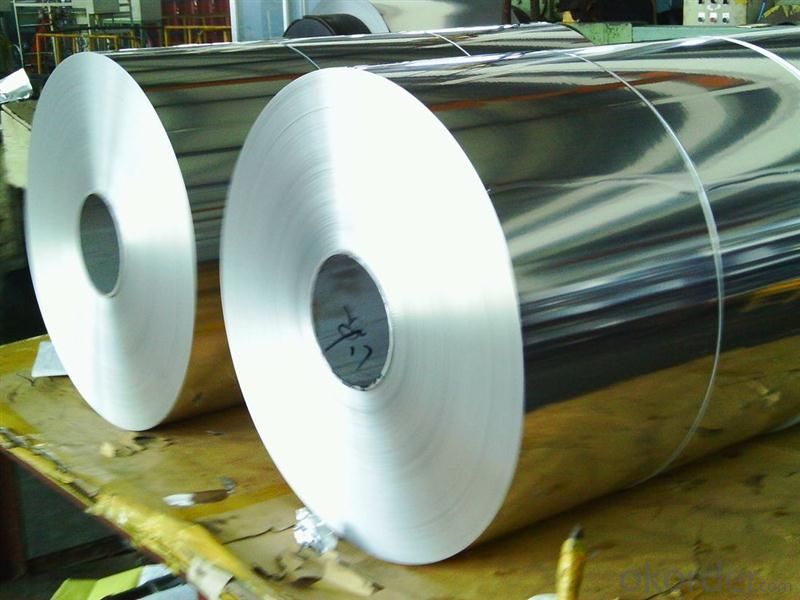

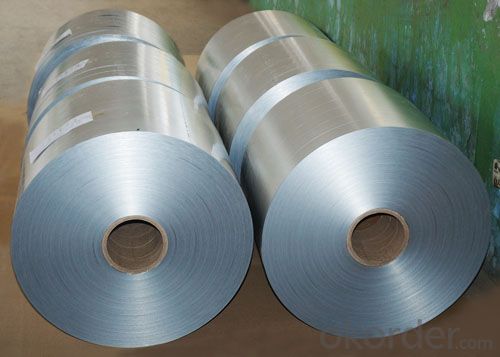

Custom Painted Aluminum Coil - 1100 Temper Ho 0.5mm 0.8m 1mm Thickness Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1100 Temper Ho 0.5mm 0.8m 1mm Thickness Aluminum Roll

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q: Can aluminum coils be used in food processing applications?

- Yes, aluminum coils can be used in food processing applications. Aluminum is a widely used material in the food industry due to its excellent thermal conductivity, corrosion resistance, and lightweight properties. Aluminum coils are commonly used in food processing equipment such as refrigerators, ovens, and food storage units to ensure proper temperature control and hygiene during food processing.

- Q: What are the common applications of aluminum coils?

- Aluminum coils are widely used in various industries due to their unique properties and versatility. Some of the common applications of aluminum coils include: 1. HVAC Systems: Aluminum coils are extensively used in air conditioning and refrigeration systems, where they play a crucial role in heat transfer. The lightweight and excellent thermal conductivity of aluminum make it an ideal choice for these applications. 2. Transportation Industry: Aluminum coils are commonly used in the automotive and aerospace industries. They are used to manufacture radiators, condensers, evaporators, and other heat exchange components in vehicles. The high strength-to-weight ratio of aluminum helps in reducing the overall weight of the vehicle, leading to improved fuel efficiency. 3. Construction Sector: Aluminum coils find extensive use in the construction industry. They are used in the production of gutters, downspouts, roofing, and cladding materials. Aluminum's corrosion resistance and durability make it a preferred choice for outdoor applications that require long-lasting performance. 4. Electrical Industry: Aluminum coils are used in the production of cables and wires due to their excellent electrical conductivity. They also find use in transformers and power distribution systems. 5. Packaging Industry: Aluminum coils are widely used in the packaging industry. They are used to produce various types of packaging materials, such as cans, foils, and containers. Aluminum's ability to form a barrier against moisture, light, and oxygen makes it ideal for preserving the freshness and quality of food and beverages. 6. Marine Applications: Aluminum coils are used in the marine industry for manufacturing boats, ships, and other offshore structures. Aluminum's resistance to corrosion in saltwater environments makes it a suitable choice for these applications. 7. Industrial Equipment: Aluminum coils are utilized in various industrial equipment, including heat exchangers, condensers, and evaporators. Their thermal conductivity and corrosion resistance properties make them suitable for efficient heat transfer. In summary, aluminum coils have a wide range of applications across multiple industries, including HVAC, transportation, construction, electrical, packaging, marine, and industrial equipment. Their lightweight, excellent thermal conductivity, corrosion resistance, and durability make them a preferred choice for various applications.

- Q: Can aluminum coils be used in curtain wall systems?

- Curtain wall systems can indeed incorporate aluminum coils. The lightweight property, durability, and resistance to corrosion make aluminum a favored material for curtain walls. Shaping and forming aluminum coils is a simple task, enabling the creation of desired profiles for these systems. Moreover, aluminum offers a broad spectrum of colors and finishes, allowing for customization and design adaptability. The utilization of aluminum coils in curtain wall systems also presents energy efficiency advantages, thanks to the commendable thermal conductivity properties of aluminum. In summary, aluminum coils are a fitting and widely employed material for constructing curtain wall systems.

- Q: What is the typical heat transfer coefficient for aluminum coils?

- The typical heat transfer coefficient for aluminum coils depends on various factors such as the specific application, geometry of the coil, and the surrounding conditions. However, in general, aluminum has a relatively high thermal conductivity, making it an efficient conductor of heat. For forced convection applications, where a fluid such as air or water is used to transfer heat, the heat transfer coefficient for aluminum coils can range from 10 to 100 W/m^2K. This range is influenced by factors such as the flow rate, velocity, and temperature difference between the coil and the fluid. In natural convection scenarios, where heat transfer occurs due to the buoyancy-driven flow of air, the heat transfer coefficient for aluminum coils is typically lower, ranging from 5 to 25 W/m^2K. This lower coefficient is due to the slower movement of air and the reduced heat transfer effectiveness compared to forced convection. It is important to note that these values are general guidelines and can vary significantly depending on specific design considerations, material properties, and operating conditions. Therefore, it is recommended to consult specific heat transfer data or conduct detailed experiments or simulations to determine the precise heat transfer coefficient for a given aluminum coil application.

- Q: i have about 100lbs of aluminum blocks and scrap.

- WOW.......they must be worth sum money. Lucky you!!!!!!

- Q: How do aluminum coils contribute to sustainable and green building practices?

- Aluminum coils contribute to sustainable and green building practices in several ways. Firstly, aluminum is a highly recyclable material, allowing for the reuse of aluminum coils in various applications, reducing waste and conserving natural resources. Additionally, aluminum is lightweight, which reduces transportation energy and costs during installation. Furthermore, aluminum coils have exceptional durability and corrosion resistance, resulting in longer lifespan and reduced maintenance needs. This longevity contributes to the overall sustainability of buildings, as they require fewer replacements and repairs. Lastly, aluminum is an energy-efficient material, as it has excellent thermal conductivity, allowing for better insulation and reduced energy consumption for heating and cooling purposes. Overall, the use of aluminum coils promotes sustainability, resource conservation, energy efficiency, and reduced environmental impact in green building practices.

- Q: Can aluminum coils be used in curtain wall systems?

- Yes, aluminum coils can be used in curtain wall systems. Aluminum is a popular material choice for curtain walls due to its lightweight nature, durability, and corrosion resistance. Aluminum coils can be easily formed and shaped to create the desired profiles for curtain wall systems. Additionally, aluminum is available in a wide range of colors and finishes, allowing for customization and design flexibility. The use of aluminum coils in curtain wall systems also offers energy efficiency benefits, as aluminum has good thermal conductivity properties. Overall, aluminum coils are a suitable and commonly used material in the construction of curtain wall systems.

- Q: Can aluminum coils be used in electrical busbars?

- Yes, aluminum coils can be used in electrical busbars. Aluminum is a commonly used material for busbars due to its high electrical conductivity, low cost, and lightweight properties. Aluminum coils can be easily formed into various shapes and sizes to fit specific busbar requirements. Additionally, aluminum has good thermal conductivity, which allows for efficient heat dissipation in high current applications. However, it is important to consider the current carrying capacity, mechanical strength, and corrosion resistance of aluminum coils when selecting them for busbar applications.

- Q: What are the safety considerations when working with aluminum coils?

- When working with aluminum coils, there are several safety considerations that should be taken into account to ensure the well-being of workers and prevent accidents. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and protective clothing. This will help protect against cuts, abrasions, and burns that can occur while handling sharp edges or during the coil manufacturing process. Secondly, aluminum coils should be stored properly to prevent any potential hazards. They should be stacked in a stable manner, taking into consideration the weight and height of the stack. Additionally, coils should be stored in a well-ventilated area to prevent the accumulation of flammable gases or vapors. When working with aluminum coils, it is crucial to be aware of the potential risks associated with the material. Aluminum can be a combustible material, and certain factors such as high temperatures and contact with sparks or open flames can increase the risk of fire. Therefore, it is important to keep the work area clean and free from any flammable materials or sources of ignition. Moreover, aluminum coils should be handled with care to avoid injuries. They can be heavy and may require the use of appropriate lifting equipment or techniques to prevent strains or musculoskeletal injuries. Workers should be trained on proper lifting techniques and be aware of their physical limitations to prevent accidents. Furthermore, when cutting or shaping aluminum coils, it is important to use appropriate tools and machinery. Workers should be trained on the safe operation of these tools and machinery to prevent injuries. It is also important to regularly inspect and maintain the equipment to ensure its safe functioning. Finally, it is important to follow proper handling and disposal procedures for aluminum coils. This may include considering recycling options to minimize waste and environmental impact. Overall, safety considerations when working with aluminum coils include wearing appropriate PPE, storing them properly, being aware of potential fire hazards, handling them with care, using appropriate tools and machinery, and following proper handling and disposal procedures. By adhering to these safety measures, the risk of accidents and injuries can be greatly reduced.

- Q: Does anyone know if aluminum skateboards are good?

- I haven't seen one since the old QuickSilver-Silver Surfer(circa 1979). They look great, but they become useless when scratched. Which means....you can't really use them for anything. They're not as flexible as wood....and.......Wait until you get hit in the shin with an aluminum skateboard. Aircraft metal my(explicative deleted). My guess is they're inexpensive because they're trying to get the word out. The company owners probably no very little about skateboarding.

Send your message to us

Custom Painted Aluminum Coil - 1100 Temper Ho 0.5mm 0.8m 1mm Thickness Aluminum Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords