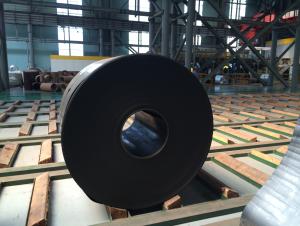

CRC full hard

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | Grade: | Thickness: | |||

| Place of Origin: | Brand Name: | Model Number: | |||

| Type: | Technique: | Surface Treatment: | |||

| Application: | Special Use: | Width: | |||

| Length: | Certificate: | steel full hard sheet: | |||

| Payment: | Packing: | Export to: |

Packaging & Delivery

| Packaging Detail: | Standard seaworthy packing or as required |

| Delivery Detail: | within 20days after received payment in advance,or L/C confirmed |

Specifications

crc spcd steel full hard sheet

1.Grade:SPCC SPCD,SPCE,dc01-dc06

2.used in structure,steel drum,automobile

- Q: What are the different types of steel coil loading and unloading devices?

- There are various types of steel coil loading and unloading devices that are commonly used in industrial settings. Some of the main types include coil lifters, coil hooks, coil grabs, and coil transfer carts. These devices are designed to safely and efficiently handle steel coils during the loading and unloading process, ensuring smooth operations and minimizing the risk of accidents or damage to the coils.

- Q: What are the different types of steel coil packaging materials used during processing?

- Some of the different types of steel coil packaging materials used during processing include steel strapping, plastic strapping, stretch film, shrink wrap, and coil covers.

- Q: What are the environmental considerations when using steel coils?

- Some environmental considerations when using steel coils include the extraction and processing of raw materials, energy consumption during production, and the potential for air and water pollution. Additionally, the disposal of steel coils at the end of their life cycle should also be taken into account to minimize waste and promote recycling.

- Q: How are steel coils used in the manufacturing of shipping containers?

- Steel coils are used in the manufacturing of shipping containers as they provide strength, durability, and structural integrity. These coils are transformed into sheets, which are then cut, shaped, and welded to construct the container's body and roof panels. The steel coils ensure that the container can withstand the rigors of transportation, protect the cargo inside, and endure various weather conditions.

- Q: What are the dimensions of a steel coil?

- The dimensions of a steel coil can vary depending on several factors such as the intended use, manufacturer specifications, and industry standards. However, common dimensions for steel coils typically include variations in width, thickness, and weight.

- Q: Can steel coils be coated with holographic patterns?

- Yes, steel coils can be coated with holographic patterns. This coating process involves applying a thin layer of holographic material onto the surface of the steel coils, creating a visually striking and distinctive holographic pattern.

- Q: What are the different methods of surface treatment for steel coils?

- There are several methods of surface treatment for steel coils, including hot-dip galvanizing, electro-galvanizing, chromating, and painting.

- Q: I'm pretty sure that this topic has been beaten to death by now. But, I still can't get a definite answer. With stainless steel, you get better corrosion resistance, and you will hold and edge longer. With carbon steel, you will hold a sharper edge, and you could forge a knife blade longer than 2 ft without breakage. I'm personally a fan of stainless steel ( the 440 grade stuff ), just because it seems to hold up to use and abuse better in the long run. HOWEVER, I have NEVER had a factory made knife break on me. I don't think that they would try to sell you a knife that didn't do what it was meant to do, at least to a reasonable degree. (I work for a living, and can't afford a custom $600 knife.) What do you think? Is this a pointless topic? Will there ever be a winner?

- I hate stainless steel! I hate shiny blades also! When I was a kid knifes were awesome! You could actually sharpen them! :) If we bought a new knife we would take an orange and slice it and leave the juice on the blade to purposefully darken it. If you had a shiny blade that looked like stainless you were not cool. :) I think most anyone who had an old knife from back in the 70's or before would agree that these new stainless knives are crap. I have not seen anything perform close to the old blades in stainless. Today I bought a case CV Sod Buster hoping it will perform like the old knives. What reading I have done the Chrome Vanadium is supposed to be like the old steel. I sure hope it is. Now to find some fruit to get rid of this annoying shiny blade! :)

- Q: Can steel coils be coated with abrasion-resistant materials?

- Yes, steel coils can be coated with abrasion-resistant materials. These materials are applied to the surface of the steel coils to enhance their resistance to wear and tear caused by friction, impact, or scratching. The abrasion-resistant coating provides a protective layer that helps prolong the lifespan and durability of the steel coils.

- Q: Is a steel plate the same as a steel coil?

- Generally speaking, they can be used interchangeably, and the purchase price of the plate is slightly cheaper.

Send your message to us

CRC full hard

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords