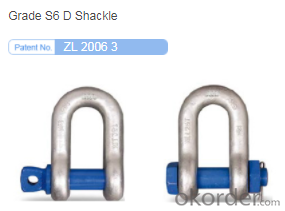

D-Shackle,It is made of high quality alloy steel by die forging.

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forging Rigging

SHACKLES

The forging rigging factory 。 is the largest production base for forging rigging in Asia with advanced forging, heat treatment,surface coating and nondestructive testing equipment and the most advanced production technology.

Main forging equipment :5T size free forging hydraulic hammer,4000t、2500t、1000t size friction press machine and 750kg ~ 1000kg size air forging hammer etc. We also researched and developed 400t、1000t、1500t、2000t size bending machine. The annual producing

capacity is 20000t.

The shackles (both body and pin) we produce are made of high quality alloy steel through advanced production line and intermediate frequency furnace heat treatment. It is characterized by high-intensity, good toughness, small volume, light weight, beautiful appearance and good durability.

Product category: Flat shackle, Large WLL shackle with circular cross-section, Bow shackle, D shackle etc.

Production range: 0.5t-2000t

It is made of high quality alloy steel by die forging.

Each shackle will be marked with WLL permanently, WLL from 0.5t ~150t.

The Maximum testing load is twice of the working load ,while WLL is less than 85t(including),the minimum breaking load is 6 times of the WLL ,while WLL is more than 85t ,the minimum breaking load is 4 times of WLL .

Our products all correspond with the stipulated technical requirement and test approach in standard ISO2415-2004.

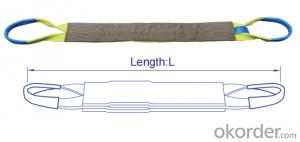

- Q: What tools are slings in lifting operations? What is the function of the slings?

- Sling made forms are more commonly used in engineering with inserting end ring and inserted nonpolar (Universal) slings in hoisting work are the steel wire rope is connected with a hook, shackle, sling made of various styles, for lifting, or binding.

- Q: Where should I pay attention to the formwork?

- When the interlayer height is greater than 5m, the truss formwork or the multi layer support formwork should be adoptedWhen the formwork is supported by a multi layer support, the support plate shall be smooth, the support shall be vertical, and the upper and lower support shall be on the same rigid central line.(5) when the segmental demoulding is adopted, the pivot of the bottom die shall be designed according to the template, and the sections shall be in the same plane, and the height difference shall not exceed 3mm.

- Q: What torture refers to the lever and the sling

- The suspension is the most commonly used methods of torture, victims of arms, body weight (including torture may also put the weight of the wrist) pull out there will be pain, at the same time due to pleural retraction deformation, suspension long time can cause suffering breathing difficulties.Use the upside down way, will make the victims head congestion, long time down there may be a bloody situation (jiangzhujun inmates had been hanged for a long time and fainting).To increase traction pain, the use of hanging is often tied hanging victims two thumb or toe (upside down when used), other phalangeal joints due to withstand the weight of a body is completely broken because. The famous Vietnamese Female Valhalla Chen cloud was torturer stripped naked, tied with wire two big toe hung upside down and beaten.

- Q: The wire rope lock can hang a lot of things

- 2. galvanized steel wire rope, including hot-dip galvanizing and electro galvanized two, in general, hot galvanized zinc layer thickness, zinc plated zinc thin3. stainless steel wire rope, 304 or 316 stainless steel based, anti-corrosion effect is very good, but expensive4. carbon coated steel wire rope, wire rope based on polyethylene, polypropylene or nylon outer coating5. smooth wire rope, short service life, sharp decline in market demand, will be phasing out the phosphating coating steel wire rope.

- Q: What are the installation steps for crane beams?

- Installation of crane beam elevation as a negative deviation, between surface and column bracket crane beam flange into the iron plate. But the shim shall not exceed three layers and shall be placed under the end of the crane beam or under the stiffener, and the area of the shim shall not be less than 60% of the part of the contact area between the crane beam and the bracket.

- Q: What are the specifications for the length, length, and method of operation of the wire rope?

- The fatigue life is three times the same structure of plain steel wire rope, the highest value of contrast test has reached an alarming four times, can be verified by fatigue test, fatigue life ability if they have on their own to do comparative experiments, this test results the most credible, the service life of wire rope and the fatigue life is proportional to a long fatigue life use the same proportion of life extension, the use of lower cost, better stability.

- Q: What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 4. coated steel wire rope, the carbon steel wire rope based on the rope or rope coated with polyethylene or polypropylene5. smooth wire rope, in 1834 the British began production in China in 1939 started production in Tianjin No.1 steel wire rope factory, with the phosphating coating steel wire rope into the market size gradually increased, will be fully replace phosphating coating steel wire rope.

- Q: Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- Finally, the gravity of the main beam becomes the two vertical force of the tower, so that the force passes to the pier under the tower.There are more cables, and the same reason. There are a lot of bars, that's to distract the main girder from the cables.As a kind of cable of cable-stayed bridge, more than beam bridge spanning capacity is the main bridge of long span bridges. The cable stayed bridge is composed of many cables which are directly connected to the tower. The cable-stayed bridge is composed of pylon, main beam and stay cable. The types of pylon are A, inverted Y, H and single column. The materials are steel and concrete. There are single cable plane, parallel double cable plane and inclined cable plane in the stay cable. The first modern cable-stayed bridge was built in Sweden in 1955 and has a span of 182 meters. At present, the largest span cable-stayed bridge built in the world is the Normandy bridge in France, with a main span of 856 meters. The Shanghai Yangpu bridge, built in 1993, is the largest cable-stayed bridge in China, with a main span of 602 meters

- Q: What are the specifications for the rigging?

- Because the demand is more difficult to buy, to ask the producer of several wire rope, please note in the purchase, purchase invoice must indicate the name of wire rope, such as phosphate coated wire rope, prevent illegal infringement of their legitimate rights and interests of enterprises, in addition, patent products are generally in the rope on the outer packing of a patent spraying mark, warranty due the main technical indicators, such as the phosphating film type and film weight (have an important impact on the weight of phosphating film size, wear resistance and corrosion resistance of the service life of the wire rope, for reference only)

- Q: Does the pressing rope have any influence on the tension value of the wire rope?

- Lifting equipment commonly used wire rope varieties of phosphating coating steel wire rope, galvanized steel wire, stainless steel wire rope or coated steel wire rope.

Send your message to us

D-Shackle,It is made of high quality alloy steel by die forging.

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords