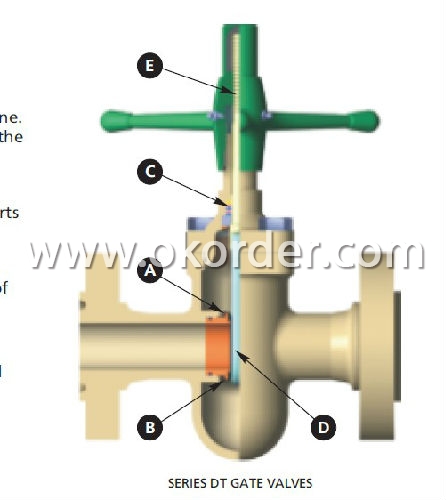

Design Feature of Check Valves

1. The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2. Either soft or hard seal can be selected for the product upon different working conditions. The sealing face is built up with Co-based carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3. Small opening pressure, the disc can be opened fully with a very small pressure differential.

4. Inside-set bolt-bearing structure reduces leakage and reliable use.

5. Class≥1500LB, the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along with the pressure rise so as to ensure the sealing performance.

6. Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirement

Technical Data of Check Valves

| Size | DN40-DN600 |

| Face to Face | DIN 3202 F6 |

| Flange Drilling | EN 1092-2 PN16 |

| Inspection and Test | ISO 5208 |

﹡For all available general design, face to face standard and flange drilling,please kindly contact CNBM directly.

Materials of Parts

| Parts | Description | Material |

| 1 | Body | GG25 |

| 2 | Seat Ring | Brass |

| 3 | Disc Ring | Brass/EPDM |

| 4 | Disc | GG25 |

| 5 | Hanger | GGG50 |

| 6 | Hanger Pin | Stainless Steel |

| 8 | Cover Gasket | Graphite with Soft steel |

| 9 | Cover | GG25 |

﹡For other material request,please kindly contact CNBM directly.

Dimensions of Check Valves

| Size(DN) | L | D | D1 | D2 | b | n-d | H | W.T(kg) |

| 40 | 180 | 150 | 110 | 84 | 18 | 4-19 | 110 | 9 |

| 50 | 200 | 165 | 125 | 99 | 20 | 4-19 | 130 | 13.4 |

| 65 | 240 | 185 | 145 | 118 | 20 | 4-19 | 140 | 17.7 |

| 80 | 260 | 200 | 160 | 132 | 22 | 8-19 | 150 | 20.8 |

| 100 | 300 | 220 | 180 | 156 | 24 | 8-19 | 160 | 29.3 |

| 125 | 350 | 250 | 210 | 184 | 26 | 8-19 | 190 | 47 |

| 150 | 400 | 285 | 240 | 211 | 26 | 8-23 | 210 | 67 |

| 200 | 500 | 340 | 295 | 266 | 30 | 12-23 | 250 | 118.7 |

| 250 | 600 | 405 | 355 | 319 | 32 | 12-28 | 310 | 171.9 |

| 300 | 700 | 460 | 410 | 370 | 32 | 12-28 | 340 | 232.5 |

| 350 | 800 | 520 | 470 | 429 | 36 | 16-28 | 450 | 330 |

| 400 | 900 | 580 | 525 | 480 | 38 | 16-31 | 520 | 460 |

| 450 | 100 | 640 | 585 | 548 | 40 | 20-31 | 550 | 580 |

| 500 | 1100 | 715 | 650 | 609 | 42 | 20-34 | 590 | 700 |

| 600 | 1300 | 840 | 770 | 720 | 48 | 20-37 | 680 | 780 |

- Q: What happens when the check valve is broken?

- Check valve is broken, there will be back water, down pressure, serious will produce pump reversal, burning motor

- Q: What does the check valve "h61h-25 H" mean?

- From the model analysis, for the cast steel welding lift check valve, it depends on your valve is not it

- Q: 40 how large check valves are installed in the water pipes?

- Crown valve press40 of the pipe outer diameter of 48 DN40 check valve on it

- Q: Does one-way check valve affect water flow?

- The water inlet of the household water heater is equipped with a triangle valve, which will not affect the flow of water, and be convenient for maintenance and inspection

- Q: What's the W in the check valve H44W?

- First, the meaning of "W" in check valve H44W:The H44W in the check valve W represents the seat of the check valve, and the sealing surface or lining material is the body sealTwo, check valve H44W model significanceLetter H: stands for check valveFirst number 4: the driving mode is the positive gearSecond numbers 4: the connection form is the flange

- Q: Can the check valves fit two in one tube? One up, the other down

- A water pipe is used for launching, and the two check valves that you install are reverse, and the water is blocked by one of the check valves on either side

- Q: Tap water tank with vertical and horizontal check valve.

- Ball valves usually have very narrow seats, and may remove solids and make seating more efficient.The problem of vibration may be limited to small valves. When the valve is large, the inertia of the moving parts increases. The increased inertia may effectively damp the vibration and cause delayed closing, after the backflow has started. The damping of the seat becomes very important.All valves must check the flow path area and calculate the flow velocity for the design operating conditions. The area of the disc and piston is as important as the area of the main orifice. The smaller runner areas are corrosion prone and may cause cavitation wear.For specific functions, the valve body of the check may include auxiliary connections such as vents and drains. Hot applied valves may sometimes have a bypass valve to allow the system to warm up at low flow.

- Q: How to prevent the backflow valve of medium

- Among them, the check valve belongs to this type of valve, which includes swing check valve and lift check valve. The swing check valve has a hinge mechanism and a gate like valve free against the inclined seat surface. In order to ensure that the valve can reach the appropriate position of the seat surface at any time, the disc is designed in the hinge mechanism so that the disc has enough swing space to make the disc real and comprehensive contact with the valve seat. The disc can be made of either metal or leather, rubber, or synthetic coverage, depending on performance requirements. The swing check valve is almost completely open and the fluid pressure is almost unimpeded, so the pressure drop through the valve is relatively small. The check valve of the lift check valve is located on the valve seat sealing surface of the valve body. In addition to this valve disc is free to lift, like the rest of the cut-off valve, the fluid pressure valve from the valve seat sealing surface lift, medium return led down to the valve seat, and cut off the flow. Depending on the service conditions, the disc can be of all metal construction or in the form of a rubber pad or rubber ring on the valve frame. The same as the cut-off valve, lift check valve fluid through the channel is narrow, so the check valve by lifting the pressure drop than the swing check valve a little bigger, and swing check valve flow restrictions very little.

- Q: Which side of the gate is the fire check valve in the pump room?

- The check valve is installed between the shock absorbing flexible joint and the water outlet control valve at one side of the water outlet pipe of the water pump

- Q: I have to use a check valve to prevent return water due to pipe installation problems due to regular water supply. But the recent discovery of a running water phenomenon, just on a full tank of water slowly from the pipeline flow away, but not all go, a flow did not flow, time is not the same, but sometimes sometimes does not flow, this is going on, ask professional personage answer

- You should be horizontal check valve, with pressure difference, water pressure is not lost; or a check valve inside where the card, must be a certain pressure to baffle back.The problem can't be solved: if you change the pipe, you'll have a vertical check valve

1. Manufacturer Overview

| Location | Beijing,China |

| Year Established | 1986 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, Asia, America, Europe, Middle East, West Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Beijing |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 498 People |

| Language Spoken: | English,Chinese |

| b) Factory Information | |

| Factory Size: | 42000 square meters |

| No. of Production Lines | Above 20 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Check Valve For Sell Liquid Best Quality Reliable Seal Good Performance 150-2500LB Oil Industry Chemistry Fertilizer Flux

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 sets pc

- Supply Capability:

- To Order pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords