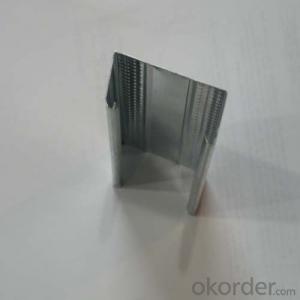

Drywall Wall Angle for Interior Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Drywall Wall Angle for Interior Decoration use

Detail description

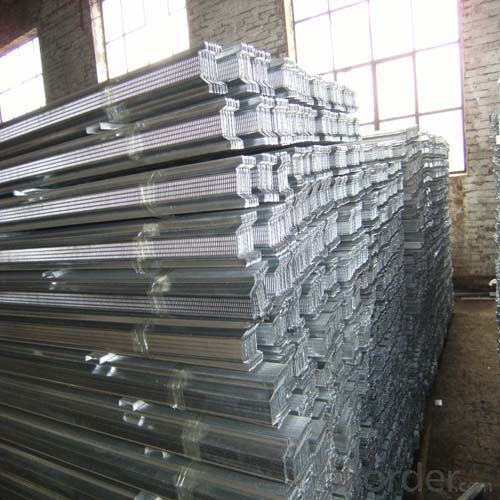

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized stee strip zinc coating is 80-180g/m2.

3.Warm sales in Middle East , Africa , Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services

4. The specification can follow up customer requirments.

5. Advanced equipment can make sure exactly size, high quality products.

Drywall 35*22*12*68, thickness 0.45mm - 1.0mm,length 2.8mm,2.9mm,3mm

Drywall channel system some sizes as follows:

a) Stud:

70x35x3000x0.45/0.5/0.6mm

50x35x3000x0.45/0.5/0.6mm

b) Track:

72x25x3000x0.45/0.5/0.6mm

50x25x3000x0.45/0.5/0.6mm

Furring ceiling system some sizes as follows:

a) Furring channel: 35x22x12x300x0.45/0.5/0.6mm

b) Main channel: 38x10(12)x3000x0.45/0.5/0.6mm

c) G.I. Wall angle:

25x25x3000x0.45/0.5/0.6mm

23x23x3000x0.45/0.5/0.6mm

22x22x3000x0.45/0.5/0.6mm

20x20x3000x0.45/0.5/0.6mm

Advantages of Galvanized track

1.Our products’ raw material is highquality hot dipped zinc galvanized steel strip, absolute fireproof and heatinsulation, waterproof and antirust, anticorrosive , high durability

2. Hot dipped zinc galvanized steelstrip zinc coating is 80-180g/m2.

3.Selling well in Middle East , Africa ,Australia, Malaysia ,and America , where the products haveenjoyed an excellent reputation with high quality and services

4. We canprofessionally manufacture the special specification products for customers.

5.Advanced equipment and technology can make sure the products exactly size, high quality

Application

1,Supermarket, marketplace

2,Underground, air port, bus station

3,Building lobby,metro station

4,Hotel, restaurant,railway station

5,School, office, meeting room ,hospital

6.commercial building

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures:

- Q: I was not a tool in the category, or else I got myself!

- I think you do so sound insulation is not the middle of the need to add sound insulation materials. There are many kinds, such as noise insulation cotton class. The more types of composite materials, the more layers, the sound and sound effects the best. It is best to have sound and sound effects have to reduce the sound of the rebound.

- Q: The designer said the solid wood flooring keel hit the prefabricated board after the lack of effort in the future may not be strong?

- 1: you have the conditions or bricklayers, practice: build the wall of the place, you can add a reverse beam (plus a beam on the floor) and then wall, reinforced concrete beam; another direct to do the word steel or channel to do Beam, pay attention to the two heads to be on the point of support. Build the wall again. ? 2: do light steel keel gypsum board wall accidentally wear a hole. Is a short time to be. Not moisture, is easy. 3: the floor can be made of wood, the material with a little bigger. Encrypt a little bit. The problem is not big, other solid floor to do on the ground fixed point has changed the day.

- Q: Now what is the room wall material is fashionable? Environmentally friendly

- Now home improvement wall materials are generally light steel keel + sound insulation cotton and light brick wall two, two have their own advantages and disadvantages, brick wall thickness, and space, sound insulation and no sound insulation board is good ; Light steel keel plus gypsum board cut off the knock will be pound, but if it is to consider the bedroom wall after the TV, then the best use of light steel keel + noise cotton, because the hanging must be hanging on the keel, or hanging The In addition, can also be resistant to sound insulation board, thinner board sound insulation effect is better, but the price is relatively expensive. General high noise requirements such as the hotel is used in such a soundproof board.

- Q: Light steel keel wall waterproof

- The grass on the surface of the gray skin with a knife to remove, with a broom to dust, sand and other debris clean, especially the root, floor drain and drain and other parts to be carefully cleaned. If there is oil, apply wire brush and sandpaper brush off. The base surface must be flat, the depression should be filled with cement putty.

- Q: Decoration decoration works Light steel keel wall, layer 4 meters high thickness What are the requirements? There is no specific specification?

- Save material, reduce human input The use of the fixed screw of the keel and the angle of the fixed support column are used as the reinforcement of the ridge of the ridge, which changes the traditional construction method of embedding steel and fixed expansion bolts in the ridge, saving the material and reducing the manpower Of the input.

- Q: How to install light steel keel gypsum board wall

- Gypsum board installation, should be used in vertical arrangement, keel gypsum board should be wrong on both sides. Gypsum board and keel can be fixed with self-tapping screws. 12mm thick gypsum board with 25mm long self-tapping screws; two 12mm thick gypsum board with 35mm long self-tapping screws. Self-tapping screws from the edge of the gypsum board should be at least 10 mm in the board edge of the paper, at least 15 mm in the cut edge of the board. The screw cap should be buried inside the board, but no damage to the paper. Self-tapping screws from the center of the board should be 250mm, in the middle of the board should be 300mm.

- Q: Light steel keel gypsum board partition should pay attention to what quality problems

- For the wall (or the top wall of the building), the distance between the vertical keel shall not be greater than 400mm, the distance between the transverse keel shall not be more than 600mm, and the fire gypsum board shall be used. Fixed, the upper edge of the gypsum board fixed on the top with the keel, the board from the floor should be greater than 20mm, and fire sealant with solid.

- Q: Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- The practice is to first play on the ground and shed on the corner keel must be vertical after the installation of the main keel times the keel installed in the plaster board plaster brush latex paint difference is stronger than the keel cost is higher than the wood keel

- Q: What is the pros and cons of a brick or a gypsum board?

- Part of course is the use of light steel keel gypsum board is now very popular I am doing this business

- Q: Light steel keel partitions and finished partitions

- Finished partition, generally used in business office buildings, factory production, on-site installation, at one go without any construction in the field to do the operation, removable, removable heavy equipment.

Send your message to us

Drywall Wall Angle for Interior Decoration

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords