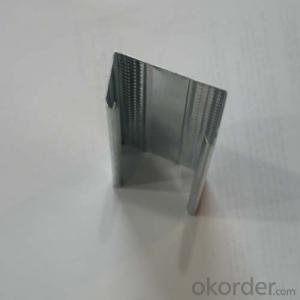

Drywall Partition Galvanized Steel building keel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.MOQ:20 Ton

2.Material:Q195,Q235

3.Size:0.7--3mm

4.Used for:upvc door and window

Name | steel lining,steel angles,steel framing ,metal frames, |

Technique | Cool rolled |

Thickness | 0.7~~3.0mm |

Dimensions | 12mm*150mm*1.5mm(Size range Or Other Size According To The Contract) |

Length | 5.8m usually Or Other Size According To The Contract. |

Steel Material | Q195-Q235 |

Type | C,L,U,or Profiled steel angle. |

Application | The doors and windows strengthen steel. |

Surface | Bared Or Painted, Galvanized Or Clients’ Option. |

Country of Origin | China(mainland) |

Package | Containers Or With Other Clients' Requirements. |

Port | Tianjin |

Delivery Time | Within 15 days(30% in advance) |

Introduction:

purlin and wall beam of steel structure building

The C-shaped purlins have excellent anti-bending property and are easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

Advantage:

(1). Design according to customers’ requirements

(2). Manufacture under complete quality control system---ISO9001:2008

(3). Installation with instruction of experienced engineers

(4). Easy to assemble and dismantle

(5). Eco-friendly material: can be used for several times and can be recycled

(6). Shorter construction period, longer using time

(7). High strength and stiffness, high weight bearing.

Product Show

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: In Shanghai 75 partition wall light steel keel 0.6 what price now

- Low-grade 3.5-4.5 yuan / m range. Light steel keel, flower head a lot. Side high, the actual thickness, galvanized surface, strip material are very affected price.

- Q: Light steel keel cut off the keel and the ground with what fixed?

- Expansion bolt or pad on a layer of blockboard (brush fire anti-corrosion coating) with 50 steel row nail directly on the ground

- Q: The room to remove the partition, can not retain the original light steel keel gypsum board ceiling?

- But this will be more expensive construction costs

- Q: Light steel keel gypsum board wall height is how to determine

- D = <l 240 Parameter Description: d: Maximum deformation of the component under uniform load, unit mmq: Uniform load, unit Pa, test In the composition of the material, the cross-sectional nature of the wall stiffness coefficient: EI value of the test to determine the length of the wall The use of 15mm plate instead of 12.5mm plate, the wall stiffness EI can be increased by 33% 2. The keel spacing from 600mm to 400mm, wall EI value increased by 50% 3. The keel spacing reduced from 400mm to 300mm, the wall EI value increased by 50% 4. keel on the wall than the non-buckle wall, EI value increased by 60% 5. Use type I keel than the use of C-keel, EI value increased by at least 100%. The effect of thickness on the EI value is very small relative to several other factors, EI is called bending stiffness, 75 keel spacing is 400, double-sided single layer 12mm gypsum board wall EI = 4.6 × 1010 according to the actual test EI value of the structural partition system: (unit: N.mm2, 1010)

- Q: What is the decoration of the wall? Lightweight bricks Or light steel keel frame?

- Decorate the wood keel can be, and then use the integrated wall covered up on it. The other keels are too much trouble and time.

- Q: How to remove the gypsum board cut off

- Partition may be a metal structure, can not be sparks in the environment, can not use cutting machine, can not use metal hit metal. Can not use the fire.

- Q: Waterproof gypsum board for toilet partition and paste tile installation steps?

- The exterior wall of the bathroom is made of ordinary type gypsum board (size 1.2M * 3.0M). Can be fixed with pneumatic nails, can also be used 4 * 20 anti-rust self-tapping screws.

- Q: Use light steel keel to do the shelf, install the glass partition wall, this process is feasible? How about construction?

- Must want to do it. Recommended use of lacquered glass (keel must use heavy-duty installation of reliable), or white glass selection of aluminum keel. More reliable.

- Q: Can the gypsum board be painted on the wall

- You can play tuxedo on the keel on the line

- Q: With light steel keel gypsum board do partition wall price how to count?

- Double-sided labor costs more than 20 yuan per square meter, the material to see the grade of gypsum board and the thickness of the keel. Generally not more than 20 yuan per level. Plus freight and handling costs, loss. Offer 60 yuan per flat can be.

Send your message to us

Drywall Partition Galvanized Steel building keel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords