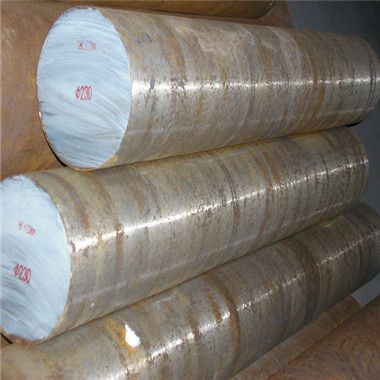

Cr12 Steel Round Bars D3 Galvanized Round Bars Din1.2080 Tool Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,JIS,GB,BS,DIN,API,EN,ASTM

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,CE

Thickness:

as required

Length:

as required

Net Weight:

as required

| Cr12 Steel Round Bars D3 Galvanized Round Bars Din1.2080 Tool Steel | |||||||||||

| Comparative standard | Grade | C | Si | Mn | Cr | Mo | V | W | P | S | Ni |

| GB | Cr12 | 2.00-2.30 | ≤0.40 | ≤0.40 | 11.5-13.0 | - | - | - | ≤0.030 | ≤0.030 | - |

| AISI | D3 | 3.00-2.35 | 0.10-0.60 | 0.20-0.60 | 11.0-13.5 | - | ≤1.00 | ≤1.00 | ≤0.030 | ≤0.030 | - |

| W-Nr. | 1.2080 | 1.90-2.20 | 0.10-0.60 | 0.20-0.60 | 11.0-13.0 | - | - | - | ≤0.030 | ≤0.030 | - |

| DIN | X210Cr12 | ||||||||||

| BS | BD3 | 1.90-2.30 | ≤0.60 | ≤0.60 | 12.0-13.0 | - | ≤0.50 | - | ≤0.030 | ≤0.030 | - |

| JIS | SKD1 | 1.90-2.20 | 0.10-0.60 | 0.20-0.60 | 11.0-13.0 | - | ≤0.30 | - | ≤0.030 | ≤0.030 | - |

| KS | STD1 | 1.80-2.40 | ≤0.40 | ≤0.60 | 12.0-15.0 | ≤0.30 | - | ≤0.030 | ≤0.030 | - | |

| Dimensions | |||||||||||

| Round bar | |||||||||||

| Dia:20mm~650mm | Length:2000mm~5800mm | ||||||||||

| Flat bar | |||||||||||

| Thickness:20mm~650mm | Length:2000mm~5800mm | ||||||||||

| *Dimensions can be customized | |||||||||||

| Heat Treatment | |||||||||||

| Hardness | 61~54HRC | - | |||||||||

| Anneal | 870-900°C | ≤217-255HBW | |||||||||

| Quenching | 930-980°C | oil cooling | |||||||||

| Tempering | 200-540°C | 61-54HRC, tempering twice | |||||||||

| Detail information | |||||||||||

| Process | EAF+LF+VD+(ESR)+Forging+(Rolling)+Annealing Condition (optional) | ||||||||||

| Delivery Condition | Hot forged+Rough machined/turned surface | ||||||||||

| Technical Data | According to customer’s requirements of chemical composition, physical properties and mechanical testing | ||||||||||

| Ultrasonic Test | Ultrasonic test according to SEP 1921-84 G3 D/d E/d | ||||||||||

| Applications | |||||||||||

| Hot extrusion dies, forging die forging hammer, forging press die, precision forging die well as aluminum, copper and alloys die-casting mold. | |||||||||||

| Relevant documents | |||||||||||

| Contract Documents | Contract, Debit Note, PI(Performa Invoice) | ||||||||||

| Certifications | SGS, ISO9001-2008, UT(Ultrasonic Test), CO,MTC | ||||||||||

- Q: What are the advantages of using nickel-aluminum alloy steel round bars?

- There are several advantages of using nickel-aluminum alloy steel round bars. Firstly, nickel-aluminum alloy steel round bars offer excellent corrosion resistance. This makes them suitable for applications in environments where the material is exposed to moisture, chemicals, or extreme temperatures. The corrosion resistance helps prolong the lifespan of the round bars and reduces the need for frequent maintenance or replacement. Secondly, nickel-aluminum alloy steel round bars exhibit high strength and toughness. This makes them ideal for use in structural applications that require a durable and reliable material. The high strength of these round bars enables them to withstand heavy loads and impacts without deforming or breaking, ensuring the structural integrity of the application. Additionally, nickel-aluminum alloy steel round bars have good heat resistance. They can withstand high temperatures without losing their mechanical properties, making them suitable for use in applications that involve heat or thermal cycling. This heat resistance also allows the round bars to maintain their shape and strength under extreme temperature variations. Moreover, nickel-aluminum alloy steel round bars have excellent machinability. They can be easily cut, drilled, and shaped into various forms, making them versatile for different applications. The machinability of these round bars reduces manufacturing time and costs, as well as enables customization to specific design requirements. Furthermore, nickel-aluminum alloy steel round bars have good weldability. They can be easily welded or joined to other materials without compromising their mechanical properties. This allows for the construction of complex structures or assemblies that require different materials to be joined together. Overall, the advantages of using nickel-aluminum alloy steel round bars include corrosion resistance, high strength and toughness, heat resistance, good machinability, and weldability. These properties make them a reliable and versatile choice for a wide range of applications in various industries such as aerospace, automotive, construction, and marine.

- Q: What is the difference between the heat treatment of cold drawn round steel and the heat treatment of wrought round steel?

- Solution heat treatment: the alloy is heated to a single phase at high temperature to maintain constant temperature, so that the excess phase is fully dissolved in the solid solution, and then cooled rapidly to obtain the heat treatment process of supersaturated solid solution.

- Q: Can steel round bars be used in the manufacturing of architectural features?

- Yes, steel round bars can certainly be used in the manufacturing of architectural features. Steel is a versatile and durable material that can be shaped and formed into various architectural elements such as columns, beams, handrails, and decorative features. Its strength and resistance to corrosion make it suitable for both structural and decorative purposes in the construction of buildings and other architectural designs.

- Q: What are the different types of steel round bar surface treatments used in the automotive industry?

- In the automotive industry, the most common types of steel round bar surface treatments used are galvanization, electroplating, and powder coating. Galvanization involves coating the steel with a layer of zinc to protect it from corrosion. Electroplating is a process where a thin layer of another metal, such as chrome or nickel, is applied to the steel surface for enhanced aesthetics and protection. Powder coating, on the other hand, involves applying a dry powder to the steel surface and then curing it under high heat to create a durable and attractive finish. These surface treatments help improve the durability, appearance, and overall performance of steel round bars used in automotive applications.

- Q: What are the maximum allowable stresses for steel round bars?

- The maximum allowable stresses for steel round bars depend on various factors such as the grade of steel, the type of loading, and the design code being followed. In general, the maximum allowable stress for steel round bars is determined by the yield strength of the steel. The yield strength is the stress at which permanent deformation or yielding of the material occurs. Different grades of steel have different yield strengths. For example, mild steel typically has a yield strength of around 250 MPa (megapascals), while high-strength low-alloy (HSLA) steel can have a yield strength of up to 550 MPa. To determine the maximum allowable stress, typically a safety factor is applied to the yield strength. This safety factor takes into account uncertainties in material properties, loadings, and potential variations in manufacturing processes. The safety factor can vary depending on the application and design code being followed. For example, in structural steel design, the American Institute of Steel Construction (AISC) specifies a safety factor of 1.67 for the yield strength. This means that the maximum allowable stress would be the yield strength divided by 1.67. It is important to consult relevant design codes, standards, or engineering specifications for specific applications to determine the appropriate maximum allowable stresses for steel round bars.

- Q: Can steel round bars be machined easily?

- Yes, steel round bars can be machined easily due to their excellent machinability properties.

- Q: What is the difference between carbon steel and stainless steel round bars?

- Carbon steel and stainless steel round bars differ primarily in their composition and properties. Carbon steel is primarily made up of iron and carbon, with trace amounts of other elements. It is known for its strength and durability, making it ideal for various applications in industries such as construction and automotive. Carbon steel round bars are generally more affordable than stainless steel round bars. Stainless steel, on the other hand, is a steel alloy that contains at least 10.5% chromium. This addition of chromium gives stainless steel its unique properties, including corrosion resistance. Stainless steel round bars are highly resistant to rust and staining, making them suitable for applications in environments exposed to moisture and chemicals. They are commonly used in industries such as food processing, medical equipment, and marine applications. Due to the chromium content, stainless steel round bars are generally more expensive than carbon steel round bars. However, the added cost is justified by their superior corrosion resistance and aesthetic appeal. Stainless steel also offers different grades and finishes, allowing for customization based on specific requirements. In summary, the main difference between carbon steel and stainless steel round bars lies in their composition and properties. Carbon steel is strong and affordable, while stainless steel offers corrosion resistance and comes in various grades and finishes. The choice between the two depends on the specific application and the desired properties required for the project.

- Q: How are steel round bars tested for quality and compliance?

- Steel round bars are tested for quality and compliance through various assessment methods such as visual inspection, dimensional measurements, chemical composition analysis, and mechanical property testing. These tests ensure that the bars meet the required standards, strength, and durability for their intended applications.

- Q: What are the different types of steel round bar alloys for improved machinability and strength?

- There are several different types of steel round bar alloys that are specifically designed to offer improved machinability and strength. These alloys are commonly used in various industries where the ability to machine components efficiently while maintaining high tensile strength is crucial. Some of the most popular steel round bar alloys for improved machinability and strength include: 1. 12L14: This alloy contains lead, which acts as a lubricant during machining, resulting in improved chip formation and reduced tool wear. It offers excellent machinability and good strength, making it suitable for applications that require intricate machining processes. 2. 4140: Also known as "chromoly" steel, this alloy contains chromium and molybdenum, which enhance its strength and hardenability. 4140 steel round bars are widely used in applications that require high tensile strength, such as automotive parts, shafts, and gears. 3. 8620: This alloy is a low-alloy nickel-chromium-molybdenum steel that offers a combination of high strength and good toughness. It can be easily machined and is often used in applications that require case-hardening, such as gears, shafts, and fasteners. 4. 1018: Known as "cold-rolled" or "cold-finished" steel, 1018 is a low-carbon steel alloy that offers good machinability and weldability. It is commonly used in applications where precise and smooth finishes are required, such as in the manufacturing of bolts, screws, and hydraulic fittings. 5. 52100: This alloy is a high carbon, chromium-bearing steel that is primarily used in the manufacturing of bearings and other high-wear applications. It offers excellent hardness, wear resistance, and machinability, making it suitable for components that require high strength and durability. These are just a few examples of the different types of steel round bar alloys available for improved machinability and strength. The choice of alloy depends on the specific requirements of the application, such as the desired strength, machinability, and durability. Consulting with a materials engineer or supplier can help determine the most suitable alloy for a particular use case.

- Q: What are the advantages of using nickel-silicon alloy steel round bars?

- Using nickel-silicon alloy steel round bars offers several advantages. Firstly, this alloy provides excellent resistance to corrosion and oxidation, making it highly durable and suitable for various applications in harsh environments. Secondly, the presence of nickel enhances the material's strength and toughness, making it ideal for use in high-stress applications. Additionally, the silicon content improves the alloy's heat resistance, allowing it to withstand elevated temperatures without significant deformation. Overall, nickel-silicon alloy steel round bars offer a combination of corrosion resistance, strength, toughness, and heat resistance, making them a preferred choice in numerous industries such as aerospace, automotive, and chemical.

Send your message to us

Cr12 Steel Round Bars D3 Galvanized Round Bars Din1.2080 Tool Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords