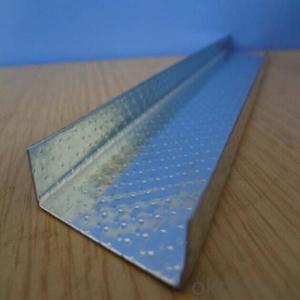

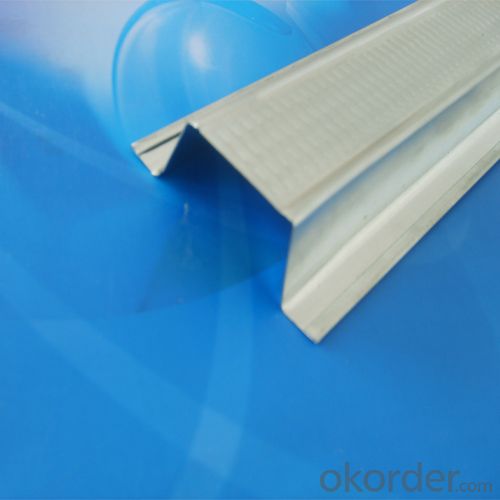

Drywall Vertical Keel In Steel Framing System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification(Width*Height*Gauge): (Customization Acceptable)

Product Code | Width(mm) | Length(mm) | Gauge(mm) | Height(mm) |

QC50 | 48 | customization | 0.4/0.5/0.6/0.7 | 50/45/40/35/30 |

QC60 | 58 | customization | 0.4/0.5/0.60.7 | 50/45/40/35/30 |

QC75 | 74 | customization | 0.5/0.6/0.7/0.8 | 50/45/40/35/30 |

QC90 | 89 | customization | 0.5/0.6/0.7/0.8 | 50/45/40/35/30 |

QC100 | 98 | customization | 0.5/0.6/0.7/0.8 | 50/45/40/35/30 |

Other specifications | Orders can be customized | |||

2. Specification

commodity | size (mm) | thickness (mm) | length (mm) | pack |

Australia system | ||||

Primary cross rail | 25*21 | 0.55, 0.75,0.85,1.0 | 3600, 4800 | 10 |

Furring channel | 28*38 | 0.55, 0.75,0.85,1.0 | 3000,3600,4800 | 25 |

Wall track | 26*16*26 | 0.45,0.55,0.75 | 3000 | 20 |

Angle | 30*30 | 0.55, 0.75 | 3000 | 50 |

Stud | 51*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 |

64*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

76*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

92*35.5 | 0.55, 0.75 | 2400,3600,4800 | 10 | |

Track | 51*32/50 | 0.55, 0.75 | 3000 | 10 |

64*32/50 | 0.55, 0.75 | 3000 | 10 | |

76*32/50 | 0.55, 0.75 | 3000 | 10 | |

92*32/50 | 0.55, 0.75 | 3000 | 10 | |

Middle East system | ||||

Main channel | 38*12 | 0.45,0.50,0.60,0.80,1.0 | 2400,2950,3600 | 20 |

Furring channel | 68*35*12 | 0.40,0.45,0.50,0.60 | 2400,2950,3600 | 25 |

Edge channel | 25*25 | 0.35,0.40,0.45,0.50 | 3000 | 50 |

Stud | 50*34.5 | 0.40,0.45,0.50 | 3000,3600,4800 | 10 |

70*34.5 | 0.45,0.50,0.60 | 3000,3600,4800 | 10 | |

75*34.5 | 0.45,0.50,0.60,0.70 | 3000,3600,4800 | 10 | |

100*35 | 0.50,0.60,0.70,0.80,1.0 | 3000,3600,4800 | 10 | |

Track | 52*25 | 0.40,0.45,0.50 | 3000,3600,4800 | 10 |

72*25 | 0.45,0.50,0.60 | 3000,3600,4800 | 10 | |

76*25 | 0.45,0.50,0.60,0.70 | 3000,3600,4800 | 10 | |

100*25 | 0.50,0.60,0.70,0.80,1.0 | 3000,3600,4800 | 10 | |

East Europe system | ||||

CD | 60*27 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 12 |

UD | 28*27 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 20 |

T-type keel | 20*6 | 0.35,0.40,0.45 | 2400,3000,3600 | 50 |

24*10 | 0.35,0.40,0.45 | 2400,3000,3600 | 50 | |

Stud (CW) | 50*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 |

70*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

75*50 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

100*50 | 0.40,0.45,0.50,0.60,0.80,1.0 | 2800,3000,3600 | 10 | |

Track (UW) | 52*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 |

72*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

75*40 | 0.40,0.45,0.50,0.60,0.80 | 2800,3000,3600 | 10 | |

100*40 | 0.40,0.45,0.50,0.60,0.80,1.0 | 2800,3000,3600 | 10 | |

Drywall section metal profile

1. Usage: gypsum board drywall

2.Easy to install

3.High strength

4.Size exact, easy cut

Product Overviews

Advantages and features:

1. Galvanized Steel Profiles raw material is high quality hot dipped zinc galvanized steel strip, absolute damp proof , heat insulation and high durability , high rust resistance.

2. Hot dipped zinc galvanized steel strip zinc coating is 60-180g/m2.

3.Warm sales in Middle East , Africa , Australia, Malaysia ,and America , which have enjoyed an excellent reputation with high quality and services.

4. The specification can follow up customer requirements.

5. Advanced equipment can make sure exactly size, high quality products.

6.High quality cold rolled continuous hot galvanized plate as raw materials which makes sure it is anti-corrupt and anti-rusty

7.drywall steel profile adopts excellent manufacture equipment,advanced production process, scientific and detecting method.

8. Steel profile has beautiful surface, medium hardness! Good quality *competitive price large quantity *honesty *good after-service

Certificates ISO 9001:2000 Quality management system

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Light steel keel partition wall fire retardant coating shabu several surface

- Brush when, in accordance with the requirements, at least need to brush twice. Although the Tai Po people in practice only brush it again, but suggest that you still brush twice for safety.

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- But in a dry place, with a 20 years no problem, light steel keel life and its wall thickness, sealing plate varieties and thickness are closely related. Do not worry about the damp environment, it is recommended to use light steel keel partition, after all, it has light, space-saving, construction convenience, the cost is relatively low advantage.

- Q: How to remove the gypsum board cut off

- Before the demolition, look at the original decoration construction drawings, or consult the owners, understand the distribution of water and electricity, wall decoration materials, cut off size and so on. If the partition inside there are hydropower, first the total valve or related valve closed to remove the partition. If the decoration materials are tiles and the like, pay attention to the ground to do protection, so as not to drop the ground tiles. To see whether the wall is anti-magnetic or wall whether there is sound insulation material, if any, must be done before the demolition of the relevant anti-magnetic or noise protection measures to avoid demolition later less than remedial loss. If the larger size of the partition is necessary, the first partition wall to do the guardrail, or playing keel, as a fixed wall, and then split.

- Q: Light steel keel + gypsum board wall and other wall joints how to strengthen?

- Are generally used to deal with the patch to prevent the brush at the brushing of latex paint, keel and wall connection more than a few nail fixed

- Q: Light steel keel wall Why do not cross brace welding with welding

- Horizontal keel is a secondary support role, the panel position is not time to adjust the location, in addition to the function of contraction expansion margin, so not allowed to link the link for the rigid.

- Q: In a layer of 6 meters high in the big room, do 2.8 meters high light steel keel partition. Big room to do mineral wool board ceiling, how to connect the two?

- If the middle of the empty iron angle, it is estimated that the master will be in the corner iron welding rods down to install! Some of the master will use wire hanging, but many people do not use the iron wire rod. Then install baking paint or paint keel, Put the mineral wool board up just fine!

- Q: What kind of new material is now called a "light partition" in the house? Is it safe?

- Light steel keel inorganic composite board wall of the impact resistance and load-bearing performance is also very good, ordinary furniture hit the wall, no damage, even if the impact of an adult's running jump, no damage, no cracks in the wall, no deformation , The intensity is twice the international standard. Wall load-bearing capacity is unequivocal, the maximum load of 75kg, to meet the needs of most of the majority of the normal use of the family. To the wall hanging paintings, shelves and other daily items, with screws fixed on the wall hanging on OK; hanging TV, air conditioning, hanging cabinets and other heavy objects, just use the expansion bolt to do reinforcement treatment can be used at ease.

- Q: Light steel keel partition wall how to paint

- Light steel keel structure, to find the location of the keel, use a long self-tapping screws, forced into the screw. So that it can be stable.

- Q: How to do woodworking partition wall, with door

- Wood keel partition wall is made of red, white pine do skeleton, gypsum board or wood fiber board, plywood for the panel of the wall, its processing speed, low labor intensity, light weight, sound insulation effect is good, widely used.

- Q: 100 light steel keel 9.5mm thick gypsum board double double-sided partition three times, three times latex paint.

- The following is the decomposition of the material (no loss), vertical wall keel spacing is generally @ 400, vertical keel is 2.5m / m2; along the top edge (heaven and earth) keel is 2/3 = 0.67m / m2; Piercing board is 4m2 / m2 partition wall area; large white putty is about 2.5kg / m2 partition wall area, latex paint is 0.5kg / m2 partition wall area. Brush twice to consider; the rest Is the card pieces, nails, bandages, white latex, high-strength nails and oblique support cable-stayed material (wood can be) and other auxiliary materials Usually the wall should also have rock wool, 50 thick or 75 thick

Send your message to us

Drywall Vertical Keel In Steel Framing System

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords