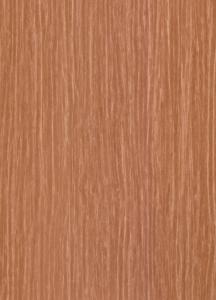

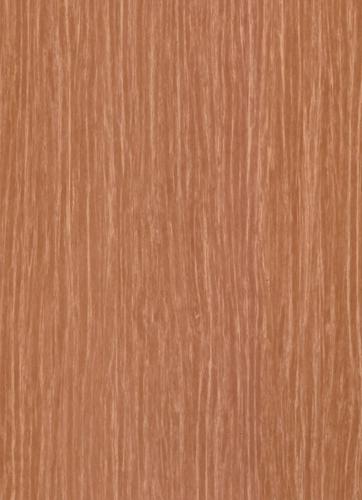

Customized Embossed Aluminum Coil with Wood Grain

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated sheetand coil choose aluminium sheet coil as raw material, after de-ester, cleaning,passivation layer processing, and then painting on this basis, the paint areprovided by famous international companies like PPG and Valspar from UnitedStates or Becker from Sweden, represent the most advanced level in the world.After the test of exposure by natural light in Florida, the quality assurance is more than morethan 20 years. As poor performance of color coated steel corrosion, rust,yellow rust after a large amount of the deficiency of serious impact on thebuilding's overall appearance. However, because of the advantages of rawmaterials, Aluminium coated coil have a high strength, corrosion resistance,high weather resistance, can be used recycle, save energy and protect theenvironment and other characteristics. Not only have the same strength with colorcoated steel, but also overcome the shortage of color coated steel. So, the Aluminiumcoated coil has been widely used as roofing and ceiling decorative envelopesystem board in modern constructions like large factories, exhibition halls,stadiums, airports, train station hospital and so on. We can choose Aluminiumcoated coil in different thickness and color, by cutting, pressing, punching,bending and other follow-up molding process for large span, the larger theoverall roofing, wall decorative panels used in construction; or cut them intosmall panels by bending, stamping mold or other processing for indoordecorative roofing plate; we can also composite them with polyurethane foam oraluminium honeycomb for energy-saving decorative wall plates.

Alloy | 1050,1060,1100,3003,3004,3005,3104,3105,5052,5005,8011 |

Temper | O,H42,H44,H46,H48 |

Thickness (mm) | 0.25mm-1.5mm for aluminium coated coil; 1.50mm-4.0mm for aluminium coated sheet. |

Width (mm) | 100mm to 2000mm |

Length (mm) | 800mm to 6000mm for sheet |

- Q: What are the potential applications of coil-anodized aluminum coils?

- Coil-anodized aluminum coils have a wide range of potential applications due to their durability, versatility, and aesthetic appeal. Some of the common applications include architectural cladding, roofing, signage, facade panels, interior decoration, automotive trim, and electronics casings. The anodized coating provides enhanced corrosion resistance, weatherability, and color stability, making it suitable for both indoor and outdoor use. Additionally, the ability to create various finishes and textures further expands the possibilities for using coil-anodized aluminum coils in different industries.

- Q: How to calculate the wall thickness with the gross weight of aluminum coil known?

- Gross weight*density=volume volume÷(aluminum sheet *width)=thickness

- Q: Can aluminum coils be used for packaging applications?

- Indeed, packaging applications can make use of aluminum coils. Aluminum, being a versatile material, possesses various advantageous properties for packaging purposes. Its lightweight nature, resistance to corrosion, non-toxicity, and exceptional thermal conductivity are just a few of the many benefits it offers. These qualities render aluminum coils perfect for packaging applications such as food and beverage containers, pharmaceutical packaging, and cosmetic packaging. Moreover, aluminum can easily be molded into various shapes and sizes, allowing for tailor-made packaging solutions. Its durability ensures the safeguarding of the packaged goods, while its ability to be recycled makes it an environmentally conscious choice. In summary, the versatility, performance, and sustainability of aluminum coils make them extensively utilized in packaging applications.

- Q: What are the common surface defects found in aluminum coils?

- Some common surface defects found in aluminum coils include: 1. Scratches: These are visible lines or marks on the surface of the coil that can be caused during handling, transportation, or processing. Scratches can impact the appearance and functionality of the aluminum coil. 2. Dents: Dents are depressions or deformations on the surface of the coil. They can occur due to mishandling or impact during transportation or storage. Dents can affect the structural integrity and aesthetics of the aluminum coil. 3. Corrosion: Aluminum is susceptible to corrosion, especially in environments with high levels of moisture or exposure to chemicals. Corrosion can appear as pitting, discoloration, or roughness on the surface of the coil. It can weaken the coil and compromise its performance. 4. Streaking: Streaks are thin lines or bands that appear on the surface of the coil, often caused by uneven coating or surface contamination. Streaking can affect the visual appeal of the aluminum coil and may indicate a problem with the manufacturing process. 5. Oxide spots: Oxide spots are small, discolored areas on the surface of the aluminum coil, caused by the formation of aluminum oxide. These spots can occur due to oxidation during processing or storage. While they do not typically affect the performance of the coil, they can be aesthetically undesirable. 6. Oil stains: Oil stains are greasy or oily marks on the surface of the aluminum coil, often caused by improper cleaning or handling. These stains can affect the adhesion of coatings or paints and may require additional cleaning or treatment. 7. Roll marks: Roll marks are elongated depressions or raised lines on the surface of the coil, caused by the rolling process during manufacturing. While roll marks are generally unavoidable, excessive or severe roll marks can impact the appearance and quality of the aluminum coil. It is important to note that proper quality control measures, handling, and storage practices can help minimize or prevent these surface defects in aluminum coils.

- Q: The general roll also 5,6t appearance, specific to your own weigh, length, weight = / (width * thickness * density)

- The general roll also 5,6t appearance, specific to your own weigh, length, weight = / (width * thickness * density)

- Q: Can aluminum coils be used for food processing equipment?

- Yes, aluminum coils can be used for food processing equipment. Aluminum is a common choice for food processing equipment due to its excellent thermal conductivity, corrosion resistance, and lightweight nature. It is widely used in the food industry for various applications such as heat exchangers, evaporators, and condensers. Aluminum coils are specifically designed to efficiently transfer heat and maintain a stable temperature, making them suitable for food processing equipment that requires precise temperature control. Additionally, aluminum is a non-toxic material, ensuring that it does not contaminate the food being processed. Therefore, aluminum coils are a reliable and safe choice for food processing equipment.

- Q: Is it safe or effective to use a hot plate for heating an aluminum coil?

- <p>Yes, you can use a hot plate to heat an aluminum coil, but with caution. Aluminum is a good conductor of heat, so it will heat up quickly. Ensure that the coil is clean and free from any residues that might cause uneven heating or damage. Monitor the temperature closely to prevent overheating, as aluminum can warp or melt at high temperatures. Use a heat-resistant surface or a heat diffuser to distribute the heat evenly and protect the hot plate surface. Always follow safety guidelines and manufacturer recommendations for both the hot plate and the aluminum coil.</p>

- Q: This question asks about the applications of aluminum coil in the field of architecture.

- <p>Aluminum coil is widely used in architecture for various purposes. It is utilized in the manufacturing of aluminum composite panels, which are lightweight, durable, and have excellent weather resistance, making them ideal for facades and exterior cladding. Aluminum coil is also used in the production of roofing materials and rainwater systems due to its corrosion resistance and strength. In addition, it is employed in the creation of window frames and doors for its thermal insulation properties and aesthetic appeal. Furthermore, aluminum coil is used in the construction of structural components such as beams and columns, taking advantage of its high strength-to-weight ratio and recyclability. Its versatility and sustainability make aluminum coil a popular choice in modern architectural design.</p>

- Q: Can aluminum coils be used in the production of fire-resistant structures?

- Indeed, the utilization of aluminum coils is possible for the fabrication of fire-resistant structures. Being inherently fire-resistant and possessing a remarkably high melting point, aluminum emerges as an excellent substance for structures that necessitate endurance against elevated temperatures. In the realm of construction, aluminum coils are frequently employed to fulfill fire-resistant requirements, including roofs, walls, and insulation. Moreover, the lightweight and durability of aluminum further facilitate the installation and maintenance of fire-resistant structures.

- Q: How do aluminum coils contribute to thermal management?

- Aluminum coils play a crucial role in thermal management due to their excellent heat transfer capabilities. Aluminum has a high thermal conductivity, which means it can efficiently transfer heat from one area to another. This property is essential in various applications that require effective thermal management, such as air conditioning systems, refrigeration units, and heat exchangers. In air conditioning systems, aluminum coils are commonly used in the condenser and evaporator coils. The condenser coil dissipates heat from the refrigerant to the surrounding air, while the evaporator coil absorbs heat from the indoor air to cool it down. The high thermal conductivity of aluminum allows for efficient heat transfer between the refrigerant and the surrounding air, resulting in faster and more effective cooling. Similarly, in refrigeration units, aluminum coils are utilized in the evaporator coils to remove heat from the interior space. The aluminum coils help to extract heat from the refrigerated area and transfer it to the outside environment, maintaining a lower temperature inside the unit. Aluminum coils also find application in heat exchangers, which are used in a wide range of industries, including automotive, power generation, and HVAC. Heat exchangers are devices that transfer heat between two or more fluids, often with different temperatures. The high thermal conductivity of aluminum enables efficient heat exchange between the fluids, improving overall system performance and energy efficiency. Moreover, aluminum coils are lightweight and resistant to corrosion, making them highly durable and suitable for long-term use in harsh environments. These properties further enhance their contribution to thermal management by ensuring reliable heat transfer and reducing the risk of system failure or efficiency loss. In summary, aluminum coils are instrumental in thermal management systems as they facilitate efficient heat transfer, contribute to faster cooling or heating processes, and enhance overall system performance. Their high thermal conductivity, lightweight nature, and corrosion resistance make them a preferred choice in various applications where effective thermal management is essential.

Send your message to us

Customized Embossed Aluminum Coil with Wood Grain

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords