CPC Low Sulfur Petroleum Coke FC 98.5% Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 50kg/bag 100kg/bag 1000kg/bag Or according with client need |

| Delivery Detail: | 2 weeks |

Specifications

CPC Low Sulfur Petroleum Coke FC 98.5% Cheap Price

Petroleum coke products can be divided into needle coke, sponge coke, projectile coke and coke breeze four kinds.

Calcined Petroleum Coke

F.C.: 98.5%MIN

ASH: 0.8% MAX

V.M.: 0.7%MAX

S:0.5%MAX

Moisture: 0.5%MAX

Structure

CPC Low Sulfur Petroleum Coke FC 98.5% Cheap Price

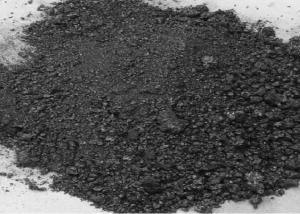

Shape: granule

Dimensions: 0-1mm, 1-5mm, 1-6mm, 2-8mm, etc

Product Type: Carbon Additive

C Content (%): 98-99.5% MIN

Working Temperature: -

S Content (%): 0.5%-0.7%MAX

Ash Content (%): 0.7%MAX

Volatile:0.8%MAX

Moisture: 0.5% MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

Feature

CPC Low Sulfur Petroleum Coke FC 98.5% Cheap Price

Physics and chemistry performance :

Unit | Index | |||||

No.1 | No.2 | No.3 | ||||

Density | g/cm3 | 2.04 | 2.00 | 2.00 | ||

sulphur content | %≤ | 0.5 | 1.0 | 2.5 | ||

volatility | %≤ | 0.5 | 0.5 | 0.5 | ||

ash content | %≤ | 0.5 | 0.5 | 0.5 | ||

moisture | %≤ | 0.3 | 0.5 | 0.5 | ||

charcoal | %≤ | 98.5 | 98.0 | 98.0 | ||

Image

CPC Low Sulfur Petroleum Coke FC 98.5% Cheap Price

FAQ:

CPC Low Sulfur Petroleum Coke FC 98.5% Cheap Price

How to classify calcined petroleum coke?

1) According to difference of sulfur content, can be divided into high sulfur coke (sulfur content more than 4%), sulphur in coke sulfur content (2% 4%) and low sulfur coke (sulfur content below 2%).

2) Petroleum coke products can be divided into needle coke, sponge coke, projectile coke and coke breeze four kinds:

3) Needle coke, has obvious needle-like structure and fiber texture, mainly used for steel-making in high power and ultra-high power graphite electrode. As a result of needle coke in sulfur content, ash content, volatile matter and true density and so on have strict quality requirements, so the production process of needle coke and raw materials have special requirements.

4) The sponge coke, high chemical reactivity, low content of impurities, mainly used in the aluminum industry and carbon industry.

5) Focal or spherical coke: the projectile shape is round, diameter 0.6-30 mm, usually from the production of high sulphur, high asphaltic residual oil, can only be used as industrial fuel power generation, cement etc.

6) Coke breeze: fluidized coking process, the fine particles (0.1- 0.4 mm) in diameter, high volatile, high expansion coefficient, cannot be directly used for electrode preparation and carbon industry.

Advantage:

CPC Low Sulfur Petroleum Coke FC 98.5% Cheap Price

1. High quality and competitive price.

2. Timely delivery.

3. If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: How do fossil fuels release carbon into the atmosphere?

- Fossil fuels release carbon into the atmosphere through the process of combustion. When fossil fuels like coal, oil, and natural gas are burned for energy production, carbon dioxide (CO2) is released as a byproduct. This CO2 is a greenhouse gas that traps heat in the Earth's atmosphere, contributing to global warming and climate change.

- Q: What are carbon sinks?

- Carbon sinks are natural or artificial reservoirs that absorb and store carbon dioxide from the atmosphere. They play a crucial role in mitigating climate change by reducing the concentration of greenhouse gases in the atmosphere. Carbon sinks can be found in various forms, including forests, oceans, wetlands, and soil. Forests are the largest and most well-known carbon sinks. Through the process of photosynthesis, trees absorb carbon dioxide and convert it into oxygen, storing the carbon in their trunks, branches, and roots. Oceans are also significant carbon sinks, as they absorb about a quarter of the carbon dioxide emitted by human activities. Algae, phytoplankton, and other marine organisms capture carbon through photosynthesis and convert it into biomass. Wetlands, such as marshes and swamps, are another important carbon sink. These areas store enormous amounts of carbon in their vegetation and soil, preventing it from being released back into the atmosphere. Additionally, soil acts as a carbon sink by absorbing and storing carbon through the decomposition of organic matter and the action of microorganisms. Artificial carbon sinks, like carbon capture and storage (CCS) technologies, are being developed to further combat climate change. CCS involves capturing carbon dioxide emissions from power plants and industrial facilities and storing them underground or repurposing them for other uses. While these technologies are still in the early stages, they have the potential to significantly reduce carbon emissions and help stabilize the climate. Overall, carbon sinks are essential for maintaining the balance of carbon dioxide in the atmosphere and preventing its accumulation, which would contribute to global warming. Preserving and restoring natural carbon sinks, such as forests and wetlands, is crucial for mitigating climate change, while developing and implementing artificial carbon sinks can further aid in reducing greenhouse gas emissions.

- Q: What are carbon-based superconductors?

- Carbon-based superconductors are a type of material that exhibit superconductivity, a phenomenon where electrical resistance drops to zero at low temperatures. Unlike conventional superconductors, which are typically metallic elements or alloys, carbon-based superconductors are composed primarily of carbon atoms. These materials are known for their unique structure and properties, which make them highly efficient conductors of electricity when cooled below a certain critical temperature. Carbon-based superconductors can be categorized into two main types: organic superconductors and fullerene superconductors. Organic superconductors are made up of carbon-based molecules, such as organic salts or polymers, which form a crystal lattice structure. These materials have been extensively studied and have shown promising superconducting properties at low temperatures. Fullerene superconductors, on the other hand, are composed of carbon molecules arranged in a specific cage-like structure, called fullerenes. The most well-known fullerene is C60, also known as a buckyball, which consists of 60 carbon atoms arranged in a soccer ball-like shape. By doping these fullerene cages with certain elements, such as alkali metals or transition metals, their superconducting properties can be enhanced. What makes carbon-based superconductors particularly interesting is their potential for high-temperature superconductivity. While most conventional superconductors require extremely low temperatures close to absolute zero (-273.15°C or -459.67°F) to exhibit superconductivity, some carbon-based superconductors have been found to retain their superconducting properties at relatively higher temperatures. This property is crucial for practical applications, as it allows for easier cooling and opens up possibilities for widespread use of superconductivity in various fields, including energy transmission, magnetic levitation, and quantum computing. However, it is important to note that carbon-based superconductors are still an active area of research, and many challenges remain in understanding their mechanisms and improving their superconducting properties. Nonetheless, the discovery and exploration of these materials hold great promise for advancing the field of superconductivity and enabling new technological breakthroughs.

- Q: What is the symbol for carbon?

- "C" is the symbol representing carbon.

- Q: How does carbon affect the quality of indoor air?

- The quality of indoor air can be significantly affected by carbon. Carbon dioxide (CO2) is a major contributor to carbon in indoor air and is produced when humans and animals respire. High levels of CO2 can cause discomfort, including drowsiness, headaches, and difficulty concentrating. Another carbon compound that can be found in indoor air is carbon monoxide (CO), which is mainly present due to incomplete combustion of fossil fuels in stoves, fireplaces, and furnaces. Carbon monoxide is extremely toxic and can be life-threatening if it reaches high concentrations. In addition to these direct sources of carbon, volatile organic compounds (VOCs) can also impact indoor air quality. VOCs like formaldehyde, benzene, and toluene are released from various sources such as building materials, furniture, cleaning products, and tobacco smoke. These VOCs can have harmful effects on health, including irritation of the eyes, nose, and throat, headaches, dizziness, and in some cases, long-term health risks such as cancer. To maintain good indoor air quality, it is crucial to monitor and control the levels of carbon compounds in the air. Adequate ventilation is essential to ensure fresh air circulation and reduce the concentration of CO2 and other pollutants. Regular maintenance and inspection of appliances that burn fuel can prevent the accumulation of carbon monoxide. Choosing low-VOC or VOC-free materials and products, as well as refraining from smoking indoors, can help minimize the emission of harmful carbon compounds.

- Q: How does carbon affect the formation of landslides?

- Carbon does not directly affect the formation of landslides. However, the presence of carbon in the form of organic matter can contribute to the stability of slopes as it plays a role in soil structure and moisture retention.

- Q: How does carbon affect the quality of soil?

- Soil quality is greatly influenced by carbon, which plays a vital role in its determination. When dead plants and animals decompose, they release carbon into the soil, a process known as carbon sequestration. This process is crucial for maintaining the fertility and health of the soil. The presence of carbon in the soil is beneficial for the growth of microorganisms such as bacteria and fungi. These microorganisms contribute to the breakdown of organic matter and the recycling of nutrients. Their presence helps create a fertile soil environment, ensuring that plants can absorb essential nutrients. Moreover, carbon in the soil improves its structure and its ability to hold water. It acts like a sponge, allowing the soil to retain moisture, which is essential for the growth and survival of plants. Carbon also prevents soil erosion by binding particles together, reducing the risk of nutrient loss and water runoff. Additionally, carbon enhances the soil's capacity to store and release nutrients. It acts as a reservoir for elements like nitrogen, phosphorus, and potassium, gradually releasing them to plants over time. This nutrient cycling is vital for sustaining healthy plant growth and productivity. However, modern agricultural practices, including excessive tilling, overuse of synthetic fertilizers, and deforestation, have caused a significant decline in soil carbon levels. This loss of carbon negatively impacts soil quality, resulting in decreased fertility, increased erosion, and reduced water-holding capacity. To counteract these negative effects, it is essential to adopt sustainable agricultural practices that focus on carbon sequestration and soil conservation. These practices involve reducing tillage, incorporating cover crops, practicing crop rotation, and using organic fertilizers. By increasing carbon levels in the soil, we can improve its quality, promote plant growth, and ensure the long-term sustainability of our agricultural systems.

- Q: What type of carbon copy sheet can be printed on? How many copies?

- Printed in carbon free carbon paper, usuallyUpper: whiteMedium: RedNext: yellowMainly depends on how much you want to print. Generally 100 pages, such as:One copy of the two couplet is 50 copies.One copy of the triad is 33 copies.One copy of the quadruple is 25 copies.This is a five of the 20.

- Q: How does carbon impact the prevalence of heatwaves?

- Carbon impacts the prevalence of heatwaves by contributing to the greenhouse effect. When carbon dioxide and other greenhouse gases are released into the atmosphere, they trap heat from the sun, leading to a rise in global temperatures. This increase in temperature makes heatwaves more frequent, intense, and longer-lasting, posing significant risks to human health, ecosystems, and infrastructure.

- Q: What does carbon burning mean?

- Put the burning carbon under the iron plate and make a copy of it on the iron plate, that is, carbon burning!

Send your message to us

CPC Low Sulfur Petroleum Coke FC 98.5% Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords