Quick Details

Standard: ASTM

Grade: CS C

Type: Steel Coil

Surface Treatment: Galvanized

Application: Commercial steel

Width: 600-1534mm

Length: Coil

Packaging & Delivery

| Packaging Details: | Oscillated wound: one coil per bundle, inner is the protecting humidity-proof wax paper. Medium is plastic film. Outer is sackcloth or compound paper packing. Coil to be laid on single type pallet (one pile per pallet) |

|---|---|

| Delivery Detail: | Depends on specification and order quanity. |

Feature

(1) Regular spangle, minimized spangle and skin-pass.(2) Chromate and Chromate-free passivation.

(3) Oiled and unoiled.

Drawing quality - DIN EN 10346 HDG Steel Coil

(1) Type of zinc coating finish: regular spangle, minimized spangle and skin-pass.

(2) Types of surface qualities: as coated surface, improved surface and best quality surface.

(3) Surface treatment: chemically passivated, chromate-free passivation, phosphate, anti-finger print, phosphateand, self lubricating film, and untreated.

(4) Type of oiling: oiled and unoiled.

(5) Coil ID: 508/610mm.

(6) Grade: DX52D+Z; Application: drawing use.

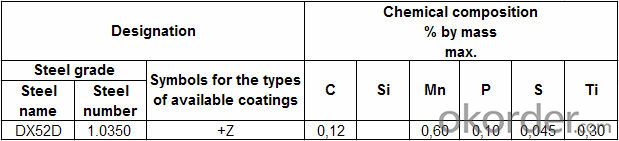

Chemcial composition (cast analysis) of low carbon steels for cold forming

Specifications

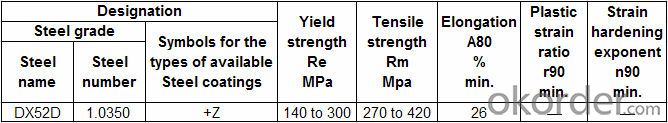

Mechanical properties (transverse direction) of low carbon steels for cold forming

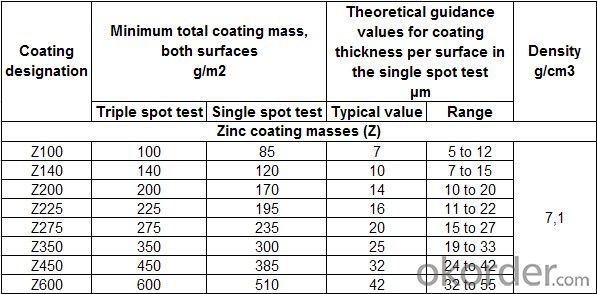

Coating mass