Countersunk Cap Routel for Spider AT13 30-40mm glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

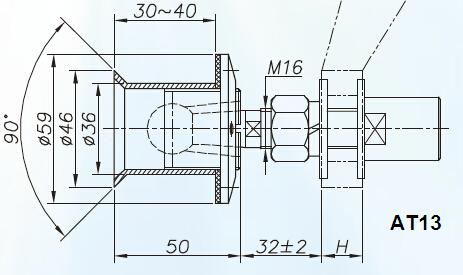

Product Name | Countersunk Cap Routel for SpiderAT13 30-40mm glass |

Material | Stainless Steel 304/316. |

Finish | Natural |

Glass thickness | 30~40mm |

Bolt Size | M16 |

Max. axial bearing capacity | 6000N |

Max. Radial Bearing capacity | 2500N |

Adjustable angle | ±10 degree |

Min Order | 100piece/ pieces |

Packing | Inner Box + Carton Box |

Supply capacity | 100000 piece/ pieces per month |

Delivery time | 20~35 days after receipt of down payment |

Export market | Asia, America, Europe, Africa, markets. |

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Pictures:

- Q: Does anyone need a point-like glass curtain wall?

- According to the facade decorative effect is divided into flat head point of the glass curtain wall and convex point of the glass curtain wall. According to the bearing structure is divided into glass ribs point glass curtain wall, steel structure point glass curtain wall, steel rods point of the glass curtain wall and steel cable point glass curtain wall.

- Q: Viagra Tile 8h005 price

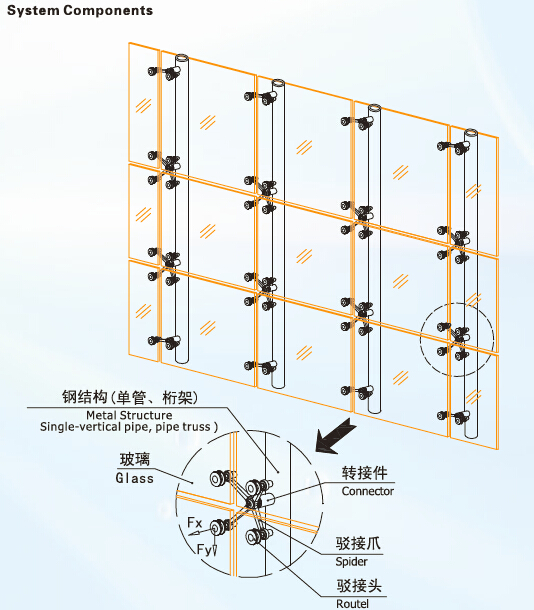

- The point-type glass curtain wall is composed of splice joints, splicing jaws, adapters and other components, the main claw claw as a support link joints, and transfer load to a fixed support structure on the system

- Q: Afraid to stand under the building with a glass curtain wall Today to the digital square, walked, suddenly heard a sound, and then a look at the front of the meter on the second floor of the glass split on the second floor, just under the two people passing. A time screaming again and again. Sent to the nearby hospital, blood flow all the way ... ... I also decorated the company for two years, really do not understand why so many people like glass curtain wall now. Personally feel that it can only look at the top, but also unsafe (old in the accident), and dirty (high difficult to clean up).

- Now people like simple, and the light is very good, you can save energy, if it is the wall, then how much to waste electricity Although he has light pollution, but still like

- Q: How many errors can be made by welding the splicing jaws

- To be reasonable at the beginning of the adapter and the steel frame between the contacts designed, I make a simple example: Now there are a lot of steel frame is welded with a round tube, that adapter The base in the production of the time also need to be cut into the arc, so that steel pipe can be better connected to the tube, while reducing the interface of the degree of restraint, and secondly, reasonable arrangement of welding order to reduce the welding stress, Welding at the same time can reduce the heat generated when welding cracks. Welding starting point and the mouth is easy to produce cracks, conditional welding joints should be at the plus arc plate and arc plate. If you can not use the arc plate, the best use of attenuation current arc, and fill the crater. At the same time in the welding process in order to reduce the weld cracks, as far as possible the use of small lines of energy and cross-section of the welding point. If the process of welding found in the leak, if not serious, then gently knock with a hammer may be just fine. To avoid this is best to the workers carefully, in the welding when the cautious point of these problems can be avoided.

- Q: The construction of the people say to make a certain slope, because the rain to the direction of their own home to the flow of the station Will the beam be loaded with I-beam? Workers say 50 * 100 square tube on the line

- Recommendation: do the sun room must choose a regular company, need to have the design and calculation capabilities, through the design of the design calculation to ensure the safety of the structure, which is necessary. There are regular company material control will be better, construction and installation will be more standardized after use, with the rest assured.

- Q: What are the accessories of the point-supported glass curtain wall?

- Point-type glass curtain wall accessories are stainless steel curtain wall adapter, split joints, split claws, glass clip, handrail pieces, rain canopy accessories, support rods, rods, cable, stainless steel mini cable and so on.

- Q: How is the glass curtain wall attached to the steel frame fixed on the steel frame

- Steel structure point curtain wall cylindrical adapter seat welded to the steel structure, the splicing claw screw to the adapter seat, the joint and then fixed to the splicing claw

- Q: Is there a stainless steel splicing claw with the same price but cheaper manufacturers?

- You can find some manufacturers to compare the price, the other material must be standard, not light map cheap. I recently ordered a project called Jiangsu Jie Chen manufacturers, the price is cheap enough, the material can meet the standard.

- Q: What is the difference between double steel safety glass and insulating glass in steel canopy

- Light steel glass canopy focus on just the material for the light steel, tempered glass canopy focus on the glass material for the tempered glass, are glass canopy, but the name of the focus is not the same, light steel glass canopy glass can also be used glass

- Q: I do not understand the hope that my friends guide the guidance teach me, the general is divided into 150 160 type 200 type 220 type 250 type (4 claw) a set of refers to the splicing claws +4 turn joints +1 turn Parts There is the corresponding model with the corresponding splicing? Or with the model has nothing to do with the folder of the glass? Such as 150 can be used to replace the type of 200 can not use? Who explained the next

- The same series of models of the splicing jaws can only be equipped with the same series of models of the joints, and glass has nothing to do, and the glass aperture is determined by the joints. The series of splicing claws is twice the distance between the center of the hole of the spliced joint and the center of the hole of the adapter. The distance between the center of the hole of the 250-piece claw fitting and the hole center of the adapter is 125mm, twice the 250mm, 250 series.

Send your message to us

Countersunk Cap Routel for Spider AT13 30-40mm glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 Piece/Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches