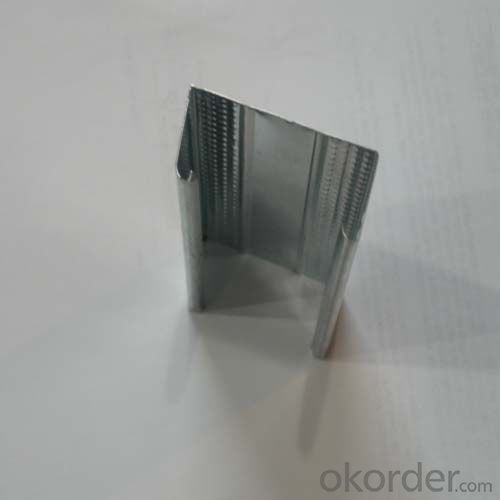

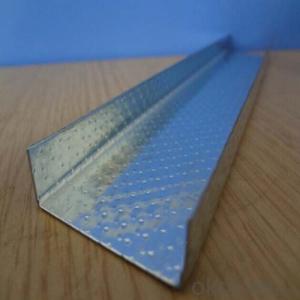

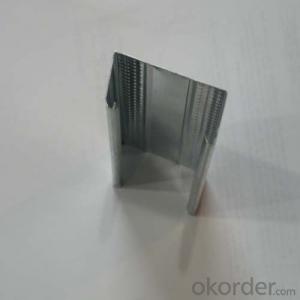

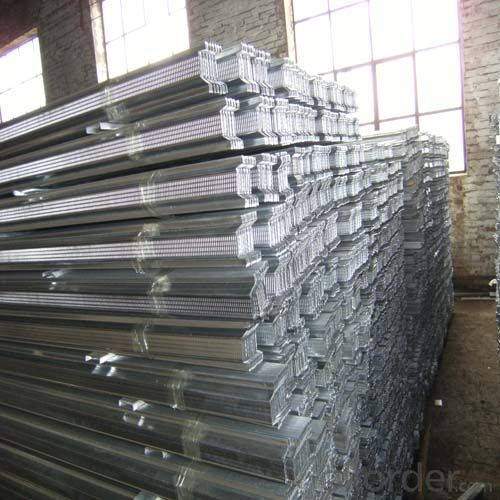

Drywall Metal Studs and Tracks Professional Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 550000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product characteristic

1) High quality of raw material with hot dipped Galvanized steel coil

2) Easy to operate and solid after installation

3) Durable for at least 10 years life-span

4)Moisture proof , Rust resistance

5)Many difference size. Export to different market

Specification for middle east:

Main Channel 38*12

Furring Channel 68*35*22

Wall angle 25*25

C stud 50*35

C Stud 70*35

C stud 75*35

U track 52*25

U track 72*25

U track 75*25

Specification to Australia:

top cross rail 25*21*0.75

25*21*0.75

Furring Channel 28*38*0.55

16*38*0.55

Furring Channel track 28*20*30*0.55

16*20*30*0.55

Stud 64*33.5*35.5

76*33.5*35.5*0.55

Stud 92*33.5*35.5*0.55

150*33.5*35.5*0.55

Track 51*32*32, 64*32*32*0.55

76*32*32*0.55

Track 92*32*32*0.55

Specification to Europe, Russia, Ukraine, Georgia. ect

C Stud 60*27

U track 28*27

C stud 50*50

C stud 75*50

C stud 100*50

U track 50*40

U track 75*40

U track 100*40

Advantages and Features:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6. We can supply you the products based on your specific requirements

Other Products Available:

38 light steel main channel,50 light steel main channel,60 light steel main channel,75 stud,100 stud,.50 track,75 track,100 track.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures

- Q: How to install damping sound insulation felt

- 1, along the wall laying sound insulation felt, seam at the pressure seam processing; ???? 2, the installation of vibration keel, wedge around 600mm; keel gap filled with cotton; ???? 3, vibration-proof keel installed on the noise board (two-layer board clip insulation felt, sheet and sound insulation stitch treatment)

- Q: 75 light steel keel wall to do 6m high, need reinforcement? How to strengthen?

- Must do 75 keel, it is recommended to add angle iron or square tube reinforcement, do not forget to do heart keel

- Q: Light steel keel wall circuit how to wear pipe

- Install the crossed keel (lower threshold). Fixed with a nail, or first drilling, and with the expansion bolts connected to fixed. Installation should be installed according to the center line and edge, both ends of the top to the structural wall (column) surface, the final fixed point from the structure of the facade should not be greater than 100mm; nail or expansion bolt spacing should not be greater than 800mm. Installation should ensure that the keel level and straightness.

- Q: Lightweight wallboard light steel keel how to construction

- Damp room and steel plate plaster wall, light partition board keel spacing should not be greater than hundreds of millimeters, the installation of supporting keel, the support card should be installed in the direction of the vertical keel opening, partition wall card should be four hundred To six hundred millimeters, from the keel at both ends of the distance should be twenty to twenty five millimeters, should be fixed according to the location of the ball along the edge, along the keel and border keel, keel line should be coincident with the line.

- Q: Shanghai light steel keel ceiling wall how much labor costs?

- If you buy materials to make people do not directly specify the material model specifications, directly called light steel keel, specifically do fast and good.

- Q: Light steel keel wall waterproof

- The grass on the surface of the gray skin with a knife to remove, with a broom to dust, sand and other debris clean, especially the root, floor drain and drain and other parts to be carefully cleaned. If there is oil, apply wire brush and sandpaper brush off. The base surface must be flat, the depression should be filled with cement putty.

- Q: Can my light steel keel ceiling withstand the weight?

- To be honest, the thickness of light steel is not visible, and even your different specifications are difficult to identify together. If the figure shown on the release of these things did not occur under the deformation of light steel, it should be no problem

- Q: House decoration, the designer said the wall with light steel keel good, but the construction told me that this low efficiency can only be maintained for 4,5 years so I do not know in the end listen to who

- Mainly to see the use of the environment, if used in a humid environment, the life must be short, so the bathroom wall is best not to use light steel keel search.

- Q: Light steel keel gypsum board partition design should pay attention to what the problem

- In order to be able to make decoration more perfect, it is recommended that you choose the decoration manufacturers, to be careful, we must choose the same brand of all products. The

- Q: Light steel keel installed security door how loaded really

- It is recommended to install two square steel pipes vertically and fixed on the concrete floor and floor. The security door is mounted on the square steel pipe

Send your message to us

Drywall Metal Studs and Tracks Professional Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 550000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords