DIFFERENT Edge Banding Machines CHINA MARKET

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Edge Banding Machines-Panel Saw Description

A panel saw is any type of sawing machine with a sliding table that cuts sheets into sized parts.

A sliding panel saw was invented by Wilhelm Altendorf in 1906 in Germany. Its invention set a new standard in woodworking, with dramatic differences from traditional machines. Up to that time, a conventional table saw had no mechanism for edging. Meaning that for the first and second longitudinal cut on untreated massive wood, the lumber always had to be fed manually through the saw blade. The new system accomplished the task more elegantly by allowing the work piece to be fed through the saw blade while lying on a sliding table. Thus cutting becomes faster, accurate and effortless.

2.Main Features of Edge Banding Machines-Panel Saw

Panel saws are used by cabinet shops to easily cut panels, profiles, solid-wood, MDF, laminates, plastic sheets and sheets into sizes or cabinet components. They are also used by sign shops to cut sheets of aluminum, plastic and wood for their sign blanks. Some higher end panel saws feature computer controls that move the blade and fence systems to preset values. Other lower end machines offer simplicity and ease of use, including full scale hobbyist level panel saws at a mere fraction of the cost. While the entry level machines are designed for light duty usage, they offer home DIYers a cheap alternative for infrequent cutting when accuracy and clean cuts are not required.

Panel saws can have one main saw blade, or a scoring along with a main saw blade. Scoring is used to create a groove, especially in double side laminate before the main saw rips the piece apart, to avoid chipping. The scoring saw rotates in an opposite direction, as the main saw to avoid chipping.

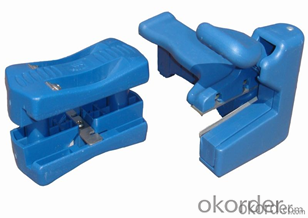

3.Edge Banding Machines-Panel Saw Images

4.Edge Banding Machine-Panel Saw Specifications

Maximum cutting length2800mm2800mm

Maximum cutting thickness80mm80mm

Main Blade sizeΦ305×Φ30mmΦ305×Φ30mm

Slot Blade sizeΦ120×Φ22mmΦ120×Φ22mm

Main saw shaft speed4000/5000rpm4000/5000rpm

Slot saw shaft speed9000r/min9000r/min

Main saw motor power5.5kw4kw

Slot saw motor power1.1kw1.1kw

Total power6.6kw5.1kw

Suction mouthΦ100×1Φ100×1

Weight800kg770kg

Box set dimensions3400×1150×1100mm3400×1100×1100mm

5.FAQ of Edge Banding Machines-Panel Saw

1) What can we do for you?

.We can ensure the quality of the Edge Banding Machines-Panel Saw and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: What is the PVC banding strip for?

- The utility model is mainly used for sealing edges of furniture, and can play the role of beauty and protection

- Q: Has any friend ever used an automatic curve edge sealing machine?

- 13 years in the Lunjiao Woodworking Machinery Exhibition saw manufacturers just don't remember

- Q: Do the overall wardrobe, piecework wages can count to how many square meters, blanking, edge banding, drilling, all the procedures should be considered?

- The minimum material should be opened 12 yuan, or else no one to help you do, the next is critical, the master of the process is not in place, the waste of relatively large plate, so good master, the money is also more expensive.As for the edge, about 8 yuanRow hole, 7 yuanTrial assembly: 22-25 yuan / flatInstallation: 32-35 yuan / flatThe total cost will be around 80-90 yuan per square meterThe above is for reference only:

- Q: Hong Fei edge edge machine always stop machine

- Not ah, this machine does not understand, it will not make the technology is not in place, definitely

- Q: What's the adhesive tape for the desk edge? What glue do you use?

- Structural adhesive, carpentry glue

- Q: Ask everybody a thing, how much is that cloth sealing edge strip one meter?

- Plastic edge banding, such as 1*22, is your price into a figure of 0.45, imports are not expensive you buy, wardrobe is 2*30, it is not so expensive

- Q: Line edge to use what glue

- White latex or foam gum can be used.1, this depends on what the edge material is used, the general edge of the material does not need glue, directly with foam glue on the line, such as non solid wood edge material, foam adhesive can be good.2, if you want a better effect, you can use white latex, and some solid wood edge material, with white latex treatment more fine, longer service life.3, of course, buy edge banding material is optional adhesive.

- Q: PVC what's the glue for the edge banding?

- Some plants use glue glue, some glue with hot melt glue, glue we have, welcome to contact

- Q: I am a furniture factory, need a lot, it is best to paint to dry is the best, the ash inside the shop, if the dry time is too slow for local repair will be dust, it will look at the dust, affect the quality of the product.

- Is the seal broken? Paint and paint is not the same, to go inside with the infiltration density board paint, fill the effect is not good, to what the people network to find a professional furniture repair.

- Q: Why does our family seal edge fall off, cabinet experience deformation?

- Lumber is bad, damp, when water evaporates, cause plate deformation

Send your message to us

DIFFERENT Edge Banding Machines CHINA MARKET

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 5000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords