Damascus Steel Billet for Producing Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Damascus Steel Billet for Producing Building Material

Specification of Damascus Steel Billet

Grade: mild steel 3sp 4sp 5sp

Dimensions: 100mmx100mm

Standard: AISI, ASTM, BS, DIN, GB, JIS, steel billet

teel billet length:: 3m-12m

billet steel grade:: 3sp 4sp 5sp q235 q195 q255 q275 20mnsi

Main Features of Damascus Steel Billet

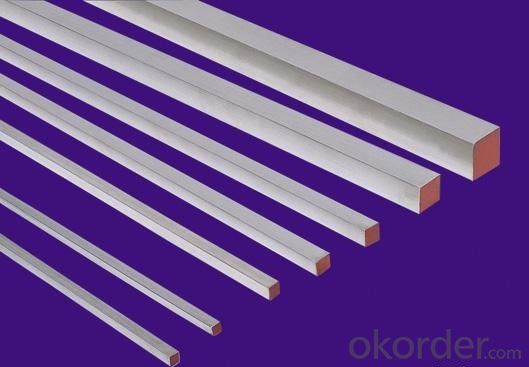

| Type : | Square steel billet |

| Steel Grade: | 3sp 5sp q195 q235 q255 q275 20mnsi ,astm a615 gr.60 |

| Size: | 60x60mm-150x150mm |

| Length: | 2m-12m . |

| Processing: | Hot rolled continous cast. |

| Application: | Wire rod , rod , deformed bars , profile steel , mechine parts , and steel mould ect . |

| Packing: | Loose Packing. |

| MOQ: | 1000Tons |

| Delivery Time: | 25days |

| Payment: | T/T , L/C,West Union , Cash . |

| Trade term: | FOB, CFR, CIF ,EXW. |

| Trans term: | FIO ,FILO ,FLT. |

Datas for Damascus Steel Billet

Steel billet Steel Grade C(%) Mn(%) Si(%) P(%) S(%) Q235 ≤0.20 ≤1.40 ≤0.35 ≤0.045 ≤0.045 Q275 ≤0.22 ≤1.50 ≤0.35 ≤0.045 ≤0.045 20MnSi 0.17-0.25 1.20-1.60 0.40-0.80 ≤0.050 ≤0.050 3SP 0.18-0.22 0.60-0.85 0.05-0.30 ≤ 0.040 ≤0.050 5SP 0.28-0.37 0.80-1.00 0.15-0.30 ≤ 0.040 ≤0.050

FAQ

Q:Why should choose us?

A:Stable quality ----continous casting hot rolled production techenic, strictly quality control system.

Lower price -------Not the cheapest but the lowest price at the same quality .

Good service -----Satisfactory service within 24hours.

Delivery time ------15-25days for the mass production .

Discount---------------discount base on monthly large quantity purchase in long term.

Pictures:

- Q: How are steel pipes used in the manufacturing of wastewater treatment systems?

- Steel pipes are commonly used in the manufacturing of wastewater treatment systems due to their durability, strength, and resistance to corrosion. They are used for various purposes such as transporting wastewater from one unit to another, constructing storage tanks and pipelines, and supporting the infrastructure of the treatment plants. Steel pipes are able to withstand the harsh conditions of wastewater environments, ensuring long-lasting and reliable performance of the treatment systems.

- Q: How are steel pipes measured and labeled?

- Steel pipes are typically measured and labeled based on their outside diameter (OD) and wall thickness. The measurement is usually expressed in millimeters or inches. The label includes these dimensions, such as "2-inch OD, 1/8-inch wall thickness." Additionally, the length of the pipe may also be included in the labeling, ranging from standard lengths like 6 meters or 20 feet.

- Q: How do you determine the maximum allowable stress for steel pipes?

- To determine the maximum allowable stress for steel pipes, several factors need to be considered. These factors include the type of steel, the pipe's dimensions, and the operating conditions under which the pipe will be used. Firstly, the type of steel plays a crucial role in determining the maximum allowable stress. Different grades of steel have varying mechanical properties, including yield strength, tensile strength, and elongation. These properties define the material's ability to withstand stress before deformation or failure. Therefore, understanding the specific grade of steel used in the pipes is vital in determining the maximum allowable stress. Secondly, the dimensions of the pipe are essential. The outer diameter, wall thickness, and length all influence the pipe's strength and ability to handle stress. By calculating the cross-sectional area and moment of inertia, engineers can determine the pipe's resistance to bending and axial stresses. These calculations, along with the material properties, help establish the maximum allowable stress. Lastly, the operating conditions under which the pipe will be subjected to are critical. Factors such as temperature, pressure, and the presence of corrosive substances can significantly impact a steel pipe's maximum allowable stress. Elevated temperatures can affect the steel's mechanical properties, while high pressures can induce additional stress. The presence of corrosive substances can lead to material degradation and decrease the pipe's strength. Considering these operational factors is crucial in determining the maximum allowable stress. To sum up, determining the maximum allowable stress for steel pipes involves considering the specific grade of steel, the pipe's dimensions, and the operating conditions. By analyzing these factors, engineers can ensure that the steel pipe is designed and used within its safe stress limits.

- Q: How are steel pipes used in the manufacturing of offshore wind turbines?

- Steel pipes are used in the manufacturing of offshore wind turbines for various purposes. They are commonly used to create the foundation structures, such as monopiles and jacket structures, which provide stability and support for the turbines in the seabed. Steel pipes are also utilized for the construction of the tower and nacelle structures, providing a strong and durable framework for the turbine components. Additionally, steel pipes are employed for the installation of subsea cables, allowing for the transmission of electricity generated by the turbines to the shore. Overall, steel pipes play a crucial role in the manufacturing of offshore wind turbines by providing the necessary strength, stability, and infrastructure required for their operation.

- Q: What is the difference between steel pipe and tubing?

- Steel pipe and tubing serve various purposes, but they possess distinct dissimilarities. The fundamental distinction between them stems from their shape and dimensions. Steel pipe, ordinarily circular in shape, features a hollow interior. It is manufactured in a range of sizes and thicknesses to accommodate diverse pressure and temperature prerequisites. Steel pipe frequently finds employment in construction, plumbing, and the oil and gas industries for the conveyance of fluids or gases. Conversely, steel tubing can adopt a variety of shapes, such as circular, square, and rectangular. Unlike steel pipe, tubing is typically evaluated by its outer diameter and wall thickness. Structural applications, such as building frames, automotive components, and machinery, often employ steel tubing. Another divergence between steel pipe and tubing lies in their manufacturing processes. Steel pipe is typically fashioned from solid steel billets, which are heated and stretched to produce a seamless or welded tube. On the other hand, tubing can be generated through diverse methods, including hot or cold rolling, welding, or extrusion. In terms of strength and durability, both steel pipe and tubing offer excellent qualities. Nevertheless, the particular requirements of the application will dictate which one is more suitable. Steel pipe is frequently selected for high-pressure or high-temperature applications, whereas steel tubing is favored for structural purposes or when a specific shape is necessary. In summary, the primary disparity between steel pipe and tubing resides in their shape, measurement techniques, and manufacturing procedures. While steel pipe possesses a round shape and is measured by its inner diameter, tubing can adopt various shapes and is usually measured by its outer diameter. Both steel pipe and tubing find extensive use in diverse industries, but the choice depends on the specific application and requirements.

- Q: Are steel pipes suitable for underground cable protection?

- Yes, steel pipes are suitable for underground cable protection. Steel pipes provide excellent durability and strength, making them ideal for protecting cables from external factors such as physical damage, moisture, and corrosion. They are able to withstand the weight of the soil and any potential pressure from above, ensuring the cables remain secure and protected. Additionally, steel pipes can be easily welded or connected to create a continuous and seamless conduit, further enhancing their effectiveness in underground cable protection.

- Q: What are the different types of steel pipe fittings for chemical processing plants?

- There are various types of steel pipe fittings commonly used in chemical processing plants, such as elbows, tees, reducers, couplings, flanges, and valves. These fittings are designed to connect and redirect the flow of fluids within the piping system, ensuring efficient and safe operation in chemical processing applications.

- Q: What are the different methods of joining steel pipes without welding?

- There are multiple ways to connect steel pipes without welding. These include: 1. Mechanical Couplings: These couplings consist of two separate pieces that attach to the pipe ends and then tighten together. They provide a secure and leak-proof connection, eliminating the need for welding. 2. Threaded Connections: This method involves threading the ends of the steel pipes to create a male and female connection. The pipes are then screwed together using pipe threads, creating a strong and dependable joint. 3. Flanged Connections: Flanges are utilized to connect steel pipes by bolting them together. The flanges have a flat surface with holes that align with corresponding holes in the opposing flange. Bolts are inserted and tightened to establish a tight seal. 4. Grooved Connections: This technique involves grooving the pipe ends and using grooved couplings to join them. The couplings have teeth that interlock with the grooves, resulting in a secure and rigid connection. 5. Compression Fittings: Compression fittings are employed to connect steel pipes by compressing a metal or plastic ring onto the outer surface of the pipe. This creates a tight seal and a reliable connection without welding. 6. Adhesive Bonding: Special adhesives designed for bonding metals can be used to connect steel pipes. The adhesive is applied to the pipe surfaces, which are then pressed together and left to cure, forming a strong and durable bond. 7. Clamping: Clamps can be used to hold steel pipes together, creating a temporary connection. This method is commonly used for testing purposes or in situations where the pipes need to be easily dismantled. Each of these methods has its own benefits and limitations, and the choice depends on various factors such as the specific application, pipe material, and required joint strength.

- Q: What is the maximum length of a steel pipe?

- The maximum length of a steel pipe can vary depending on several factors such as the manufacturing process, transportation limitations, and structural requirements. However, in general, steel pipes can be manufactured in lengths up to 80 feet or more.

- Q: What are the different types of expansion joints used with steel pipes?

- There are several types of expansion joints used with steel pipes, including bellows expansion joints, universal expansion joints, hinged expansion joints, and gimbal expansion joints. These expansion joints are designed to accommodate the movement and thermal expansion of steel pipes, ensuring their integrity and preventing damage.

Send your message to us

Damascus Steel Billet for Producing Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords