Double Stage Chemical Industry Vacuum Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

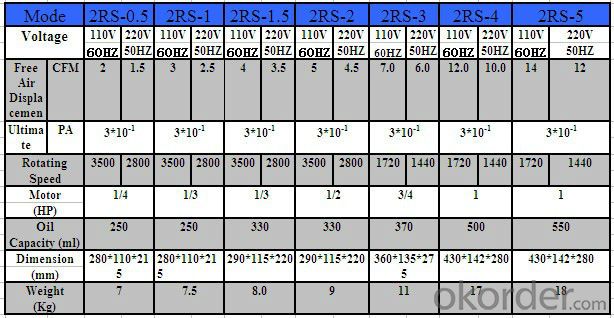

1,Material:Aluminum Alloy casing2,Pumping speed:6/7Cfm

3,Warranty:1 year.

4,Minimum order:1 set.

◊ Application

RS Series vacuum pump is compact, light and attractive in design. It uses the big starting torque and is specially designed for low temperature environment. It is guaranteed start normally in winter’s low temperature. It is applicable to vacuum packaging, vacuum freez

This kind of pump is widely used in food packaging, scientific research, medical treatment, electronics, chemicals, medicine and laboratory of universities and colleges.

ing, automobile reparation, gas analysis, medicine mechanism, printing mechanism and other vacuum evacuations.

◊ Technical data

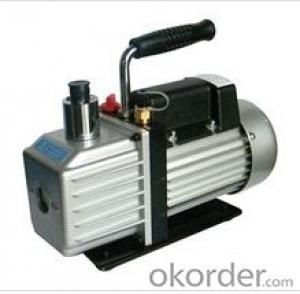

◊ Products' picture

- Q: What are the uses and precautions of magnetic pumps?

- 5, after the motor starts, slowly open the drain valve, until the pump into the normal working state, and then discharge valve to the desired opening;6, before the pump stops working, should first close the exhaust valve, and then turn off the suction valve.

- Q: The function of centrifugal pump

- 4, bearings are set on the pump shaft supporting the pump shaft components, there are two kinds of rolling bearings and sliding bearings. Rolling bearings use butter as a lubricant, refueling should be appropriate, generally 2/3 ~ 3/4 of the volume is too much, will heat, too little, there is noise and fever! The plain bearings are made of transparent oil as a lubricant and fill up to the oil level. Too much oil will leak out along the pump shaft and float *, too little, the bearings will overheat and burn out, causing accidents! In the pump running process, bearing temperature is highest in 85 degrees, generally run at about 60 degrees, if higher, will find the reason (whether there is impurities, whether the oil is black, whether water) and timely processing!

- Q: What is the minimum continuous flow of a pump?

- The minimum continuous steady flow can be obtained by test and, in general, the pump supplier will indicate(2) minimum continuous heat limited flow (.API) provides minimum continuous heat limit flow, which means the minimum continuous flow that the pump can maintain and that its operation is not impaired by the temperature rise of the liquid being pumpedMinimum continuous heat limited flow can be calculatedIn the formula, the Pe amount of the fixed axis power is.KW;P pump medium density, kg / m3;

- Q: If the suction pump does not have enough suction range, you need to add a vacuum pump to increase the suction stroke. How do you install the suction pipe of the vacuum pump? Water pump impeller is not closed, it is normal that the vacuum pump is unable to pump suction pipe to a vacuum, is it because the water pump outlet pipe connected to the role of the check valve? But the water pump, outlet pipe, check valve sealing performance can achieve the function of non leakage?

- Vacuum suction principle of self suction pump:Assuming that the pump connected with the water inlet of a sealed container, the container has plenty of water, since the start of a water pump, water is thrown out of the water impeller pump body, water inlet seal vessel due to the extraction of water to form a vacuum cavity, this assumption will be connected to vacuum cavity and exposed to atmospheric conditions of water, water at atmospheric pressure under the effect of entry into the vacuum chamber".

- Q: What are the application areas of pumps?

- 1, urban water supply 2, sewage system 3, civil and construction systems 4, agricultural water conservancy system 5, power station system6. Chemical system 7, petroleum industry system 8, mine metallurgy system 9, light industry system 10, ship system

- Q: What kind of motor does the hydraulic pump need?

- First count the flow: Q=dn L / minD displacement / revN RPM / minThen calculate the actual power: N=QP/ (60K) kwQ flow L / minP MPa MPaK total efficiency (usually 0.85)

- Q: Pump operator's responsibility 10Sharing the rules, responsibilities, etc..

- 3. master the operating rules of the pump operation, and make sure the pump position is reasonably determined. Do a good job of site investigation, find out, pay attention to.4. master the working principle and basic technical parameters of the delivery pump. Obey the command of production dispatcher to ensure the completion of production tasks.5., according to the number of tanker at the scene, determine the pumping speed, in order to ensure the continuity of pouring.6. normal pumping, the discharge rate should be uniform, to prevent uneven discharge, resulting in pressure pipe gas plug, and thus lead to pipe or pipe explosion accident.

- Q: I want to know the concrete under 60 type pump performance, it is mainly the pump long spiral bored piles, such as the diameter of the pump, transportation distance, pumping height and so on, thank you!

- Specification for concrete cylinders:Bore * stroke mm 200 * 1650Hopper capacity L 800Feeding height mm 1400Motor model Y2-280M-4Power kw 90Rated voltage V 380Rated speed r/min 1480Soft starter withoutHydraulic system open-loop

- Q: The working principle of magnetic pump

- Magnetic pumpBy the pump magnetic pump, magnetic actuators, motors of three parts. The key components of magnetic actuator by the external magnetic rotor sleeve, inner magnetic rotor and non magnetic components. When the motor drives the outer magnetic rotor, the magnetic field can penetrate the air gap and non-magnetic material, driven by the inner magnetic rotor is connected with the impeller for synchronization the rotation, to achieve non-contact power transmission, the dynamic seal into static seal. As the shaft, the rotor is within a magnetic pump, isolated sets of completely closed to completely solve the problem of "run, run, drip, leak, remove the oil refining chemical industry flammable, explosive, toxic and harmful media through the pump seal leakage security risks, effectively ensure the health and safety of workers.

- Q: What's the word "pump"? Is that what advocates mean?RT

- Is generally believed that the "wholesale" is the "hoarding" of "hoarding" variant, can be used to replace the word "store". And "wholesale" compared to "store" is clearly better and better recognize, because the "store" is a phonogram, hoard shaped characters "mouth", said the biggest the range of aggregation, like a grain bin; "Tun" is also phonetic, semantic. Tun, originally refers to the grass speared out of shape, with curly tails, and gathered the meaning.In this case, the "fans" can be written as "Yong Tun". But this is also troublesome, because the "store" in addition to read "Tun" (Ping Sheng), another pronunciation of "Dun" (Qu Sheng), who said food utensils, when we had the "Valley" store. So, if the "fans" to "hold", is also wrong. "Bin Zhao Wei fans" although it sounds strange, but at least not ambiguous; if changed to "Zhao Wei", is that we have to hoard may hear "Zhao Wei" or "Zhao Wei hold hip", hold the shield this is not the more the more chaotic change it!It is suggested that the "fans" to "fantastic", the modified method was acceptable. In modern Chinese, "public" does not necessarily mean that many, can also refer to a single. "One of the masses", "one of the audience (or audience)" this kind of argument, has been about good. Since this kind, we say "a fantastic" what not? "Fantastic" at least than the "fans" straightaway. The problem is, the word and Hong Kong Standards, there is no "fantastic".

Send your message to us

Double Stage Chemical Industry Vacuum Pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords