Dead-Burned Magnesite Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

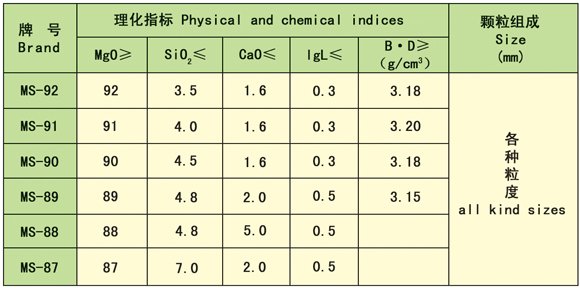

| Place of Origin: | Liaoning, China (Mainland) | Shape: | Block | SiO2 Content (%): | 3.5-7.0 |

| MgO Content (%): | 87-92 | CaO Content (%): | 1.6-5.0 | Model Number: | M-DBM |

| Brand Name: | CNBM |

Packaging & Delivery

| Packaging Details: | 10-25kilogram 5 layers craft paper bags, the craft paper and plastic compound bags; 40-50 kilograms PP bag, 500 and 1000 kilograms PP bag packing. We can also pack according to users' requirements |

| Delivery Detail: | Within 1 month |

Specifications

1.High purity Large crystal grain Compact structure

2.Strong resistance to slag material

3.Good thermal shock resistance

Dead-burned magnesite is selected from natural magnesite, it is produced by mine-selecting, purifying, calcining in shaft kiln. It is an ideal material for unshaped refractory material, the final products are used in open hearth furnace, eletric furnace bottom and furace's lining tamping.

Details are as follows:

Our company has processed various kinds of magnesia. As 20 years passing, our products of magnesite are widely used in many industrial fields of areas the world. Any question, please feel freely to contact us.

Magnesia is divided into sintered magnesia, light burned magnesia, fused magnesia three categories.Magnesia refractory material is one of the most important raw materials, aluminum used in the manufacture of all kinds of magnesite brick, magnesite brick, ramming material, repairing, etc.Contain a more impurities, are used to construct steel furnace bottom, etc.Sand in the main ingredients for magnesium oxide, impurities such as CaO, SiO2, Fe2O3, magnesium oxide as basic oxide, melting point is 2800 degrees, after the high temperature heating into stable cubic crystal, commonly known as periclase.By magnesium hydroxide by high temperature calcination, hydration resistance ability.Sintered magnesia is mainly composed of magnesite, magnesite or water from the water extract of magnesium hydroxide by high temperature calcination.Hydration resistance ability.Magnesite calcination under 700-950 ℃ is escaping CO2, magnesite as soft porous loose material, cannot be used for refractory material;Magnesite through 1550-1600 ℃ calcination so-called burned magnesia said sintered magnesite.Light burning magnesium powder is bending, compression, high strength, hard, gelled material, widely used in national defense, medicine, chemical industry, paper making, shipbuilding and other industries.In the building materials industry produce tire sub board, particle board, heat preservation columns, railing, artificial marble, asbestos tile, ordinary tiles, wall panel, laying on the ground.With the progress of science and technology, light burning magnesium powder application more widely, civil products, light and heavy machinery packing boxes, packaging can do sill, high-temperature refractory material, also can make beautiful luster strong furniture, in the machinery industry to do model.

- Q: What is the importance of silicon powder in refractory processing?

- in amorphousness it is mainly the mobility

- Q: How to solve the shell, the crack problem of refractory material in the process of forming.

- Pressure mode and number of pressure control "spallation". 2, multiple pressure, pressure degree and discharge way: 1, reduce friction, choose appropriate, than big pressure disposable pressure produced by the plastic deformation, allocate reasonable grading, internal and external friction, reduce billet particles and high die wall bright. 4.--- solve the light one firstly. --moisture content being too high easily cause spallation - the compressibility of water is small and have certain elasticity, appropriately to extend the pressuring time is beneficial. The material can produce large plastic deformation under the effect of continuous load. The right amount of lubricant. - body under the condition of less pressure but long effect time molding. Mould structure is reasonable and improve billet natural stacking density. 5.3, measures to improve the unburned brick molding quality. Many times continuously pressure relief is better than one-off sudden unloading, and controlling the appropriate moisture content;- - is beneficial to air overflow.

- Q: What are the basic requirements of continuous casting for molten steel? What are the requirements for refractory materials?

- The rapid development of the technology of continuous casting refractories so the corresponding development and improvement in variety and quality, continuous development of refractories for the continuous casting billet continuous casting production and quality have a significant impact. Especially, the completion and operation of Baosteel have greatly promoted the technological progress of refractory materials in China, and the refractory materials for continuous casting have made great progress both in variety and in quality.

- Q: Can anyone say something about the curtain wall fire-proof material key sealing point?

- Keypoints; 1, curtain wall design must consider the safety requirements, one of which is fire protection design. 2, Generally, fire protection planning between curtain walls should use the method of setting fireproof isolation layer. 3, Two layers of fireproof isolation layer whose thickness should not be less than 100mm respectively on the top edge and lower edge of the material parts of the house. 4, the fireproof isolation layer commonly uses 1.5mm thick galvanized steel sheet as supporting plate, using for shelving fireproof sheet. The 100mm thick cavity between the layers is filled with mineral wool non-combustible materials tightly covered with tinfoil on the surfaces. 5, protective isolation layer should try to reconcile curtain wall beam level and finish floor level, so as to fill non-combustible material and to avoid that a piece of glass acrosses two fire?compartments. 6, the beam should be inside 100mm thick fireproof isolation layer to protect the beam and the upper curtain wall plate. 7, when there are open fire function areas like large-scale hotel or restaurant kitchen inside the curtain walls, curtain wall glass in these parts should consider using cesium potassium fireproof glass to improve the fireproof rating in the region. 8, Fireproof setting in the around areas of curtain wall can use the same method of the above fireproof setting between layers. The joint parts of fireproof isolaton layer and main part as well as curtain wall should use fireproof sealant to seal.

- Q: What is the use of refractory?

- It is fire-retardant and insulated.

- Q: What needs to be noted when choosing and using blast furnace fireproof materials? Who knows?

- there are different temperatures in various parts of the blast furnace, thus using different types of refractory.

- Q: Development trend of refractory industry

- In the central provinces in Henan, Shanxi, Liaoning China main manufacturer of refractory material, which is the main origin of three China bauxite, magnesite and other refractory materials; refractories industry by the end of May 2009 more than 3236 enterprises; industry revenue reached 67 billion 52 million 540 thousand yuan, Henan Province, Liaoning, Shandong, Jiangsu, Hebei and other regions, and refractories industry in the development of better leading enterprises, such as blue and white, accessible, prco etc. at present, its sales in the industry in the proportion is still small, the largest sales is also inadequate in refractory industry in 4%. An enterprise should play a leading role in leading enterprises in the industry, and its turnover in the industry should be more than 15%. Obviously, at present the refractory industry in the leading enterprises do not have, and the refractory industry concentration needs to be improved, and the existing resources in the refractory industry integration, is undoubtedly the way this process effective and efficient.

- Q: On the problem of making refractory materials

- I think D is more appropriate, really want to choose ad can also.

- Q: What is the fireproofing requirements of external wall thermal insulation materials?

- External wall thermal insulation materials fire rating regulations, 1, the height of a building is greater than or equal to 100m , the combustion performance of insulation materials should be level A; 2, the height of a building is greater than or equal to 60m but less than 100m, the combustion performance of insulation materials should not be less than the level B2. When using level B2 thermal insulation material, every layer should set horizontal fire barrier zone 3,The height of building is be equal or greater than 24m but less than 60m, the combustion performance of thermal insulation material should not be less than the level B2. When using level B2 insulation material, each two-layer should set fire barrier zone ; 4, the height of building is less than 24m, the combustion performance of insulation materials should not be less than the level B2. Besides, when using level B2 thermal insulation material, each three-layer should set a horizontal fire barrier zone.

Send your message to us

Dead-Burned Magnesite Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords